ActiNav v1.6.0 Release announcement

Date Created: February 24th, 2022.

Product(s) Affected: ActiNav Next-generation Machine Loading

Link to the bulletin in PDF format

Link to ActiNav v1.6.0 download page

Link to technote: How to update ActiNav

Summary

Universal Robots is pleased to announce the new ActiNav version 1.6. This new version doubles down on ActiNav’s purpose: make unattended, flexible production a reality, with major enhancements in both key areas:

- Higher part flexibility: ActiNav is now able to detect and locate an even wider range of parts, with higher confidence and accuracy, thanks to new features like advanced matching parameters, sensor presets and a whole new perception flow.

- Increased unattended run duration: Bin shuffle unlocks lights-out production in situations where parts tend to overlap and interlock, while automatic bin floor detection increases the number of parts detected and picked from lower layers, enabling ActiNav to run longer before needing a bin refill.

Additionally, ActiNav 1.6 brings improvements in usability and performance, ranging from faster re-scan to editable custom pose nodes. These enhancements will empower users to create better-performing ActiNav applications more efficiently.

Version 1.6 features and improvements

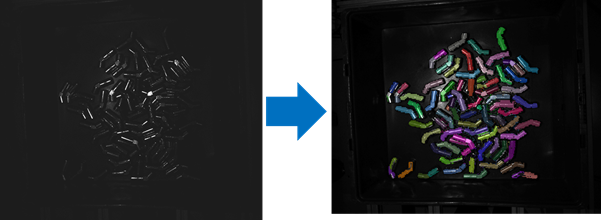

Automate feeding of cylinders and blocks with Continuous Surface perception flow:

ActiNav 1.6 adds a new perception flow called “Find continuous surface” on top of the two existing ones (volumetric and 3D edge). With Continuous Surface, ActiNav is able to isolate each part in the 3D scan by analyzing gaps between continuous surfaces in the bin. Once parts are segmented, it is much easier for ActiNav to find their position accurately. This new perception flow improves ActiNav’s performance with featureless parts, such as rods or raw blocks.

More accurately find more part types with advanced matching parameters:

When finding part matches in the 3D scan, ActiNav uses a set of parameters tuned to work with a wide range of parts. However, some parts can require fine-tuning of these parameters due to their shape or how they lay on the bin. By enabling users to tune these parameters, ActiNav can more reliably and accurately match a much wider range of parts.

Expand the range of part materials and environmental conditions with advanced sensor presets:

With ActiNav 1.6, users can easily create, select and store different sensor presets for each part, expanding even more the range of conditions under which ActiNav delivers top performance.

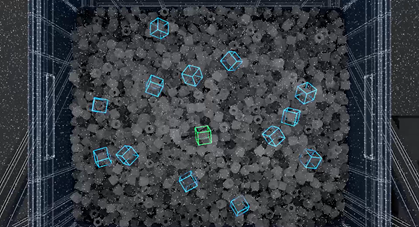

Unlock lights-out production with bin shuffle:

Certain part shapes are prone to produce overlaps or form compact groups inside the bin. The main challenge in these applications is finding ways of extracting such parts so that they can be placed into the machine later. To overcome these situations, stations require periodic manual operations to stir the bin or mechanical solutions like bin vibrators that rearrange the parts in more favorable layouts.

ActiNav 1.6 introduces a new alternative to solve these applications without additional hardware costs or worker intervention: bin shuffle. Bin shuffle is an alternative operation mode that ActiNav uses when it detects blocking part layouts. Instead of planning the full path to placing the part in the machine, ActiNav activates an alternative place rule to just extract some parts and redrop them in the bin again. Thanks to this, parts get rearranged and ActiNav can return to normal operation with optimal performance. All without human intervention or additional components.

Bin shuffle enables lights-out production in traditionally challenging scenarios that required periodic manual intervention. Early tests in real applications show that it can unleash ActiNav’s unattended operation capacity, going from requiring manual intervention every four hours, to working autonomously for full weekends (>40 hours), resulting in 10x machine uptime and autonomous production.

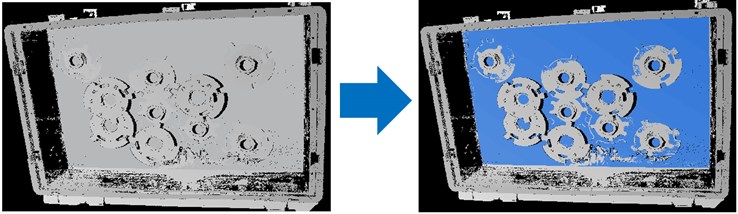

Increase bin clearing with automatic bin floor adjustment:

ActiNav 1.6 is able to find and pick more parts from each bin thanks to the new automatic bin floor adjustment.

A traditional challenge about locating parts with machine vision is to segregate parts from the surface underneath. The direct consequence is that the last layer of parts is normally not detectable, and therefore not pickable, especially in applications with thin parts or uneven bin surfaces.

With automatic bin floor adjustment, ActiNav can now analyze the 3D information to segregate the points belonging to parts from the bin surface underneath. This makes it possible to detect more parts more reliably, even in the last layer.

Additional UI enhancements

- Editable custom pose coordinates. Custom poses can now be numerically edited, which allows the user to define paths more efficiently and accurately.

- Joint position notation for robot poses. Custom robot poses are now displayed in joint rotations. This makes it clearer for users to use and edit this kind of poses.

- Robot-sensor alignment check. Users can now easily take a scan of the robot to get a quick, visual verification of this alignment.

- TCP position check. The tool configuration now includes a button to let users scan the tool and compare the robot’s TCP against the physical tool for a more accurate TCP definition.

Additional performance enhancements

- Up to 6x faster re-scan. ActiNav 1.6 drastically reduces the idle time it takes for the 3D sensor to trigger a re-scan, making it nearly immediate and slashing idle time.

- 3D sensor firmware and server updates. ActiNav 1.6 is compatible and tested with the latest sensor software, which includes several internal performance improvements.

- Data generation improvements for more efficient support. information collected by system logs has been optimized to generate more information taking less disk space, enabling faster and more effective technical support.

Version compatibility

NOTE: It is necessary to update PolyScope, sensor server and sensor firmware to the following versions for ActiNav 1.6.0 to have optimal performance.

- PolyScope v5.11.7 (Download link) – See the Settings section on PolyScope’s manual for instructions on how to update PolyScope

- Sensor server v1.2.31 (Download link) – Tech note on how to update the sensor's server

- Sensor firmware v1.2.31 (Download link) – Tech note on how to update the sensor firmware

NOTE: Part instances created in 1.6.0 are NOT backwards compatible with earlier ActiNav URCap versions.

ActiNav-optimized UR+ Products

The range of ActiNav-optimized UR+ components keeps growing to offer straightforward, high-performance solutions to complement your ActiNav stations.

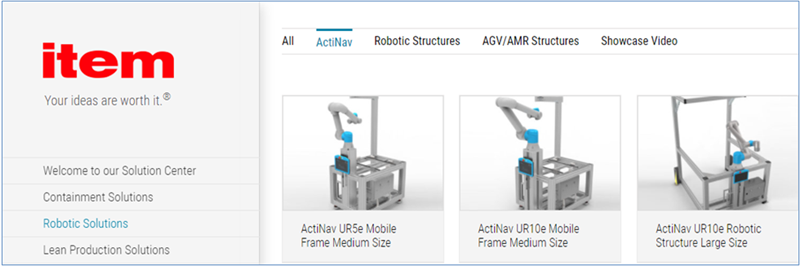

ActiNav-optimized UR+ frames

ITEM24 ActiNav frames

Item24 and ActiNav teams have collaborated in the creation of ActiNav customizable frames for three application combinations: ActiNav M + UR5e, ActiNav M + UR10e and ActiNav L + UR10e. These frames are available in Item24’s Robotic Solution catalogue. Additional services offered by ITEM24 include design assistance and frame pre-assembly.

Vention ActiNav frames

Vention has released two standard ActiNav frames for UR10e and a UR5e frame. These can be purchased directly from Vention as designed or these designs can be used as a starting point to create a customized frame.

ActiNav-optimized UR+ tools

Piab piCOBOT

The Piab piCOBOT is custom made for Universal Robots collaborative robots (UR3, UR3e, UR5, UR5e, UR10, UR10e and UR16e if not exceeding 7kg/15lbs) and boasts flexible setting options to perfectly match application needs. The ActiNav-optimized kit includes an angled head, 4x suction cups as well as coiled air hose management. piCOBOT includes UR software capabilities (URCaps) for quick and easy installation/implementation and programming, compatible with e-Series and CB-series. Learn more here.

Robotiq Hand-E

The Robotiq Hand-E is a reliable and easy to use gripper, designed for industrial automation. The new Bin Picking Finger Kit brings high gripping flexibility to the ActiNav bin picking system. Hand-E + BP Finger Kit allows the system to pick the parts in different ways (i.e., internal and external) for more flexibility. The Hand-E Grip Validation feature is connected with ActiNav, allowing the system to automatically retry a grasp if a part is not picked properly. Learn more here.

Magswitch CoBot SmartMapGrip E30

The Magswitch CoBot SmartMagGrip is specifically designed to work with UR e-series robots in bin picking and material handling of ferromagnetic parts. It incorporates all the same features as a typical Magswitch E-Series tool, including variable field output (VFO) and integrated sensing technology. The CoBot SmartMagGrip E30 is currently supported with direct integration to Universal Robots through the Tool IO connector with a URcap communicating via RS-485. Learn more here.

ActiNav Technical Documentation and Resources

- List of available ActiNav technical resources

- ActiNav documentation and downloads

- Link to ActiNav technical notes

UR Academy’s ActiNav Basic Training

The ActiNav team and the UR Academy team have partnered up to produce the new ActiNav Basic Training, leveraging the widely recognized UR Academy methodology.

The new two-day ActiNav Basic Training has been designed with a fully practical focus to deliver the best learning experience possible and let users get the most out of it from day 1. By completing the ActiNav Basic Training, trainees become certified ActiNav Core Users, able not only to fully configure, program, and troubleshoot ActiNav stations, but also to decide how ActiNav can bring the highest value to their processes. Download this flyer to learn more.

Check upcoming training dates here or contact ActiNav North America at ActiNavNA@universal-robots.com for more details.

New ActiNav marketing assets

The ActiNav team has generated new marketing assets for our partners, including new animations, images, and brochure. Access and download them here.

Contact

If you have any questions, please contact us at:

- ActiNav team North America: ActiNavNA@universal-robots.com.