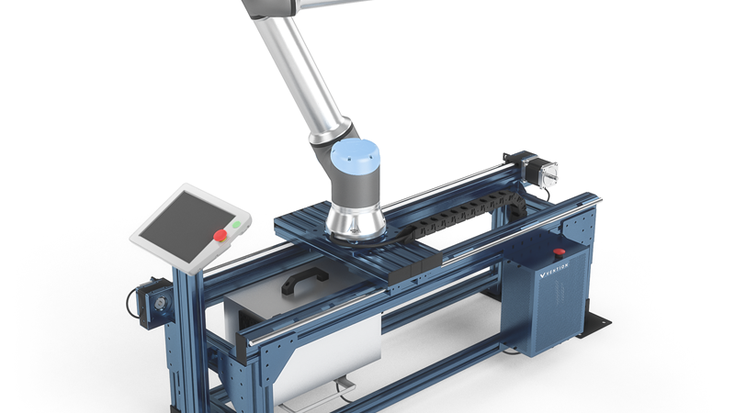

Vention's 7th axis range extender - fits all three UR cobot models.

The FABTECH show displays not only how capabilities of UR cobots widen with UR+ enabled tools, the physical reach of the robot arms are now improved through Vention's new 7th axis range extender designed for all three UR models, soon to be featured in the UR+ showroom too. “We’re proud to contribute to the UR+ ecosystem with rapid design and commissioning of robot cells,” says Patrick Halde, Vice President of Sales and Business Development with Vention. “Our new 7^th^ axis solution can be controlled with Vention’s MachineMotion controller directly through the UR cobot’s touch screen allowing users to assemble and self-commission in hours.”

Universal Robots’ Regional Sales Director for Americas, Stuart Shepherd, looks forward to showing the FABTECH audience the capabilities and applications now enabled with the new UR+ solutions. “It’s exciting to see our partner network embracing our new e-Series cobots, incorporating them into cutting edge applications so quickly,” he says. “We’re confident the metal fabricating industry will deploy a significant number of e-Series cobots with certified UR+ products in the year to come.”

Universal Robots will also be on display in the following FABTECH booths:

American Weldquip LLC – Booth C11322

UR10e with American Weldquip’s ArcSafe robotic welding torch system collaborative robot featuring the Robo-Quip robotic nozzle cleaning station. American Weldquip chose Universal Robots UR10e because it is only one of the few collaborative robot systems that can be used in welding applications, allowing operators to work alongside the cobots without the need for the usual safety guarding.

ARC Specialties – Booth C13462UR10e integrated with SnapCut end-effector for plasma cutting applications (see above).

ATI Industrial Automation – Booth C11522UR 5 showcased with ATI’s UR+ enabled MC-10 tool changer and Axia80 f/t sensor. Unlike load cells, which only operate on a single axis and measure only push, the Axia80 senses torque and side loads along all six axes.

Crum Manufacturing – Booth C10161Crum Manufacturing will exhibit a UR3 with a Gocator 2330 from LMI Technologies demonstrating the ability to line track, profile scan and measure parts. The use of a laser profile scanner allows the robot to easily determine pick locations on randomized part positions. This also allows for easier part quality control, as the Gocator is able to measure the parts that the robot will be picking.COB Industries/HFT – Booth C10871COB Industries will display a UR3 in Huntingdon Fusion Techniques’ inert welding environment, that have grown very popular with the additive manufacturing industry who utilize the HFT inert environments in conjunction with robots to apply 3D printing techniques with specialty materials such as titanium and tantalum. **** Innerspec – Booth C10523UR3 integrated with TG-IL, Innerspec’s latest generation of EMAT thickness measurement. The UR3 scans a non-contact EMAT UT transducer along the length of an aluminum tube, measuring wall thickness variations to +/-0.0001”. TG-IL is housed in an IP54 industrial enclosure and is ready to be integrated into any industrial environment where automated thickness measurement is required.

Vention – Booth B5655UR10e mounted on Vention's fully customizable 7th axis range extender (see above).