Collaborative robots are a type of industrial robot that can work in the same space as humans. They are used in manufacturing sites and logistics centers across a variety of industries, helping to resolve labor shortages and improve work efficiency. This page provides a detailed explanation of the definition of collaborative robots, how they differ from industrial robots, and

What is a collaborative robot? A thorough explanation of its definition, benefits, and differences from industrial robots

table of contents

What is a collaborative robot?

Collaborative robot definition

The background to the birth of collaborative robots

Collaborative robot market trends

Benefits and challenges of introducing collaborative robots

Benefits of implementation

Implementation challenges

Read the Collaborative Robot Guidebook

Collaborative robot adoption cases

Differences from industrial robots

How to choose a collaborative robot

summary

What is the collaborative robots?

Collaborative robot definition

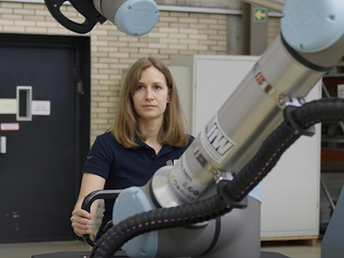

A collaborative robot is a type of industrial robot equipped with a safety function that stops it safely when it comes into contact with an external object such as a person.

The greatest feature of this system is that it can be introduced into the same space as people, without being separated by safety fences, by using robots that comply with the safety requirements set out in safety standards established by the International Organization for Standardization (ISO) and by conducting risk assessments of the system to confirm human safety.

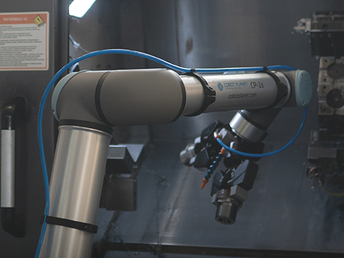

Since Universal Robots first sold collaborative robots in 2008, their adoption has accelerated worldwide, as they are used to automate tasks that traditional industrial robots have given up on automating.

In Japan, the Industrial Safety and Health Regulations (Article 150-4), established in 1983 to prevent industrial accidents, require industrial robots to be enclosed by safety fences and isolated from humans.

The term "industrial robot" was further defined in the Ministry of Labor's Notification No. 51 of the same year as "machines with a drive motor exceeding 80W." This is commonly known as the 80W regulation. Since then, collaboration between industrial robots and humans has been strictly restricted. This regulation reached a turning point in 2013, when a major deregulation was implemented. The Ministry of Health, Labor and Welfare issued Notification No. 1224-2. This now allows industrial robots with an output of 80W or more to be used in collaboration with humans without safety fences, provided they meet the safety requirements set forth in ISO 10218 and ISO/TS 15066 established by the International Organization for Standardization (ISO). Robots that meet these conditions are generally referred to as collaborative robots. The main contents of these standards are as follows:

- (1) Safety-compliant monitoring stops; (2) hand guides; (3) speed and distance monitoring; and (4) power and force limitations due to inherent design or control.

- The safety-related parts of the control systems for these functions must comply with PL=d in a category 3 architecture as specified in ISO 13849-1 or SIL2 as specified in IEC 62061 with a proof test interval of at least 20 years and a hardware fault tolerance of 1.

Universal Robots' collaborative robots have the ability to safely detect and stop force when coming into contact with a person or the outside world, with a reliability of PL=d and Category 3. This satisfies the power and force limitations in condition (4) above, so they can be used in collaborative robot applications.

The background to the birth of collaborative robots

Collaborative robots were developed to address the unmet need of automation, where automation was not possible due to the limitations of conventional automation equipment. Conventional industrial robots have been introduced to reduce costs and improve quality on mass production lines, but they required safety fences to surround the robot and surrounding equipment when installed. This meant that they could not be introduced where space was limited or where human intervention was required for handling a wide variety of products or for setup changes.

Technological innovation led to the development of collaborative robots with built-in safety features, and the establishment of ISO safety standards also contributed greatly to their widespread adoption. These were groundbreaking safety standards at the time, prioritizing the inherent safety design of machines and combining the necessary safety protection measures for each system as functional safety, which allowed for contact with humans depending on the level of harm. This made it possible to introduce collaborative robots into the same spaces as humans without safety fences. As a result, collaborative robots have been increasingly introduced in various workplaces around the world, contributing to improved working environments and increased productivity.

Collaborative robot market trends

The collaborative robot market has grown rapidly since the first one was sold in 2008. According to a report by the International Federation of Robotics (IFR) published in September 2023, the proportion of collaborative robots in the industrial robot market will reach approximately 10% of the total in terms of unit sales by 2022.

Various research companies have released their future forecasts, and in many cases, the market is expected to maintain double-digit growth rates. For example, according to "Robot Future Predictions 2023" published by Nikkei BP in February 2024, the global collaborative robot market is predicted to grow from 126.9 billion yen in 2021 to 2.9727 trillion yen in 2033.

Also worth reading: Case Study: Sankei Industry Co., Ltd.

Introducing collaborative robots to reduce labor on assembly lines

Sankei Kogyo Co., Ltd., a manufacturer of automotive suspension and steering parts in Ritto City, Shiga Prefecture, was looking to improve productivity to strengthen its competitiveness. To address this issue, the company introduced a UR10e to feed parts into assembly machines, and succeeded in stabilizing productivity with repeatable cycle times.

Benefits and challenges of introducing collaborative robots

Benefits of implementation

Space-saving

The biggest advantage of collaborative robots is that they can be installed in a small space. As a result, they can be installed in limited spaces where conventional industrial robots cannot be installed. In addition to being lightweight and compact, collaborative robots can be installed without the need for safety fences, which reduces the amount of equipment required and simplifies the facility configuration. For systems of a certain size, peripheral input/output devices can be connected and controlled directly to the attached robot controller without using a PLC, eliminating the need to downsize or install a control panel.

High flexibility

Collaborative robot systems can be flexibly introduced and adjusted. This feature is made possible by a user interface that is easy to operate even for inexperienced users. In addition, there is a wide range of third-party peripheral devices that can be integrated with robots via plug-ins without the need for design. This means that tasks and operations can be easily modified or changed even after the system is introduced. Furthermore, the robot's small size and light weight make it easy to move the robot's installation location. Conventional industrial robots require long training periods, and the number of people who can operate them is very limited. Furthermore, if adjustments are needed after introduction, support from an engineer is required, making it difficult to make flexible changes. Collaborative robot systems can solve this problem.

Cost-effective

A simpler system configuration reduces the man-hours required for design and construction, shortening the number of days required to set up equipment after purchasing a robot. As a result, the benefits of automation can be realized sooner. Even after installation, the operating rate can be improved by flexibly changing the location and tasks, and the benefits of automation can be enjoyed for a long time, even after the investment is recovered. With conventional industrial robots, it was common to estimate how many years it would take to recover the total investment based on the expected annual revenue of the production line to which they were installed. This made it difficult to make investment decisions for production lines with short product lifespans or where predictions were difficult.

Human Resources Utilization

The process of introducing and operating collaborative robots provides employees with the opportunity to acquire new skills. By using collaborative robots to automate simple, repetitive tasks and physically demanding tasks that traditional industrial robots could not automate, people can be freed up to perform other high-value-added tasks. Furthermore, because even those with no experience can easily learn how to operate collaborative robots, it is possible to develop human resources capable of utilizing robots within the company. Providing opportunities to improve skills also increases employee motivation, making the company a more attractive workplace.

Implementation challenges

Balancing safety and productivity

The challenges faced by collaborative robots compared to industrial robots include their lower payload capacity and slow operating speed. These are issues that cannot be easily resolved because they involve a trade-off with safety. The impact force (momentum F) caused by contact between a human and a robot is calculated by multiplying the mass of the robot (m) including the workpiece by the velocity at the time of collision (v) (F = mv), so simply put, the impact force of a system moving heavy objects at high speeds will be large and unsafe.

To solve this problem, it is possible to choose a robot with a lightweight body, or to use a robot equipped with a safety function such as an area sensor that slows down or pauses the robot when a person approaches.

Read the Collaborative Robot Guidebook

Find out more about how collaborative robots are changing the way we think about automation and the process of adoption.

SME

The concept of facility automation has changed dramatically since the advent of collaborative robots. This guidebook explains the changes in comparison with conventional preconceptions.

Five questions

This guidebook provides easy-to-understand explanations of how collaborative robots can contribute before you consider introducing them.

10 Steps

This is a step-by-step guidebook that explains the points that need to be considered in order to smoothly introduce and utilize collaborative robots.

Collaborative robot adoption cases

Universal Robots are used in over 100,000 production environments every day