RobotIndus

Robotindus transforms operator workflows with collaborative gluing solution at Steelcase France

In short

Robotindus , the official integrator of Universal Robots, has deployed two UR cobots at the French production site of office furniture manufacturer Steelcase, located in Sarrebourg, Moselle. The objective of this robotic cell: to assist operators in gluing office chair seats. A project that required rethinking the workstation in its entirety.

Enhancing operator safety and efficiency in high-temperature gluing operations

Steelcase , a leading office furniture manufacturer, wanted to improve operator comfort at a seat gluing workstation. The application was integrated by Robotindus at the company's Sarrebourg production site. This site, which has been owned by the American group since 1974, employs between 300 and 350 people and produces more than 600,000 mid- and high-end office chairs per year, some of which are assembled by hand.

The position in question involved considerable strain – including a lot of movement by the operator and going back and forth between work surfaces – and a danger associated with the use of glue heated to over 165 degrees.

Steelcase therefore opted for the cobotics application proposed by Robotindus to improve the ergonomics of the workstation. The solution also had to adapt to the diversity of seat models and improve productivity. The other technical challenge of this application lay in the heat exchange between the pipe containing the 165-degree glue and the robot itself.

Robotindus has been able to leverage its experience in terms of integrating collaborative applications to create an efficient, secure automated system that greatly facilitates the daily lives of operators.

RobotIndus

Main value drivers:

Capacity to develop applications around the cobot Simplicity and intuitiveness of programming Safe operation alongside the operator who keeps control

Tasks solved by collaborative robots:

Gluing the bases Recognition of the product reference All seat references condensed into 2 stations instead of 5. Operators no longer need to move from one station to another.

Automation challenges solved:

Glue diffusion accuracy by the cobot Increasing the cobot's load capacity with a balancer Recognition of references and thickness via a camera and a laser Reduction of MSDs among operators thanks to the height-adjustable workstation Elimination of the risk of burns due to glue Saving on glue usage

How they did it

A cobotic redesign for safer, smarter gluing workstations

The original workstation consisted of 5 separate tables, on which two operators worked, who had to regularly move from one to the other depending on the model of seat to be prepared. They had to superimpose the different layers of the seat base and then glue them, using a glue gun, with their bare hands. The activity was subject to risks of MSDs (tilting of the workstation, repetitive movements, weight of the gun, etc.) and serious work accidents (risk of burns with high-pressure glue, at 165°).

A complete overhaul of the workstation

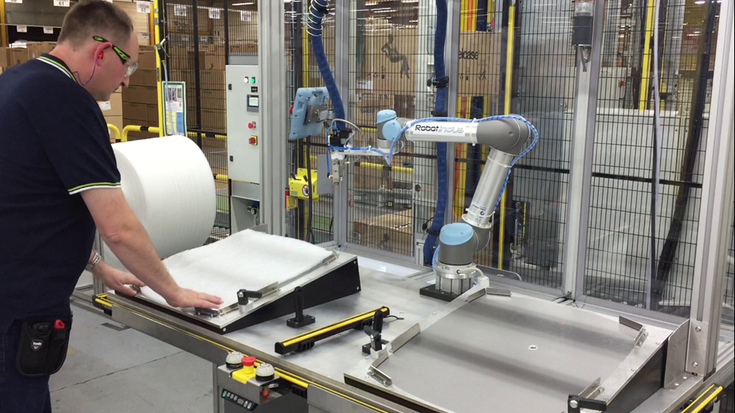

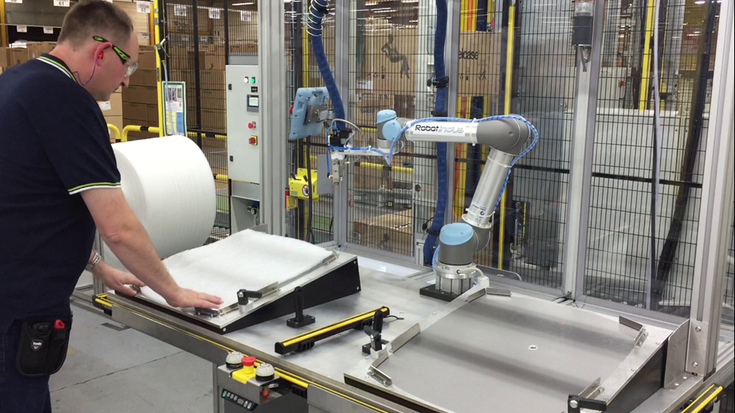

The solution proposed by Robotindus transforms the five existing workstations into two workstations with adjustable table heights - one per operator - which consist of a double secure gluing station. The two gluing stations are equipped with specific fixtures adapted to the different references of parts to be glued, interchangeable very quickly. Each has a UR5 cobot, equipped with a glue gun, a camera and sensors to determine the gluing operation to be carried out. Sensors are used to recognize the reference of the installed tools. Following this phase, the robot will automatically recognize at which gluing stage the seat is located and therefore the quantity of glue to use and the movements to be carried out.

A fully secure solution

The cobot is equipped with sensors to detect the operator's presence. The installation is thus secured by light barriers, between the two stations, in front of the stations and on the sides. If the operator inadvertently enters an area in which the robot operates, the robot immediately closes the glue gun and starts again as soon as the operator moves away. This eliminates any risk of accident. The operator has access to an HMI (human-machine interface) interface to monitor the cobot, ensure the operation is running smoothly and intervene in the event of a problem.

A natural collaboration between man and cobot

The cobot works in parallel with the operator. The latter places the different layers of seat foam on the first station and validates his action. The cobot then glues the latter, while the operator works on the second gluing station. The operator and the cobot thus work together, on different stages of the process, where the operator prepares the layers on which the UR5 works. The robot always waits for the operator to validate the operations before spraying the glue.

A safer, more productive, and ergonomic gluing process

The installation delivered by Robotindus meets all of Steelcase's objectives. Improved ergonomics with two workstations instead of five, reducing the constant movement of operators, who benefit from greater overall working comfort, thanks to height-adjustable workstations.

By assigning the gluing activity to the cobot, the installation drastically improves the working conditions of operators, who no longer have to take on a tedious and high-risk task. They are assigned to higher value-added tasks (supervision, quality control) and which require human labor, in particular the correct superposition of the layers constituting the seat. Today, 250,000 seats are glued per year by the two robots.

On the cobot side, its high precision and excellent repeatability have allowed Steelcase to increase the quantity of chairs produced while improving their quality and finish. The company has also achieved material savings with a 50% reduction in glue used. The position is now simplified and can even be assigned to beginners, offering greater flexibility in assigning tasks to teams.

The installation was delivered in 4 months (from development, assembly, and installation to delivery). The return on investment (ROI) is less than 18 months. The benefits are also and above all measured in terms of ROC (Return on Comfort), with a virtual elimination of accidents in this area.

Raphael Schwartz, Co-manager of RobotIndusOur job as integrators is to create all the peripherals around the robot in order to meet the client's specifications. The particularity was to have a human operator and a cobot handling a risky element cooperate in the same workstation, while maintaining good productivity.

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI