世界變化比以往任何時候都快,與前幾代人相比,今天的學生需要學習一套全新的技能。自動化正在重新定義每個行業的既定工作方式,並在此過程中創造數百萬個新的就業機會。但是,如果沒有專門從事不同自動化領域的專業人員,這個新市場將繼續停滯不前。

賦予未來的勞動力權力

Precision, productivity, and operator empowerment

The cobotic solution implemented by Archytas Robotics, and perfectly integrated with the engraving machine, fully meets the expectations of VCN Industries.

In fact, the company is now completely autonomous at this station, which now produces night-time runs. The solution has significantly reduced marking errors and engraves up to 30,000 parts per month. The result: a productivity gain of around 50%.

Furthermore, since the cobot now supports more than thirty references, operators see their task lightened, which on the one hand has significantly reduced the risks of MSDs, and on the other hand now allows them to focus on operations with higher added value.

Over time, the solution will be able to mark more series of parts to gradually free the operator from this tedious task. Recently, Archytas Robotics integrated a Keyence camera into the device, which allows 100% dimensional control before marking.

Cost-Effective Automation: Enova Robotics Delivers Scalable Cobotic Solution to Transform Denim Spraying at Sartex

Ten times less expensive than automation solutions previously available on the market, the solution developed by Enova Robotics, based on UR5 and UR10 cobots, was designed to meet the brands' CSR requirements and reduce the workload and risks to which the operator was exposed. Enova Robotics guided Sartex through every step of the process, from application design to integration, all accompanied by training.

Originally, the operator held a sprayer in one hand and applied the product to jeans, one by one, which were hung on a carousel. A physically demanding manual operation that kept him busy all day.

An automated and optimized workstation

The automated workstation consists of an automated carousel in front of which are installed a pair of UR5 or UR10 cobots. These are equipped with an electric gun that will be used to spray potassium permanganate onto the jeans - in the desired locations - that circulate in front of them. The UR10s are intended to bleach larger jeans while the UR5s handle the other series.

The automated spraying process operates in a synchronized manner, with two cobots per carousel. The carousel system, also automated by Enova Robotics, allows the user to move on to another pair of jeans once the spraying process is complete. The process is then repeated on the next pair. Among the constraints, Enova Robotics had to successfully adapt the existing sprayer to work with the cobots. Once this initial challenge was overcome, the challenge was to be able to teach the cobot the gesture so that it could reproduce it with the same precision as the operator and with consistent repeatability.

An ultra-personalized learning and programming solution

Indeed, to ensure that the spraying is carried out correctly according to the desired pattern as well as the jeans model, Enova Robotics has developed specific programming software for Sartex. This solution is controlled via a computer or tablet on site, based on the file sent by the company's internal design office.

With over 20 years of experience, the carousel manager uses a sensor-equipped learning sprayer to reproduce the desired patterns for each series of jeans. The software then digitizes the sprayer's movements and converts them into a program that can be executed by the cobot. It then checks whether the cobot is correctly executing the gesture it has learned. These programs are then saved as a library that is easily accessible to operators on the line's control interface.

All you then have to do is choose the series to print from the library, or scan a QR code on the jeans' label - which corresponds to the series - and the robot will repeat the gesture made by the carousel manager.

Thanks to a toolbox included in the program, the jet's trajectory will be adapted to the size of the jeans. The software solution proposed by Enova Robotics is therefore ultra-personalized.

我們的教育專案手冊

想瞭解更多資訊嗎?您可以在此處下載教育計劃手冊

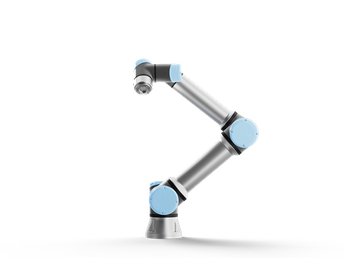

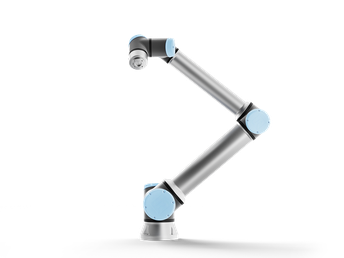

為您的應用選擇合適的協作機器人

一系列Universal Robots模型可用於滿足自動化需求,從精確任務到長距離和高有效載荷要求。

為何選擇Universal Robots ?

經過嘗試。經過測試。值得信賴。

Universal Robots已在每個製造業中部署了超過100,000個cobots。從財富500強巨頭到當地合約機商店,各種規模的公司都在利用我們的第六代cobots來提高生產力和質量,並提高其製造團隊的工作滿意度。

彈性

UR cobots透過業界領先的易用性、直觀的程式設計,以及OEM和開發人員增值和滿足特定需求的強大後端,正面滿足對靈活性的需求。以UR合作機器人為基礎的系統所產生的投資報酬率通常以月為單位,而非以年為單位。

勞工安全、勞工友善

Universal Robots開發了業界最完整的一套安全工具和功能。我們的安全協議可以配置為滿足您工廠或設施的各種安全要求以及您的應用風險評估,讓您的製造團隊與UR cobots一起安全地工作。

取得教育套件

- 丹麥商優傲科技股份有限公司台灣分公司

- 內湖區瑞光路360號4樓

- - 台北市