Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

Beijing BAI Lear Automotive System Co., Ltd. (BAI Lear) is a joint-venture established by Beijing Hainachuan Automotive Parts Co., Ltd. (BHAP) and Lear Corporation committed to the design and manufacturing of car seat systems. The company now has over 800 employees serving a number of renowned clients like Beijing Benz and BAIC BJEV with annual sales up to RMB 3 billion.

By virtue of the expertise of its American parent company Lear Corporation, BAI Lear aims to establish a leading position in China’s automotive seating market. Ranking #148 on the Fortune 500 list in 2018, Lear Corporation boasts the most comprehensive technologies and processes in the automotive seating field and is well-known for supplying superior and economic seating products ranging from mass-produced systems and special-purpose seat solutions, which are widely used in various vehicles such as small RVs, SUVs and full-size cars.

With the rapid development of auto market in China, BAI Lear has seen its capacity steadily expanding in recent years. On average, BAI Lear produces 1,500 sets of seats (each including two seats for driver and co-driver) and tightens 6,000 screws a day. When deploying the automation solution, a long delay is unacceptable in production and the period of adaption between workers and new equipment needs to be shortened. Therefore, Lear urgently needs to introduce an efficient and flexible automation solution.

Since the first UR10 cooperative robot for screw tightening was launched on October 7, 2017, Lear has deployed 38 UR cooperative robots in China, mainly used for car seat screw tightening, electrical inspection, parts picking and placing, as well as other processes.

As the world's largest and fastest-growing automotive market, China is strategic market that all car manufacturers compete for. Though in 2018, the Chinese auto market experienced the first negative growth for the past 28 years, with annual sales dropping to 28 million vehicles, the industry still holds an opinion that it's a short period of adjustment before entering a more mature stage. In this period, car manufacturers need to increase its competitiveness in terms of quality and price so as to grasp the opportunities arising in industrial restructuring.

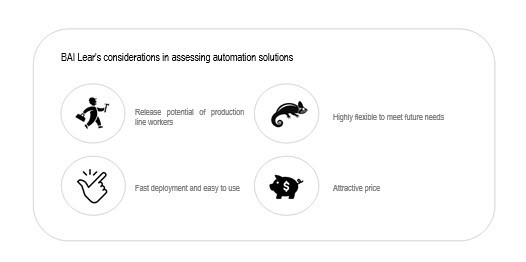

BAI Lear's management begun considering about production optimization and upgrade several years ago in order to promote sustainable development and adapt to the market changes in the long run. In this respect, industrial automation is a feasible way. In assessing automation solutions, the company mainly focuses on the following four aspects:

Release potential of production line workers- There are many processes in car seat production that are extremely important, but repetitive and boring, such as tightening screws on the seat. After a period of time, employees may tend to quit the job and thus lead to a high staff turnover rate, which will further affect the overall productivity. Therefore, such processes are the ideal targets for automation transformation.

Quick to deploy and easy to use -With the rapid development of auto market in China, BAI Lear has seen its capacity expanding in recent years. On average, BAI Lear produces 1,500 sets of seats (each including two seats for driver and co-driver) and tightens 6,000 screws a day. When deploying the automation solution, a long delay is unacceptable in production and the period of adaption between workers and new equipment needs to be shortened.

Highly flexible to meet future needs- Facing an increasingly competitive auto market, car manufacturers need to attract consumers with new vehicles and improved parts. Therefore, the manufacturers of the downstream supply chain, including car seat manufacturers, are required to demonstrate high adaptability, and timely adjust production to meet changes of product specification.

Attractive price- BAI Lear places high emphasis on the total cost of ownership (TCO) of the automation solution; cost factors considered include price of product and accessories, time investment for user training, maintenance services, and footprint in the workshop.

In the early stage of the assessment, BAI Lear deemed industrial robots as a feasible solution, but after further considerations, given the limited space for installation in the workshops, the high cost of traditional industrial robots and the low flexibility to adapt to future needs, BAI Lear was then convinced that cobot (collaborative robot) can better meet its needs.

After comparison and assessment to a variety of cobots available in the market, BAI Lear finally determined that UR is the ideal choice. UR's cobots can meet users' needs of automation well and is meanwhile economical and cost-efficient in comprehensive use. In addition, it features simple configuration, reliable operation, and user-friendly experience, thus greatly shortening the integration and commissioning cycle, and reducing the project risks.

Joint Cooperation to Achieve win-win in User Channel

From the original idea of introducing cobots to the implementation of the final scheme, a reliable partner is indispensable to its success. SiguVI plays an important role of bridging different parties in the entire project. In the initial cooperation, SiguVI and UR had together formulated the preliminary scheme for BAI Lear.

Mr. Song Xiaohui, GM of BAI LearAs a manufacturing enterprise, we've been receiving higher requirements from our clients every year, so we have to constantly enhance our production process control, and guarantee stable productivity and improve conformity of production. The introduction of cobots meets the above requirements while improving the factory production and personnel flexibilit

In 2017, BAI Lear decided to deploy UR10 robots, mainly used for car seat screw tightening, electrical inspection, parts picking and placing, as well as other processes.

The UR10 six-joint robot adopts modular design, each joint's articulation range being +-360 degrees; the robot arm weights only 28.9 kg, effective load 10 kg, working range 1300 mm, installation size only 190 mm of diameter range; maximum tool-side operating speed 1m/s, re-positioning accuracy +-0.03 mm; robot I/O signals including digital and analog signals, Ethernet communication that meets the TCP/IP MODBUS protocol; 12-inch touch-screen for demonstrator, PolyScope GUI installed; 220VAC power for the robot control box, typical program consuming only 350W power; ambient temperature for robot operation ranges from 0°-50°.

UR10 features easy programming, fast installation and setup, flexible re-deployment, human-machine collaboration and safety; the robot arm can be reversely driven to be directly pulled for programmed demonstration; by setting security parameters, and upon safety assessment, UR10 can meet human-machine collaboration needs without installing the security fence.

UR10, as a lightweight, small, and human-machine cooperative robot, is especially suitable for assembly, machine tool feeding and blanking, material testing, pick-and-place of articles, stacking and unstacking, grinding and polishing in such industries as electronics, home appliances and 3C.

BAI Lear's adoption of UR robots has achieved immediate results, and fully meets all requirements for industrial automation as above-mentioned.

Fast Deployment Approaching "Turnkey Solution" Speed

After the signing of the purchase agreement, UR immediately arranged robot delivery, installation, and user training for BAI Lear. The first UR10 collaborative robot for screw tightening has been operating since it was launched on October 7, 2017.

An engineer from BAI Lear said: "I had no previous programming experience, but UR's patented technology allowed me to quickly set up and operate the cobot; it took me only a few minutes to learn how to start and stop the machine, and even write a program. And I found it quite interesting to work with the robots. They totally follow my commands. So my work strength and pressure is greatly decreased, and I feel much easier.

Production Stability and Efficiency Improved Significantly

UR robots are mainly used for car seat screwing, electric testing, accessory pick-and-place, and other processes. With the adoption of collaborative robots, BAI Lear has improved the consistency of product quality and reduced possible human errors, thus enhancing customer satisfaction.

Benefit Employees From Automation

After the introduction of UR robots, the workers who were originally responsible for these production lines could turn to perform more value-added tasks. Robot technology development plays an important role in supporting intelligent manufacturing, productivity lifting, innovation enhancement, and core competitiveness promotion.

Higher Productivity with Guaranteed Safety Production

Mr. Song Xiaohui, GM of BAI Lear, said: "As the UR cobots were being deployed, it lowered the threshold for us to achieve automation, so that the users, namely the colleagues of the company, gain many benefits, such as no security fencing, simple programming, flexible installation and deployment, and space saving."

Mr. Song said: "As a manufacturing enterprise, we've been receiving higher requirements from our clients every year, so we have to constantly enhance our production process control, and guarantee stable productivity and improve conformity of production. The introduction of cobots meets the above requirements while improving the factory production and personnel flexibility. BAI Lear is also considering introducing more UR robots or applying them to more processes.”

Mr. Su Bikai, GM of UR China, said: "We feel so honored that UR cobots could get involved in BAI Lear's transformation and upgrading to automated production. We, as a leading enterprise in the cobot area, will continue to commit ourselves to helping those with future vision to achieve innovative collaboration, and to building a general application ecosystem.

Thousands of businesses rely on Collaborative Robots to...