Mercedes-Benz

Improving glue application processes with collaborative robots

In short

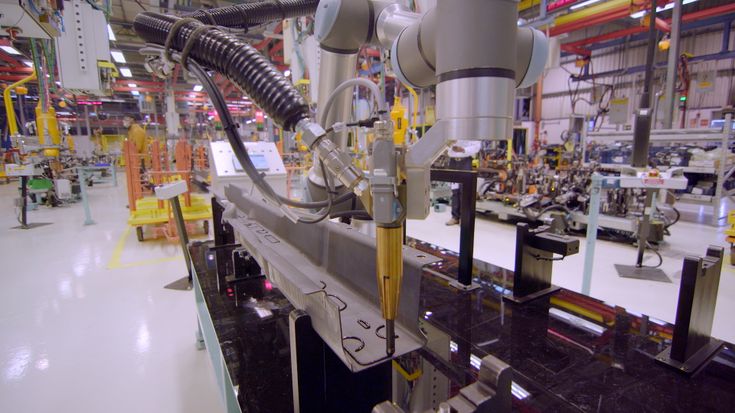

Mercedes Benz factory in Juiz de Fora (Minas Gerais, Brazil) had started implementing Industry 4.0 strategies in 2012, but in recent years saw the need to go a step further and apply collaborative robotics to its production line. With a UR10e (now marketed UR12e), the factory automated the application of glue to stringers to reduce rework and ensure truly efficient prevention of parts’ oxidation.

The challenge

Looking to cut down on rework during the glue application to automotive side members, Mercedes-Benz set out to make the process more precise through targeted production changes. They needed a solution that could deliver consistent, predictable dosing while also improving workplace ergonomics.

The challenge was to automate the glue application process quickly, within a fixed budget, and without overhauling the entire factory floor. At the same time, the new system had to work safely alongside human operators, ensuring there were no risks to health or safety on the production line.

Mercedes-Benz

Automation challenges solved:

Reduction in rework Increased productivity Improved ergonomics

Key value drivers:

Easy installation and programming Reliability Safety

Tasks solved by collaborative robots:

Applying glue to stringers

Increasing precision and reducing rework

Mercedes-Benz implemented a UR10e (now marketed as UR12e) collaborative robot on its production line to apply glue to automotive parts. This task had traditionally been physically demanding and highly repetitive. The glue tool was heavy, and the process, though essential for ensuring the final product’s quality by preventing part oxidation, offered little ergonomic comfort to workers.

With the UR10e, Mercedes-Benz was able to relieve employees from this strenuous task and reassign them to more valuable roles on the production line. The result was a reduction in rework and production delays caused by human error. “The robot now delivers the perfect quality demanded by Mercedes-Benz,” said Rogério Dutra, Production Supervisor at the factory. “And we can also take advantage of the workforce to further enhance the product.”

A safer and more productive workplace

The implementation was quick, smooth, and highly productive, improving both workplace safety and quality of life for the team. “Having a collaborative robot working right beside you, and knowing it ensures your safety, is paramount,” said welder Robinson Pires. The UR10e operates safely without a protective cell and automatically stops if it comes into contact with a person.

Through automation, Mercedes-Benz not only improved its assembly line processes but also created opportunities for employee growth and professional development, resulting in positive outcomes across multiple areas.

José Almeida, Maintenance Planner at Mercedes-BenzIt's a very simple robot, a very user-friendly interface. We are learning a lot every day and we hope that in the future we will have other components, other robots similar to the one we have now.

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI