Empowering tomorrow's workforce

The world is changing faster than ever, and today’s students need to learn completely new set of skills compared to previous generations. Automation is redefining established ways of working in every industry and generating millions of new jobs opportunities along the way. But without professionals specialized in different fields of automation, this new market will remain stuck.

Robotics education program for schools, colleges and universities

The Universal Robots Education Program brings collaborative robotics to life in your classroom, helping students build the skills and experience needed to thrive in the workplaces of tomorrow. Our education kits provide students with direct, hands-on experiences of working with robotics hardware and software, and instructors with a comprehensive curriculum package for easy introduction.

Suitable for a range of education needs, from vocational education at secondary and post-secondary to advanced education & research at universities, the program offers everything your institution needs to provide innovative and immersive robotics courses.

Precision, productivity, and operator empowerment

The cobotic solution implemented by Archytas Robotics, and perfectly integrated with the engraving machine, fully meets the expectations of VCN Industries.

In fact, the company is now completely autonomous at this station, which now produces night-time runs. The solution has significantly reduced marking errors and engraves up to 30,000 parts per month. The result: a productivity gain of around 50%.

Furthermore, since the cobot now supports more than thirty references, operators see their task lightened, which on the one hand has significantly reduced the risks of MSDs, and on the other hand now allows them to focus on operations with higher added value.

Over time, the solution will be able to mark more series of parts to gradually free the operator from this tedious task. Recently, Archytas Robotics integrated a Keyence camera into the device, which allows 100% dimensional control before marking.

Cost-Effective Automation: Enova Robotics Delivers Scalable Cobotic Solution to Transform Denim Spraying at Sartex

Ten times less expensive than automation solutions previously available on the market, the solution developed by Enova Robotics, based on UR5 and UR10 cobots, was designed to meet the brands' CSR requirements and reduce the workload and risks to which the operator was exposed. Enova Robotics guided Sartex through every step of the process, from application design to integration, all accompanied by training.

Originally, the operator held a sprayer in one hand and applied the product to jeans, one by one, which were hung on a carousel. A physically demanding manual operation that kept him busy all day.

An automated and optimized workstation

The automated workstation consists of an automated carousel in front of which are installed a pair of UR5 or UR10 cobots. These are equipped with an electric gun that will be used to spray potassium permanganate onto the jeans - in the desired locations - that circulate in front of them. The UR10s are intended to bleach larger jeans while the UR5s handle the other series.

The automated spraying process operates in a synchronized manner, with two cobots per carousel. The carousel system, also automated by Enova Robotics, allows the user to move on to another pair of jeans once the spraying process is complete. The process is then repeated on the next pair. Among the constraints, Enova Robotics had to successfully adapt the existing sprayer to work with the cobots. Once this initial challenge was overcome, the challenge was to be able to teach the cobot the gesture so that it could reproduce it with the same precision as the operator and with consistent repeatability.

An ultra-personalized learning and programming solution

Indeed, to ensure that the spraying is carried out correctly according to the desired pattern as well as the jeans model, Enova Robotics has developed specific programming software for Sartex. This solution is controlled via a computer or tablet on site, based on the file sent by the company's internal design office.

With over 20 years of experience, the carousel manager uses a sensor-equipped learning sprayer to reproduce the desired patterns for each series of jeans. The software then digitizes the sprayer's movements and converts them into a program that can be executed by the cobot. It then checks whether the cobot is correctly executing the gesture it has learned. These programs are then saved as a library that is easily accessible to operators on the line's control interface.

All you then have to do is choose the series to print from the library, or scan a QR code on the jeans' label - which corresponds to the series - and the robot will repeat the gesture made by the carousel manager.

Thanks to a toolbox included in the program, the jet's trajectory will be adapted to the size of the jeans. The software solution proposed by Enova Robotics is therefore ultra-personalized.

Our education program brochure

Do you want to know more you can download the Education program brochure right here

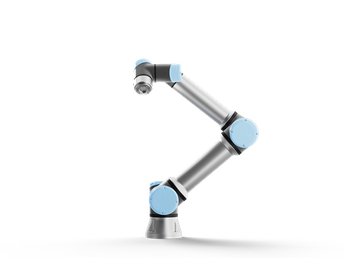

Choose the right collaborative robot for your applications

A range of Universal Robots models are available to address automation needs from precision tasks to long reach and high payload requirements.

Why Universal Robots?

Tried. Tested. Trusted.

Universal Robots has deployed over 100,000 cobots into every manufacturing industry. Companies of all sizes, from Fortune 500 giants to local contract machine shops, are leveraging our 6th generation cobots to increase productivity and quality and improve job satisfaction for their manufacturing teams.

Flexible

UR cobots meet the demands for flexibility head-on with industry-leading ease-of-use, intuitive programming, and a powerful back-end for OEMs and developers to add value and meet specific needs. UR cobot-based systems generate ROI that is usually measured in months, not years.

Worker-safe, worker-friendly

Universal Robots has developed the most complete set of safety tools and functions in the industry. Our safety protocols can be configured to meet the varied safety requirements of your plant or facilities and your application risk assessment, letting your manufacturing team work safely side-by-side with UR cobots.

Get your education kit

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI