Material specification of joint lids

Valid from june 2024

New lids kits for e-series and CB3: Lid Kit Pro

The new lid kit is offered as spare parts kits and can be retrofitted onto any eSeries or CB3 robot.

| Item | Part Number |

| UR3 - Lids incl. sealing and increased chemical resistance | 200171 |

| UR3e - Lids incl. sealing and increased chemical resistance | 200137 |

| UR5 - Lids incl. sealing and increased chemical resistance | 200140 |

| UR5e - Lids incl. sealing and increased chemical resistance | 200138 |

| UR10 - Lids incl. sealing and increased chemical resistance | 200139 |

| UR10e/16e - Lids incl. sealing and increased chemical resistance | 200136 |

Material type

PA plastic

Features

New accessory for e-Series and CB3 robots: Lid Kit Pro - increased chemical resistance.

Tested against the following fluids:

- Rocol Ultracut EVO 250 in a 1:20 (4.8%) dilution

- Rems Sanitol (Undiluted)

- Houghton Hocut 4260 in a 1:9 (10%) dilution

- Houghton Hocut 4940

Restrictions for use close to electrostatic discharge (ESD) sensitive devices:

The new lids have been improved to provide more resistance to harsh cutting fluids.

However, the antistatic properties of the material used in these spare part lids do not fulfill our subset of

product requirements, so in case of handling electrostatic discharge (ESD) sensitive devices e.g. in the

electronic industry, we advise not to use these lids in any ESD sensitive application until further notice. Here the original lids fulfill the requirements.

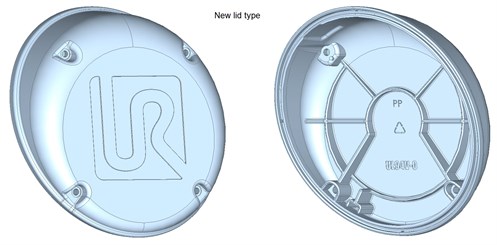

Valid from early q3 2021

Robots produced from the beginning of Q3 2021 has been produced with lids of plast material PC/ASA

Material type

PC/ASA (POLYCARBONATE + ASA) - The lid's inside is coated with aluminum by vacuum metalizing.

Features

Polycarbonate / Acrylonitrile styrene acrylate blends (PC)/ASA offer many of the same benefits other plast materials, but with higher mechanical properties and higher temperature resistance. Key characteristics of PC/ASA are its excellent resistance to weathering and UV degradation, resistance to color fading, retention of properties over time, temperature resistance and excellent mechanical properties.

The materials specification of joint lids below are legacy

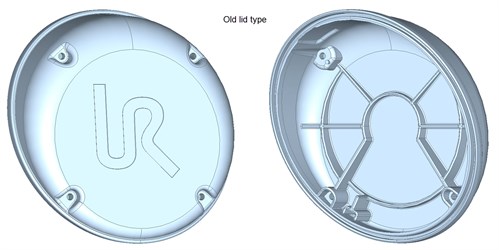

Legacy - from 2013

Valid from

| UR5 | S/N | date | ||

|---|---|---|---|---|

| Size 1 | 201321983x | 16/06/2014 | ||

| Size 3 | 201321983x | 16/06/2014 | ||

| UR10 | S/N | date | ||

|---|---|---|---|---|

| Size 2 | 201320501x | 30/10/2013 | ||

| Size 3 | 201320703x | 30/03/2014 | ||

| Size 4 | 201320501x | 30/10/2013 | ||

All UR3's are manufactures with this type of lid

Material type

PP (Polypropylene)

http://en.wikipedia.org/wiki/Polypropylene

Features

More resistant to cooling liquids and harsh environments

UL94V-0 approved

Square UR logo

LEGACY - from 2009

Valid from

| UR5 | s/n | date | ||

|---|---|---|---|---|

| Size 1 | 200920001x | 01/01/2009 | ||

| Size 3 | 200920001x | 01/01/2009 | ||

| UR10 | s/n | date | ||

|---|---|---|---|---|

| Size 2 | 201220001x | 01/04/2012 | ||

| Size 3 | 201220001x | 01/04/2012 | ||

| Size 4 | 201220001x | 01/04/2012 | ||

Material type

ABS ( Acrylonitrile butadiene styrene)

http://en.wikipedia.org/wiki/Acrylonitrile_butadiene_styrene

Features

Chemicals that can influence ABS plastic: concentrated sulfuric and nitric acids soluble in: esters, ketones, ethylene dichloride and acetone swollen by: glacial acetic acid, carbon tetrachloride and aromatic hydrocarbons. In general esters are very aggressive to ABS plastic, so be careful to use appropriate cooling liquids containing no esters to avoid any damage to the lids.