CNC Machine Tending

Today’s manufacturers want to automate manual tasks with robots, but getting robots up and running is complex, expensive, and can leave you feeling overwhelmed. At Robotiq, we believe robots should simplify your life, not make it more complicated. Working with manufacturers globally (and being one ourselves!), we understand the challenges of maintaining quality, delivering on time, and keeping costs down amidst the labor shortage. Since 2008, Robotiq has pursued its mission of freeing human hands from repetitive tasks by enabling more than 13,000 collaborative robots, or "cobots," worldwide. From SMEs to multinational companies, we're helping manufacturers simplify their processes with easy-to-use automation solutions.

Manufacturers want their operations to run smoothly with as little downtime as possible. Automation is often considered, but quickly dropped because of the perception that it is complex and expensive. At Robotiq, we tackle this challenge by making solutions that are actually easy to use. The Machine Tending Solution is the only solution you need to automate your CNC machines. Combined with our worldwide distribution network, you can automate a CNC machine in hours instead of weeks.

How can we back that bold statement?

The new version of Machine Tending Copilot was developed with the operator in mind. Cobots are simpler to use than industrial robots, but a machine-tending application is still complicated. For this reason, traditional programming can quickly get overwhelming. That’s why our Machine Tending Copilot software guides users through programming from start to finish. With key waypoints and action menus, programming is 75% faster than with traditional methods. Once the key waypoints are created, the user is guided to refine each operation with our action menus—from picking the workpiece to defining pre-programmed cleaning patterns . Since we know that every second counts in the manufacturing process, we’ve created the Smart Move. Using the Machine Tending Copilot algorithm, the robot finds the optimal path from point A to point B without colliding with the environment. This technology can shave up to 15% off your cycle time and shortens setup and downtime, which ultimately gets the machine up and running faster. Earn a quick ROI even with high-mix, low-volume automation; with accelerated program creation, Copilot does the hard work for you.

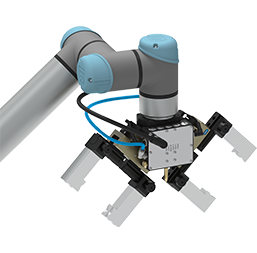

External modules manage communication with the machine interface, so there is no need to open or alter the machine in any way. This approach, which is similar to the way an operator would do the job, makes our solution compatible with almost all machine brands and models. We supply an external control box and pneumatic enclosure to accelerate installation.

Custom solutions can be costly and time-consuming to integrate, but the Machine Tending Solution takes less than two hours to deploy and machine your first part—no coding experience required.

Elevate your workforce with easy-to-use robot solutions that do the work for you.