Sensata technologies

Dozens of robots support the production of millions of sensor-rich units

In short

Leading manufacturers of sensor-rich solutions Sensata Technologies moved away from traditional industrial robots for their autoloading processes in favor of the UR3e back in 2020 — paving the way for their Malaysian plant’s transformation through collaborative automation.

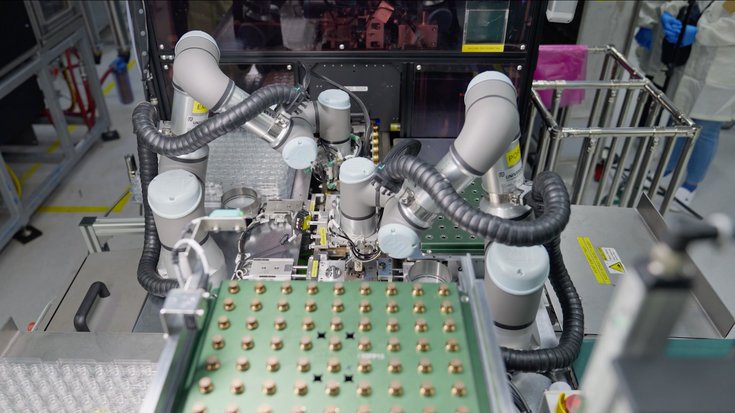

Today, the plant in Selangor leverages dozens of Universal Robots, including UR3e and UR5e, that free up operators, improve safety and increase production output by up to 20%.

The challenge

In the manufacturing of sensor components, many processes remain labor-intensive and require high levels of precision. Manual assembly and handling of components across production lines can introduce variability and inefficiencies, especially in repetitive tasks.

Sensata Technologies

Key value drivers:

Easy to learn programming Robot system deployment can be done in-house without external experts Cobots can be quickly integrated into existing production lines and can be easily scaled up or down depending on production needs. Cobots can be programmed and reconfigured to handle different tasks, making them highly adaptable.

Tasks solved by collaborative robots:

Machine Tending for multiple production cells such as welding, snubbers, cap assembly, and laser coding, among others Pick and Assemble parts into a unit Transfer pallets from machines into welding machines/ovens

Automation challenges solved:

Precision in complex tasks Efficiency in repetitive operations Scalability and quality assurance Enhanced workforce support Improved workplace ergonomics

How they did it

Boosting productivity and safety

The UR cobots have been quickly integrated into existing production lines, assisting with different processes in the plant’s production needs. Their easy-to-use systems granted Sensata instant improvements to production. UR cobots across the plant were programmed and reconfigured to handle different tasks, proving to be highly adaptable to new products or changes in the production process — whether welding, machine tending or palletizing was needed. The cobots’ small footprint also maximizes space within each cell, unlike the previously installed traditional industrial robots which not only took up more space but was a potential safety hazard given its huge stature and close proximity to workers.

Precision automation: raising accuracy and output

Shahrul added: “Cobots can perform tasks with extreme precision, which is especially valuable in sensitive manufacturing processes such as ours in sensor production. They’ve been particularly effective in repetitive operations such as assembly and quality control, where consistency and high accuracy are critical. Automation allows Sensata to maintain high standards of quality and performance while scaling production to meet global demand.”

The deployment of UR cobots has significantly boosted production efficiency by 20% across lines, contributing to a notable increase in daily output.

Integrating systems in-house

Satisfied with the implementation of the UR3e within the production plant, Sensata sent four technical staff over to Universal Robots’ APAC headquarters in Singapore back in 2022 for training. Harnessing training from the cobot manufacturers, the technical staff brought back new knowledge to STM, further enhancing their In-House Automation Team to tackle challenges faced in the plant internally. Divided into mechanical and machining, software and programming, and electrical and technical support, Sensata Malaysia’s In-House Automation Team develops tailored automation solutions to work seamlessly with UR cobots for their needs. Whether there was a need for connectors, grippers, pallet transfers or additions to autoload, the In-House Automation Team engineered solutions that integrate directly with UR cobots across manufacturing cells.

From automation users to in-house innovators

Sensata’s journey with automation is truly remarkable, evolving from simply being users to building a full-fledged in-house automation team capable of deploying, maintaining, and integrating robotics solutions independently. This self-sufficiency is a rare achievement, reflecting the company’s commitment and satisfaction with the performance of UR cobots in their operations. Unlike many companies that may rely on external support for automation, Sensata’s drive to handle every aspect themselves underscores their dedication to operational excellence and innovation, setting a strong example in the industry.

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI