2. ROBOTS REPLACE JOBS

For a long time now, the message within manufacturing has been that robots steal jobs. Quite the opposite is true. Robots actually relieve workers from strenuous and repetitive tasks so that they can take on better, more exciting roles within the company. And, with the robots helping to increase productivity, companies often find themselves in a position to hire more people, thus creating jobs, not eliminating them.

A company that experienced this first-hand is Trelleborg Sealing Solutions in Denmark. It needed a single way to optimize production for orders – from one unit to several million. Customers were demanding lower prices, higher quality, and faster delivery, and the global competition was gaining on them in market share. The company was faced with the constant demand for increased efficiency on all fronts. To accomplish its many goals, Trelleborg sought out Universal Robots. With UR’s flexible, lightweight robot, Trelleborg has a useful tool to optimize everywhere within its production. In just two short years the company went from zero to 42 robots and hired 50 extra employees to manage it all.

Notes Jesper Riis, head of the production, “Universal Robots has made a huge difference in our production line. Now we can produce at a much more competitive price than ever before.”

Only 10 percent of jobs are fully automatable, and with cobots the production rises 50% – without job losses. From 2017-2020, robots will create upwards of 2 million jobs globally, but no machine will ever replace human dexterity, critical thinking, decision-making, and creativity.

3. IT’S A HASSLE TO IMPLEMENT AND MAINTAIN ROBOTS

It’s true that there are some robots that are large, cumbersome and difficult to operate. One might say they practically require a Ph.D. to run them. But not cobots. Cobots are easy to implement, operate and maintain. And, because they’re so compact and lightweight, there is no need to change the production layout when switching the cobot between tasks. They’re easily programmed or re-deployed and require minimal maintenance.

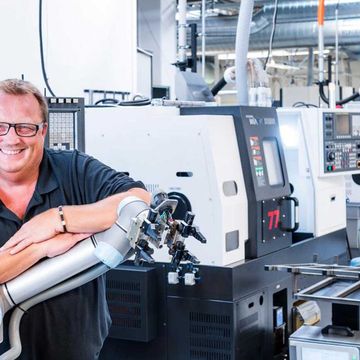

At RSS Manufacturing and Phylrich in California, a short-run production company, it only took 45 minutes to set up and program the Universal Robots unit to perform simple tasks. Deploying a UR5 robot for its machine tending increased production speed significantly while opening up 30% more capacity on existing machinery, enabling RSS Manufacturing to compete with overseas manufacturers.

RSS required flexible automation solutions – robots have to be moved and programmed quickly and taken from machine to machine. With Universal Robots, set up time between jobs is now only around 30 minutes, which greatly impacts overall efficiency. “If you can write a to do list, you can program the robot,” said Shane Strange, automation and integration specialist with RSS. “The most beneficial part of the robot is the interface control so you can be right there next to it and troubleshoot as you go. You can do your programming from a handheld device. The convenience is unbeatable.”