Close

Choose your language

使用 UR 協作型機器人,讓螺絲鎖附、插件及組裝等應用更精準而一致

UR協作型機器人手臂可縮短組裝時間,增加生產速度並提高品質

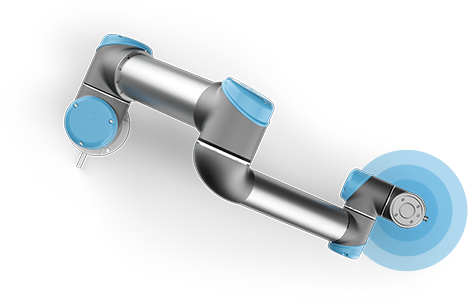

既可精準執行重複性組裝流程,例如鎖附螺絲與螺母、零件安裝以及插入等,又能減少職災發生機率。透過正確的配接機制,UR協作型機器人手臂可組裝塑膠、木頭、金屬或其他材料。人機接觸時,優傲專利技術可確保接觸力道受到限制。此外,UR機器人經編程後,可於人員進入作業區時,自動調整為減速模式,待人員離開後始恢復正常速度。

優傲科技更針對追求生產最佳化的中小企業,打造一座具有前瞻性的平台。每當工作流程改變時,設計輕巧的優傲機械手臂都能快速輕鬆地部署在新產線上。即使毫無經驗,也能透過直覺化軟體快速掌握基本編程技巧。以設定作業路徑點為例,直接手動將機器人移至指定位置即可輕鬆完成。

在鎖附螺絲方面,UR3末端關節的旋轉範圍完全不受限制。e系列機器人內建力矩感應功能,因此可直接與鎖附螺絲應用整合,無須花大錢添購可調整扭力的鎖附螺絲工具。此外,UR機械手臂的重複精度可達+/- 0.03 mm(30微米),對於要求快速精準的鎖附作業來說,絕對是理想的自動化選項。

- 降低運營成本優傲科技讓您盡享先進之機械人自動化的所有優勢,同時,沒有與傳統之機械人程式設定、設置和專用隔離式工作單元有關之任何額外之成本。平均成本回收期 195 天在機械人行業是最快的。

- 現在,您能替代操作人員從事骯髒、危險、單調的工作了,有效減少重複性勞損和意外傷害。成千上萬的 UR 機械人在世界各地與操作者肩並肩工作,(成功通過風險評估後)大部份無需安全防護。

- 透過提高品質、一致性和生產速度,擴大生產能力。機械人手臂可以快速和輕鬆部署至新的流程,您幾乎可以靈活地完成任何手工作業之自動化操作,包括小批量或快速切換之作業。它能就重複的任務重複使用程式。

- UR 機械人可以在大多數裝配場合應用。 可以有效節省空間,且快速重新設定程式,用於不同的機器。機械人擴展可以根據您的製造要求進行定制。

- 優傲科技之所有機械人均認證符合 IP-54 要求。在腐蝕性液體環境中工作時,機械人需要防護。

準備開始使用?

協作機器人具高成本效益、安全,和部署靈活。甚至對於中小企業,協作機器人(亦稱作 cobots)亦可以令自動化變得比以往更為容易。