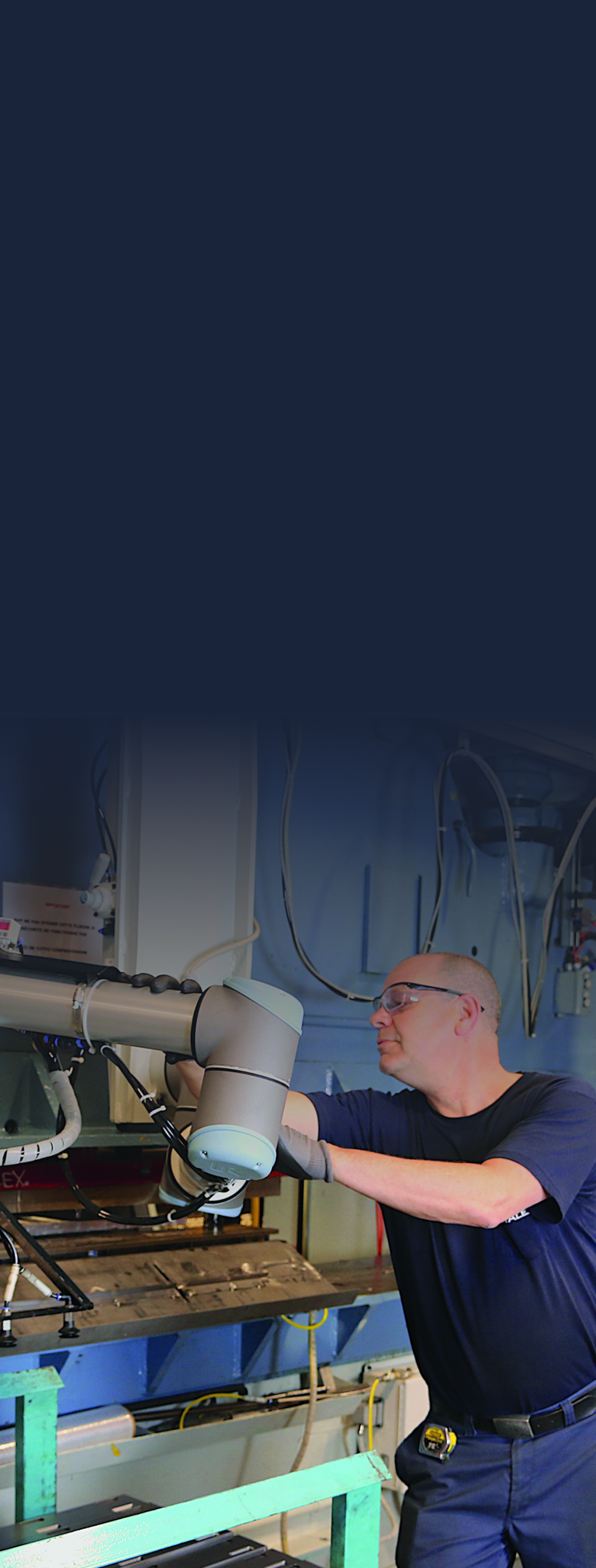

Plant Engineer with Etalex, Jean Francois Rousseau, was eager to try out this new type of robot:

“We needed a flexible automation solution that could be used for 10 different production cycles. Since I only have 6 feet of space in front of the brake press, it was important that I could run this application without safety caging around it.” Before the arrival of Etalex’ new robot colleague, an employee would manually unload the press brake 8 hours a day. The manual tasks have now been reduced to an hour daily spent on inspecting the quality of each pallet and changing the coils, resulting in an estimated ROI of about 12 months.