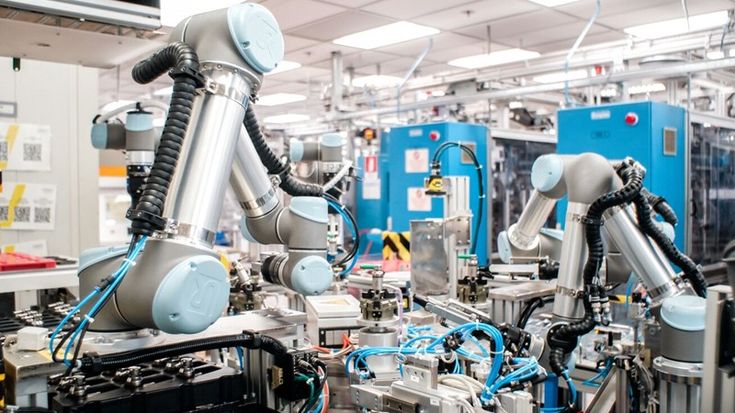

Businesses are nowadays leveraging industrial robotic arms to keep up with the competition and minimise their costs to facilitate automation of key processes. Robotic arms enhance the safety of workers, accelerate production, and improve overall productivity. In this article, we will brief you on what exactly a robotic arm is and how it works. Additionally, we will also take you through the different types of industrial robotic arms and their roleplays. So keep reading!!

Robotic Arm

What Is a Robotic Arm?

Robotic arms are devices that have been designed to do a given activity or job swiftly, correctly, and effectively. They're usually motor-driven consisting of a collection of joints, articulations, and manipulators, and are employed to accomplish heavy and/or repetitive processes quickly and consistently. They are particularly valuable in the industries of industrial production, manufacturing, machining, and assembly.

When programming and using them, there is an urgent need to be highly cautious as they greatly boost production speeds and precision of placement. However, this isn't the case with the cobot arms provided by Universal Robots as they have a good risk assessment. As technology has progressed and the cost of manufacturing robotic components has decreased over time, the availability and affordability of robots and mechanical arms have exploded across a wide range of sectors in the last decade or so.

A Brief History Of Robotic Arms

In 1495, Da Vinci designed the world's first advanced robotic arm, with four degrees of freedom and an analogue onboard controller that provided power and programmability.

In the 18th century, Von Kemplen's left arm was a clever chess-playing robot.

In 1961, Unimate created the first industrial robotic arm, which later evolved into the PUMA arm. The Rancho arm was created in 1963, while Minsky's Tentacle arm debuted in 1968, Scheinman's Stanford arm debuted in 1969, and MIT's Silver arm debuted in 1974. In 1993, Aird became the first cyborg person to have a robotic arm.

Miguel Nicolalis' work on brain implantation in owl monkeys directly interacting with mechanical arms both locally and at a distance in 2000 expanded conceivable man-machine capability. And since then, the entire manufacturing process of robot arms has only developed and grown.

What Is Meant By Robotic Arm Design?

In industries and labs, robotic arms are commonly employed. Like other robots, robotic arms have several distinct components that all work together to ensure that they perform effectively.

Controllers

The controllers are the robotic arms' main processors and operate as their brains. They can be set to behave automatically, or they can be manually operated by receiving instructions from a specialist. They are the control consoles for mechanical arms, and they come in several forms depending on the amount of computing power required.

Arms

The arm, which is made up of three major parts: the shoulder, elbow, and wrist, is the major portion of the robotic arm. The shoulder, which rests at the base of the arm and is normally attached to the controller, can move forward, backward, or spin. The elbow is located in the centre of the arm, allowing the upper part to move forward and backwards independently of the bottom section. Finally, the wrist connects to the end effector at the very end of the upper arm.

End Effector

The end effector serves as the robotic arm's hand. It usually has two claws, but it can also have three, which can open and close on demand. It may also be spun on the wrist, making it simple to move materials and equipment.

Drives

Drives are the motors that regulate the movement and manoeuvring between the joints. Some models employ belts that are comparable to those seen in automobile engines.

Sensors

Advanced robots are more likely to have sensors. Some are equipped with sensors that allow them to detect and respond to their surroundings. They can, for example, avoid accidents between two robots operating nearby (using a very complex AI) or enable a robot to modify its hold on a delicate object to avoid injuring it (depending on the attached end-effector).

Understanding The Working Of The Robotic Arm: How Does The Robotic Arm Work?

In manufacturing, the robotic arm is commonly employed. Seven metal pieces linked by six joints make up a standard mechanical arm. Individual stepper motors linked to each joint are rotated by the robot's control computer (some larger arms use hydraulics or pneumatics). Step motors move in precise increments, unlike regular motors. By repeatedly executing the identical motion, the computer can manipulate the arm very accurately. The robot uses motion sensors to ensure that it moves just enough.

An industrial collaborative robot with six joints, which includes the equivalent of a shoulder, elbow, and wrist, closely mimics a human arm. Instead of being mounted on a moving body, the shoulder is often attached to a fixed base structure. With six degrees of freedom, this kind of robot can pivot in six distinct directions. In contrast, a human arm has seven degrees of freedom.

Your arm's function is to move your hand from one location to another. Similar to this, the function of the robotic arm is to move an end effector. Robotic arms may be fitted with a variety of end effectors, each of which is appropriate for a certain purpose. A simplified hand that can grip and carry various things is one frequent end effector.

Some models of robotic hands frequently contain in-built pressure sensors that communicate to the computer how firmly the robot is holding an object. This prevents the robot from dropping or shattering the object it is holding.

The 6 Different Types of Robotic Arms

There are many different varieties of robotic arms on the market today, and each is built with essential core capabilities and tasks that make certain particular models particularly suitable for particular professions or industrial settings. Most of the time, the primary differences between various types of mechanical arms are found in the joints' ability to articulate the type of framework they are supported by, and the installation and operational footprint they require.

Cartesian Robot/Gantry Robot

Cartesian robot arms are called after the Cartesian coordinate system and are frequently referred to as rectilinear or gantry robot arms. In essence, the widely used system of X, Y, and (less often) Z axes that we nearly always see represented on any normal graph is a result of cartesian coordinates.

Mechatronic Cartesian or gantry robots are robotic arms that typically include three articulating joints. These joints may be programmed to move linearly in three dimensions along these three axes using the X, Y, and Z coordinates. Additional rotational capability is frequently provided by the wrist joint.

Cartesian robotic arms operate a tool or attachment through linear motions to change locations in three dimensions. They do this by using a variety of motors and linear actuators. They are frequently employed for various purposes, including selecting and placing items next to conveyor belts and machining components. They can be installed horizontally, vertically, or above.

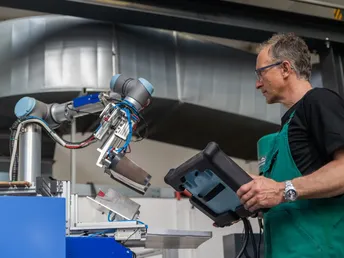

Collaborative Robot/Cobot

In a shared, collaborative workspace, collaborative robots are a type of robotic automation designed to function securely alongside human employees. In most cases, a collaborative robot is in charge of tedious, repetitive duties while a human employee handles trickier, more mentally taxing jobs. Collaborative robots' precision, dependability, and repetition are intended to supplement a human worker's intelligence and problem-solving abilities.

The designs of collaborative robots are very different from those of industrial robots. Collaborative robots are primarily made for safety, which is why they have rounded edges, force limits, and a lower payload. The majority of collaborative robots have several sensors to prevent accidents with human employees and safety processes to shut down if any kind of unforeseen interaction takes place.

Cylindrical Robot

Contrary to the Cartesian versions described above, cylindrical robot arms have axes that constitute a cylindrical coordinate system; in other words, their preprogrammed movements occur within a cylinder-shaped environment (up, down, and around). The rotary and prismatic joints on this sort of arm allow it to move both linearly and rotatorily during assembly operations, spot welding, and machine tool handling.

Spherical Robot/Polar Robot

A polar or spherical robot functions inside a spherical "work envelope" or possible locus of movement, much like the cylindrical robotic arms mentioned above. A combined rotational joint, two rotary joints, and a linear joint are used to accomplish this.

The polar robotic arm has a twisting joint that connects it to its base, and because of the spherical workspace it has access to, it can carry out tasks that cylindrical robotic arms cannot, including operating machine tools and conducting spot welding, die casting, and arc welding.

SCARA Robot

The most common uses for SCARA robot arms are assembly and pick-and-place tasks. The name SCARA, which stands for "Selective Compliance Assembly Robot Arm," refers to their capacity to maintain rigidity along particular axes while tolerating a small amount of "compliance" (flexibility, in the context of robotics).

Due to their selective compliance capabilities, SCARA robotic arms—possibly the type you imagine when you picture a high-tech production line—are perfect for these uses. A certain amount of tolerated flexibility in some directions but not others is particularly beneficial for some assembly and placement activities because it enables the insertion of components into tight places without binding or harming any of the pieces.

Articulated Robot

The most prevalent kind of industrial robot is the articulating one. Perhaps one of the reasons they stick out so strongly in our brains is because of how much they resemble human arms. The true cause of its pervasiveness and endurance, however, lies in the mechanical advantages of this design. The advantages of precise movement are combined with a wide range of rotating motion and linear reach in the arm design.

For welding, material handling, pick-and-place tasks, and dispensing, articulated arms are perfect. There is essentially no place in their work envelope that they cannot reach because of their multiple axes and degrees of freedom. As a result, articulated robots are among the most adaptable, flexible, and space-saving designs available. It's crucial to keep in mind that articulated robots are by nature dangerous. It may be more dangerous for operators to install an articulated robot in a situation where there is no risk mitigation. To reduce the risk of injury to human operators, articulating robots must be equipped with the necessary safety features.

4 Advantages of Robotic Arms: Why Use Robot Arms to Automate Your Business Processes?

Industrial robotic arms can provide several advantages to businesses:

Improved Safety

Robotic arms keep employees safe by functioning in hazardous areas and doing jobs that pose a high risk of human injury.

Better Productivity

Robotic arms can work nonstop for 24 hours a day, seven days a week, helping organisations enhance output by keeping production, inspections, and other operations running continually.

Better Precision

Robotic arms, by their very nature, are more constant and precise than humans when it comes to jobs that need exceptional accuracy or consistency.

Improved Flexibility

Robotic arms may readily be repurposed for new operations or installed on alternative platforms, such as autonomous mobile robots (AMRs), a fixed assembly line platform, or a wall or shelf, when business objectives change.

The Rise of Robotic Arms in Manufacturing: Why Are Industrial Robotic Arms Used in Manufacturing?

Industrial robotic arms are used in production for several purposes. They are used and positioned in regions:

- Where it is necessary to reduce threats to humans

- When greater strength or precision is required than a person

- When the task is too monotonous for human employees

- When the continuous operation is needed

Robots are a highly sought-after item in the industrial industry since many of them can repeat actions and motions with a precision of a few thousandths of an inch and are available 24 hours a day. The precision of a robotic arm depends on calibrating and maintaining the machinery.

Medical device manufacturing is an example of a sector that makes extensive use of mechanical arms. Due to their ability to make precise and accurate laser incisions during surgical operations, robotic arms have particular appeal to the medical industry. Additionally, they are employed in the manufacturing of vials and medicines, assisting in the removal of flaws such as the possibility of human contamination. Automation increases productivity and reduces mistakes, which is why it is increasingly in demand across many different sectors.

The positive effects of industrial robotic arms on production are still expanding as newer robots with improved specifications are released. We could be living in a time when industrial robotic labour is the standard in all factories that produce goods.

4 Real World Applications of Robotic Arms

One of the most important features of industrial robotic arms is their ability to accommodate a wide range of applications. Automating these operations not only eliminates human errors but also frees up personnel to focus on higher-value jobs such as client interaction. Here are a few examples of how manufacturers are now employing robotic arms:

Palletizing

The process of loading items or products onto pallets can be automated by robotic arms. Palletizing becomes more precise, cost-effective, and predictable when the process is automated. Human employees are also freed from duties that pose a danger of bodily damage thanks to the use of robotic arms.

Material Handling

Material-handling robotic arms can aid in the creation of a secure and efficient warehouse by ensuring that items and materials are appropriately kept, accessible, and moved. These operations may be automated to assist in speeding up the delivery of items to clients, avoid workplace accidents, and increase a facility's efficiency.

Inspection

A quality inspection is usually performed towards the end of a production line, delaying the identification of production quality concerns. Today, businesses are targeting the use of robots to earn profits by performing real-time inspections using vision and AI systems and reducing waste and downtime.

Pick and Place

In contemporary production and logistics, pick-and-place robots are commonly used. They have powerful machine vision systems that can rapidly and efficiently recognise an object, grip it, and transport it from one point to another, increasing the pace of manufacturing and distribution of commodities.

Customer Stories

2D&S s.r.o.

Unilever Poland

Conclusion

Robot arms are appropriate for activities that are repetitive, consistent, and need a high level of accuracy, as well as for tasks that a human worker could find difficult to complete safely. Robotic arms are quick, precise, and dependable, and they can be programmed to execute an almost limitless number of tasks.

Industrial robotic arms have become significantly more widely used than ever before because of huge reductions in buy-in prices over the last decade. We hope through this article that all your doubts regarding robotic arms are cleared. Go ahead and invest in a robotic arm to achieve economies of scale in your business. Talk to a member of our team about how you can implement them into your production lines today.

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI