Ultima Forma

Concevoir l'avenir de la fabrication aéronautique

In short

JL Corp , a certified Universal Robots integrator based in Lille, Hauts-de-France, has developed an automated water pump wheel balancing solution for KSB , a specialist in valves and pumps. Integrated into its production site in Sequedin, in the Nord department, the cobotic cell is fully secure. Its benefits for the company are numerous, particularly with regard to the quality of finished products, productivity and operator well-being.

JL Corp tackles heavy-euty impeller balancing challenges with cobotic innovation at KSB

The workstation KSB wanted to automate involved balancing water pump impellers, which involves removing material to ensure proper weight distribution across the product. This operation was not only arduous for the operators involved, but also disruptive for the entire production site. On the one hand, it required the lifting of heavy loads, could cause injuries, and was particularly dirty. On the other hand, it generated significant noise pollution, disrupting communication within the teams on site.

In practice, operators had to place the 25 kg wheels on a wheel balancer to determine the amount of material to be removed. They then had to remove them and sand them manually using a grinder—a process that took 30 to 45 minutes. Finally, they placed them back on the wheel balancer to check whether they had removed the correct amount of material.

Performed manually, this operation posed a multitude of problems. Indeed, carrying heavy loads led to musculoskeletal disorders (MSDs), operators could cut themselves while handling the wheels, sanding generated large quantities of dust, and the noise level could exceed 110 dB. As a result, employees dedicated to this position were required to work nights to limit disturbances during the day. In addition, the rendering was often imprecise, requiring the process to be repeated several times before achieving a satisfactory result.

That's why KSB was looking for a solution capable of precisely grinding wheels with reduced noise, while ensuring total operator safety and workplace cleanliness. The company therefore contacted JL Corp, a certified integrator (CSI) of Universal Robots operating in the region.

JL Corp (KSB)

Main value drivers:

Noise reduction Increased security of the post Increased productivity

Tasks solved by collaborative robots:

Balancing water pump wheels

Automation challenges solved:

Reduction of cycle times by 3 Reduction of MSDs among operators Working in hidden time

How they did it

JL Corp delivers rrecision cobotic grinding solution for KSB’s impeller balancing needs

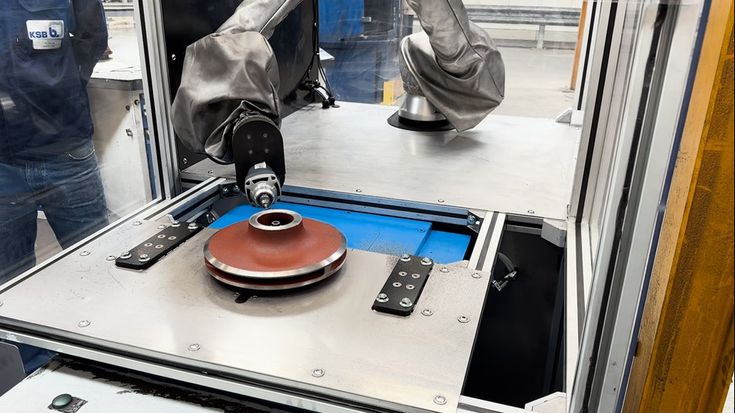

To address the ergonomic, safety, and precision challenges of manual impeller balancing, JL Corp engineered a fully automated cobotic cell centered around a UR10e collaborative robot, equipped with a fire-resistant protective cover and a Bosch Pro grinder with a cutter attachment. A custom-designed human-machine interface (HMI) tailored for KSB enables intuitive operation and easy parameter updates.

Safety was a top priority: JL Corp conducted a risk analysis with Bureau Veritas, leading to CE certification. The system includes a magnetically secured protective casing to ensure operator safety during operation.

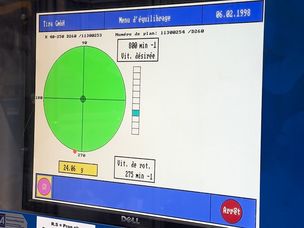

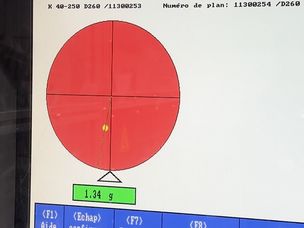

The process now begins with an initial balancing to identify the material to be removed and its location. Operators then use the HMI to input the product reference and removal quantity. Once the cycle starts, the door locks automatically, and the UR10e precisely grinds the impeller based on learned reference points. After grinding, a rebalancing check confirms the accuracy of the operation.

For maintenance, the system includes a dedicated mode that safely repositions the UR10e, allowing quick and secure cutter replacement.

JL Corp’s cobotic cell delivers safer, quieter, and more efficient impeller balancing at KSB

The cobotic solution developed by JL Corp has fully met KSB’s expectations, delivering transformative improvements across safety, productivity, and product quality.

- Operator Safety & Ergonomics:

Manual handling of heavy impellers and exposure to dust have been eliminated. Operators are no longer burdened by repetitive lifting or hazardous grinding tasks, significantly reducing the risk of musculoskeletal disorders and injuries. - Noise Reduction & Workplace Comfort:

The grinding process, once a major source of noise pollution exceeding 110 dB, now operates below 80 dB. This has restored clear communication across the production floor and enabled operators to work comfortably alongside the cobot in masked mode. - Efficiency & Product Quality:

The automated system has tripled the speed of the balancing cycle while delivering unmatched precision. This has led to a noticeable improvement in the quality of finished impellers and reduced the need for rework.

Hugo Marien, Business Manager at JL CorpCe qui m'a le plus frappé avec l'UR10, c'est la facilité d'installation. J'y suis arrivé avec une expérience de codage très basique, et jamais d'expérience en robotique ou en cobots. Mais nous avions le bras déballé, et opérationnel à un niveau de base en quelques heures seulement

Contactez Universal Robots

Des milliers d'entreprises comptent sur les robots collaboratifs pour...

- Augmenter la productivité

- S'adapter à la demande changeante des produits

- Améliorer le bien-être et la fidélisation des employés

- Faire face aux pénuries de main-d'œuvre

- Universal Robots A/S - France

- 13-17 rue Pagès

- 92150 Suresnes