Universal Robots’ industry-leading collaborative robots will be showcased in more than 30 booths, performing complex tasks that – until now – weren’t considered candidates for collaborative automation

Exhibiting at North America’s largest show for automation technologies, Universal Robots is ready with a cobot cure for a broad new range of complex applications. These provide new opportunities for manufacturers who are plagued by the inability to ramp up production that requires complex TIG or laser welding processes as well as hard-to-staff tasks such as machine tending, dispensing, labeling and screwdriving. “Our application diversity at this year’s Automate speaks volumes,” says Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots (UR). “Attendees visiting us and our partners at the show will have no issue finding a UR cobot automating the task they’re looking for.”

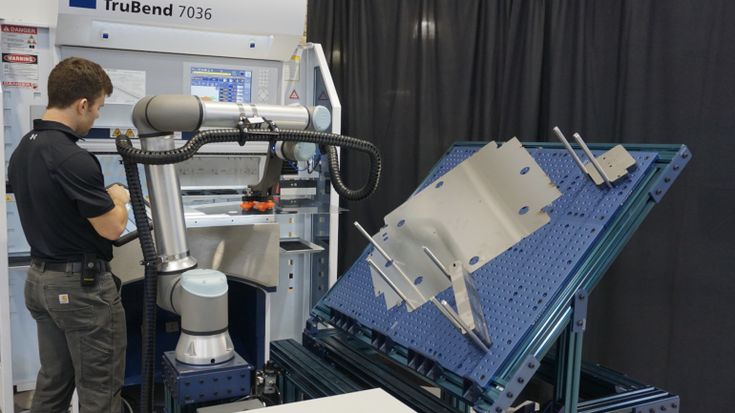

Adding new meaning to the term ‘Universal', the characteristic light-blue jointed collaborative robot arms from UR will be spotted hard at work in more than 30 booths throughout Automate 2022, taking place in Detroit, MI, June 6-9.

Coming out of a record revenue quarter, UR is experiencing broad-based growth from many different segments such as welding, an application area that grew an astounding 300% in 2021 compared to 2020 levels. “Welding is the latest example of an automation frontier now conquered by cobots,” says Campbell. “As we first entered the market, few believed cobots could handle heavy-duty tasks such as welding. Fast forward to this year’s Automate and we have numerous welding applications showcased, reflecting the robust market traction we’re now seeing - not only handling MIG welding but also within more complex processes such as TIG and laser welding.”