Midgard Inc.

Injection molding ROI in 1,500 hours using collaborative robots

In short

Midgard Inc. has deployed dexterous 6-axis robots from Universal Robots to handle both the tending of injection molding machines and secondary operations in the same cycle, all controlled through UR’s IMMI module that directly interfaces the robot and the injection molding machine. The optimized, automated production process saw a quick return, reduced scrap rate to nearly zero, and improved worker ergonomics.

The automation journey: from 3-axis pickers to dexterous collaborative robots

Initially, Midgard's automation efforts involved more traditional three-axis robots and sprue pickers. However, these early solutions presented limitations. “A lot of our custom components, you can’t handle with a conventional picker,” says Dominic Reina, president of Midgard Inc. "We needed more degrees of freedom to manipulate the part as it releases from the tool.” Another crucial automation challenge was to handle all secondary operations that the molded parts go through such as degating, drilling, deburring, and quality inspection. All tasks performed manually at Midgard. “We discovered UR robots,” says Wes Brown, operations manager at Midgard. “And that’s when things really started to change for us.”

Midgard Inc.

Key value drivers:

Improved competitiveness and efficiency Mitigation of labor restraints Significant cost savings and ROI Increased quality and reduced waste

Tasks solved by collaborative robots:

Picking and placing parts in injection molding machines Degating and deburring Drilling and sonic welding Quality inspection

Automation challenges solved:

Limitations of traditional pickers Programming complexity Real estate constraints Workmen’s compensation risk

How they did it

Secondary processes help deliver ROI in just three months

Midgard has six UR10e cobots (now marketed as UR12e) mounted on top of the presses. The dexterous UR cobots load and unload parts directly into the IMMs (injection molding machines), as they run in automatic mode, while also handling the secondary operations. “We really put the cobots to work, freeing up our employees from having to do these tasks,” describes Reina.

Never having the cobot idle helped deliver an impressive ROI. According to Reina: "By the time we’ve placed that robot on top of our machine, we’re looking at about 1500 running hours for that robot to get a return. Which is about three months of uninterrupted production."

The financial gains have also extended to approximately 30 percent savings on the final piece price for customers. “By automating, we were able to achieve twice the business with less than half the manpower," elaborates Brown.

“Our workmen’s comp insurance absolutely loves us”

When the cobots arrived at Midgard, employees were initially concerned that their jobs may be in jeopardy. Their fears were soon quashed when it became clear that the robots were there to work with them–not replace them. “Before, operators had to constantly cut this, trim that. Now, we have no recurring health issues. All the repetitive motion tasks have been taken over by the cobots now,” says Brown. “Our workmen’s comp insurance absolutely loves us,” adds the Midgard president.

Automation with UR robots has also led to a substantial improvement in product quality. “We’ve seen our scrap rate go from up to ten percent on some days, down to one to two,” reports Brown. “Sometimes it’s not even quantifiable for us in our ERP software. As an injection molder, if you see zero percent scrap on your ERP system, it’s a good day. You’re smiling.”

IMMI module offers easy integration between cobot and IMM

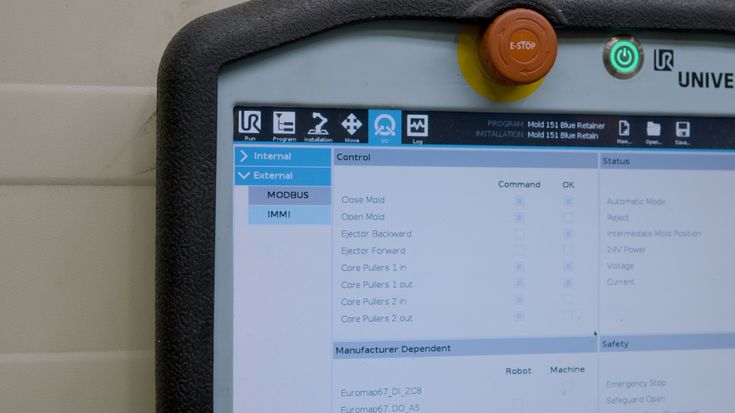

Another delightful discovery was Universal Robots’ IMMI module, a unique software/hardware module that both simplifies interfacing between the robot and injection molding machine itself and provides a programming template. Unlike other robot systems that require extensive coding and complex XYZ plane programming, the IMMI offers a pre-designed program tree. Most of Midgard's machines are Euromap 67 compatible, which aligns perfectly with the IMMI's design.

“It really breaks apart the signals, being able to open and close the press and having part ejection in a certain timeframe, - everything down to core pullers, and air blow, it really does make things easy,” says Midgard’s operation manager. “All you have to do is add the waypoints of where you want the cobot to go.”

Midgard purchased their cobots through UR partner Applied Controls, where account manager Conor Carroll emphasizes how the IMMI sets UR apart. “It’s like starting a race already half-completed, removing all the integration headaches we usually see with robots and IMMs.”

Ease of use made the difference

The IMMI is programmed and controlled directly through the cobot’s 3D graphical teach pendant interface. For Brown, one of the biggest draws to UR’s collaborative robots was their user-friendly programming: “We looked at a plethora of different collaborative robots over the years, and none of them were as easy to program as the UR was. From when we first brought it in the door, to initial setup was just a few hours for us,” says Brown. “It really made a difference on our production team.”

The company has also made extensive use of the UR Academy. “I learned a lot of different nuances on how to properly utilize these robots for all the different things that they can do, such as I/O controls, controlling conveyors, and controlling external forces,” says Brown. “It is a phenomenal platform where you really have complete control over the production process. Product changeovers usually take anywhere from a few minutes to no more than an hour.”

In the future: No IMM purchases without a UR cobot

At Midgard, there's a growing commitment to integrating UR robots into their manufacturing processes. Previously, Brown explains, a UR robot was mounted on a mobile cart in the assembly department, where it significantly improved secondary post-molding operations like ultrasonic welding and pad printing. Although the robot was temporarily relocated due to production needs, the company plans to reintroduce this approach in the future. “After the first time a customer implements a robot, typically they start buying more because ultimately, that speaks to the success of the installation,” says Carroll. A scenario echoed by Midgard’s president: “Right now, I think we have to retrofit about ten more machines to have robots on them,” says Reina. “We will never purchase another machine without having a UR on that machine.”

UR+ products used:

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI