Getting your automated CNC setup takes time and effort. Especially when you’re busy trying to get parts out the door. Let us take care of everything for you. Our team rapidly designs, integrates & supports your machine tending setup. Making your automation goals a reality.

Enhanced machine tending

Make the most of your (up)time

Every manufacturer is looking for the same: more output in the shortest time. Yet the current global staffing challenges can significantly hinder it.

That’s most likely why more businesses are exploring alternative solutions to automate the repetitive, heavy-duty machine tending tasks involving CNC, injection molding, press brakes, and stamping brakes.

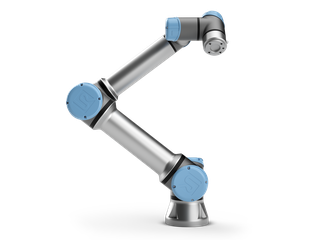

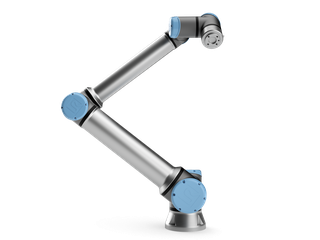

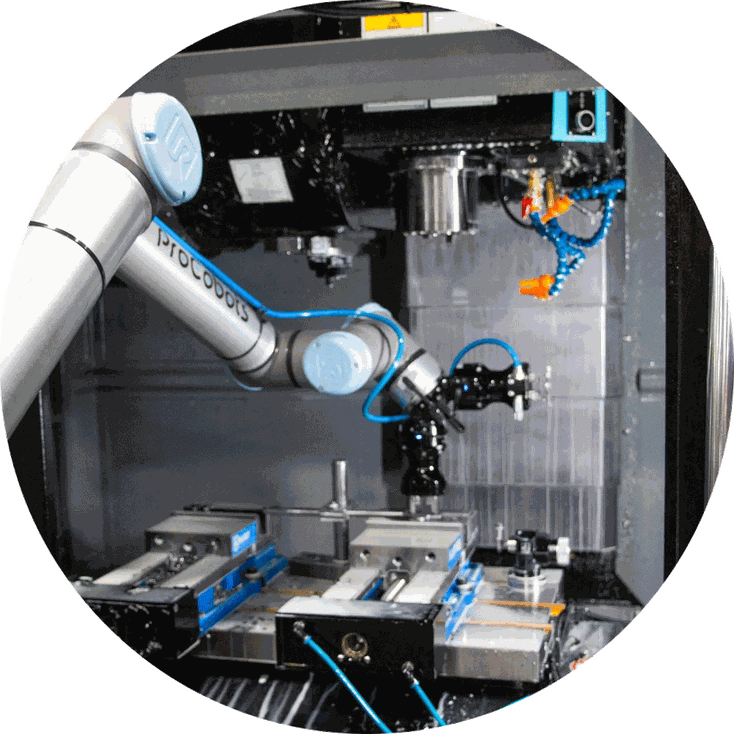

Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, consistent outputs 24/7.

By having operators focus on higher-value tasks that mitigate monotony and the risk of injury, your business can reduce staff turnover while enhancing employee satisfaction.

There are many advantages of using cobots in machine tending

The cobot helped free human labor from simple repetitive tasks, allowing flexible labor re-allocations. As a result, we can control production cost and increase product quality. Thanks to cobots our product failure rate has decreased from 0.03% to 0.01% and production efficiency has increased by 31%.

Y. S. PARK Production Manager, Hyundae Induction Hardening Heat Treatment

Machine Tending Advantages

Turnkey solution for your machine tending needs

From project idea to loading the first lathe, Universal Robots provides you with expert advice and the resources to get your cobot cell running quickly and efficiently.

Within UR's ecosystem of trusted partners, you can find products and services to help you build your machine tending solution. From solution partners and OEMs prepared to create a tailored machine tending solution for your business to the largest showroom of cobot end-effectors, there's an optimal path to answer your machine tending needs.

Let us help you

Let's help you find a solution that fits the resources available and technical skills within your company, and that can efficiently handle the boxes and patterns you need to stack.

Find your Collaborative Robot

Selecting the right collaborative robot for your machine tending solution is a crucial first step to its success. The UR5e, UR10e, and UR20 cobots are commonly used in machine tending applications.

Get your Machine Tending guide

Keep exploring the benefits of automation and learn how businesses from different industries have been using collaborative robots to perform their machine tending tasks.

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI