Robotic welding is a process that helps the industrial sector to automate its processes, increase accuracy, enhance safety and reduce lead time. The robot welding process is considered to be the most productive when it is implemented for high-volume and repetitive tasks. There are multiple types of robotic welding processes. In this article, we will go through each of them in detail and understand their benefits and applications. Read on to learn more!

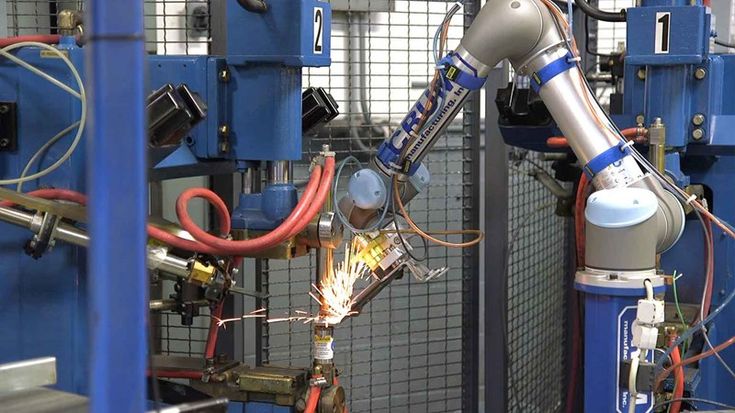

When a welding process is automated using robots, we call it robotic welding. These building robots perform and manage welding tasks based on the program and are capable of being reprogrammed as per the intended project. However, this does not eliminate human intervention as welders still control and supervise the welding robots.

Welding robots bring many benefits to the manufacturing process, including precise results, less wastage, and improved safety. These robots can reach locations that are inaccessible by human hands and perform complicated tasks much more precisely. Therefore, the time taken in the manufacturing process is minimised and greater flexibility is achieved.

There are different types of robotic welding available on the market, and the main focus should be on choosing the correct welding program for a long-lasting and durable impact. Through this article, we hope you will be able to understand the entire process better for informed decision-making.