Release note Software version 5.24.x

Applicable for e-Series and UR-Series

For latest release notes of PolyScope X, please refer to Release note Software version 10.11.x

Date of release: October 16th 2025.

Download HERE

SW 5.24.0 Release Notes

Release Versions:

- UR Software Update: 5.24.0

- URSim Linux: 5.24.0

- URSim Virtual Machine: 2.2.x

- User Manuals: 5.24.0

Key Features

- Improved usability of Constrained Freedrive

PolyScope GUI

New safety-rated output function: 3-position Enabling Stopped

Two new safety output functions are now available in Installation → Safety → I/O under the Output section.

- 3-Position Enabling Stopped

- Signal is HIGH when a three-position stop is active, otherwise LOW

- Not 3-Position Enabling Stopped

- Signal is LOW when a three-position stop is active, otherwise HIGH

These two new output functions allow the safety-rated configurable outputs to send a high or low signal, depending on the state of an attached three position enabling device. To use the two new safety output functions, the installation should also be configured with either a Teach Pendant with 3-Position Enabling Device or an external 3-Position Enabling Device configured through the Safety Input Functions.

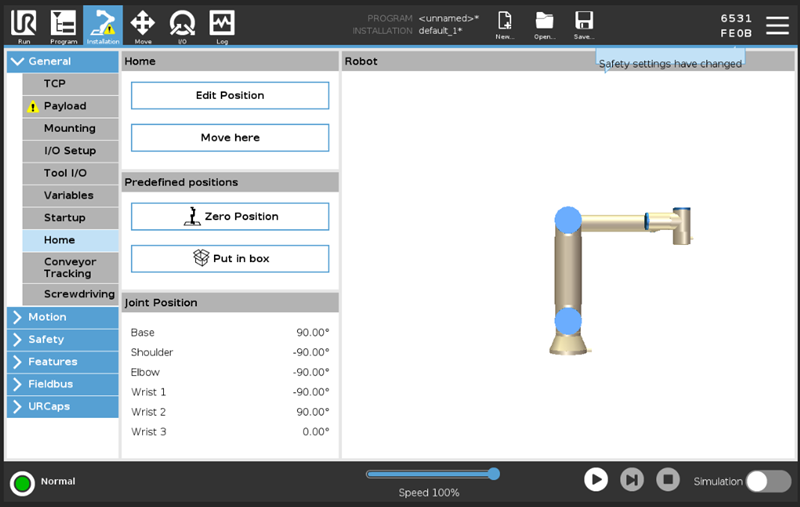

Put in Box predefined position

new predefined position has been added to the Installation → Home page under a new Predefined positions section, replacing the previous Put in Box program available on some robots.

Put in Box can be used to move the robot into a compact position that is suitable for transportation. The Put in Box sequence consists of an initial movement to the Zero Position, followed by a movement in to the Put in Box position.

Improved usability of Constrained Freedrive

Constrained Freedrive has been significantly improved; In particular for tools with long TCP offsets, such as welding tools.

Freedrive is constrained, when movement on one or more axes are locked.

It is now easier to accurately position the tool.

The improvements are effective both when a guiding force is applied directly on the tool or to the robot arm.

Freedrive sensitivity could be adjusted by moving the speed slider. Lower speeds are better for fine-tuning tool position.

URCap Software Platform

Controller

- Introduce jerk_gain_scaling_set() and jerk_gain_scaling_get() builtins; Allow users to reduce system vibrations and achieve smoother motions in optimoveX and moveX (in combination with motion version 2).

Bug Fixes

PolyScope GUI

- Localized China systems have the regional language programming option enabled by default and optionally can switch to "English Programming".

- Until Tool Contact node correctly handles numerical values for the languages using comma as decimal separator.

Pallet Template

- Fixed issues with reteaching in the Pallet node. The referencePoint feature that is used as a reference for approach, tool action and exit point in the pallet node, is now based on the first item in the selected grid. This means that the referencePoint feature will be updated whenever the first item is adjusted. If the feature for the pallet is changed, this will also update the referencePoint based on the new position of the first item. The same changes are applied to the separator point and separator action. These changes ensure that the program tree always display where the robot will move to, at the first item in the pallet node also after reteaching.

- Fixed issue with path issues and unexpected kinematics in the Pallet node. The fix is to use the taught joint angles for qNear, which is used throughout the pallet node to find the inverse kinematics solution. Before qNear could be updated based on the active TCP, which could result in different program behavior between program runs, path issues or unexpected kinematics in the pallet node.

- Reteaching of items in existing pallet no longer causes unexpected positions.

- Unexpected kinematics causing wrong joint configuration for some TCP's.

Controller

- Fixed robot moving slower than expected under certain conditions when using movej and motion version 2.

Embedded/Safety system

- Fixed IMMI issue with faulting on timeout during first start-up after applying a safety configuration.

- Improved motion tracking on UR-Series when target is oscillating at slow speeds (e.g. during weld weaving).

- Fixed bug where joints having been originally delivered as spare part with software between SW5.6 and SW5.9.2 could not be updated directly to SW5.20 or newer.

- Improved motion performance at joint speeds below 800µrad/s in the base and shoulder of UR8 Long and UR15 robots.

previous RELEASE NOTES:

- Release Notes Software Version 5.23

- Release Notes Software Version 5.22

- Release Notes Software Version 5.21

- Release Notes Software Version 5.20

- Release Notes Software Version 5.19

- Release Notes Software Version 5.18

- Release Notes Software Version 5.17

- Release Notes Software Version 5.16

- Release Notes Software Version 5.15

- Release Notes Software Version 5.14

- Release Notes Software Version 5.13

- Release Notes Software Version 5.12

- Release Notes Software Version 5.11

- Release Notes Software Version 5.10

- Release Notes Software Version 5.9

- Release Notes Software Version 5.8

- Release Notes Software Version 5.7

- Release Notes Software Version 5.6

- Release Notes Software Version 5.5

- Release Notes Software Version 5.4

- Release Notes Software Version 5.3

- Release Notes Software Version 5.2

- Release Notes Software Version 5.1