Mandom Co., Ltd.

Building an Unmanned Line Using UR Robots

In short

Mandom Co., Ltd., a manufacturer and seller of cosmetics, fragrances, and quasi-drug products, introduced robots in order to acquire the technical capability to automate processes in-house. The company adopted UR robots, which are easy to program and intuitive to use. By successfully building the line internally, Mandom reduced costs previously spent on outsourcing and, at the same time, gained the technical capability to design and build production lines on its own.

Challenges

In response to labor shortages, Mandom considered building an unmanned production line.

“Until now, we had introduced dedicated labor-saving equipment, but it lacked versatility and involved high costs. We believed that by using robots, we could eliminate dedicated parts and make changeovers easier, which is why we decided to move forward with automation,” says Naoki Sasagawa, General Manager, Production Engineering Division, Mandom Co., Ltd.

The company also considered conventional industrial robots, but programming would have required outsourcing, and they were not suitable for Mandom’s high-mix, low-volume production.

Mandom

Solution - UR Cobots

Building an unmanned line in-house using UR collaborative robots

Mandom decided to build an unmanned line centered on collaborative robots.

“Among the robots from several manufacturers, UR robots were the easiest to use and the most intuitive to operate. Also, as a global company, we felt it would be easy to deploy them at overseas factories,” says Masaru Ono, Section Manager, Production Engineering Section, Production Engineering Division, Mandom Co., Ltd.

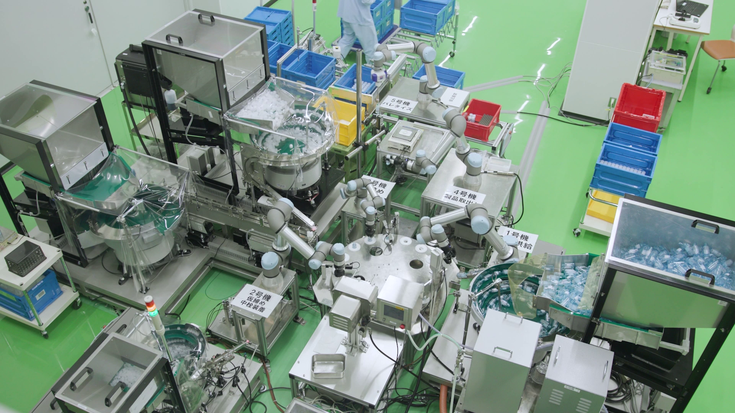

After verifying what robots could handle during the process design phase, Mandom introduced a UR5e for the cap-tightening process in October 2020. Over the following year, six additional robots were added.

As a result, the entire series of processes—from inserting liners into bottles and tightening caps, to transfer, printing, inspection, and palletizing—was automated using robots.

How they did it

First, a UR5e picks up bottles supplied from a feeder and places them on a turntable. After the bottles are filled with liquid, the UR5e inserts liners into the bottles. At this stage, the robot’s built-in force sensor is used to insert the liner straight and confirm that it is properly seated.

For products without liners, such as pump bottles, this process performs provisional tightening.

Next, a UR3e supplies and tightens the caps. The UR3e’s infinite rotation wrist is effectively utilized for the cap-tightening operation.

“If the cap is tightened too much, it becomes difficult to open. If it is too loose, liquid leakage can occur. To prevent this, we control the tightening torque using the UR3e’s built-in force/torque sensor to achieve the optimal condition,” says Junki Ueda, Group Leader, Production Engineering Section, Production Engineering Division, Mandom Co., Ltd.

Sensors attached to the turntable detect whether the cap is properly installed, and the UR5e transfers acceptable bottles to the next process. After weight measurement, the UR5e performs inkjet printing and then places the inspected products into containers.

Peripheral devices such as feeders and turntables are connected to the robots via PLC I/O.

“We used the palletizing templates built into the UR robots to arrange products in the containers. You simply follow the instructions and input the stacking pattern, so programming was easy,” they explain.

The biggest challenge was reducing cycle time.

“To shorten takt time, we focused on simplifying robot motions and optimizing the layout while coordinating with peripheral equipment. As a result, we were able to achieve our target,” they say.

In this project, Robotiq electric grippers and Schmalz vacuum grippers were also used.

“Because these grippers can be operated directly from PolyScope, there was no need to design special gripper control, which was very convenient and helpful,” says Junki Ueda, Group Leader, Production Engineering Section, Production Engineering Division, Mandom Co., Ltd.

By designing, commissioning, and operating the line entirely in-house, the team deepened its understanding of robot characteristics and improved its utilization skills. This experience also enhanced their internal technical capabilities.

Masaru Ono, Section Manager, Production Engineering Section, Production Engineering DivisionBy designing and commissioning the line ourselves and actually operating the robots, we improved our knowledge and utilization skills. We feel that we can further expand the scope of robot usage.

This overall increase in our internal technical capability has been a major benefit.

Benefit

Previously, Mandom outsourced the production of approximately 40,000 to 50,000 trial product bottles per month. By building an unmanned line in-house, the company is now able to handle all of this internally, achieving cost reductions.

Going forward, Mandom is considering expanding the application of the line to a wider variety of products and deploying the same equipment at overseas factories.

About Mandom

Founded in December 1927, Mandom Co., Ltd. is a manufacturer and seller of cosmetics, fragrances, and quasi-drug products. In addition to Japan, the company has manufacturing and sales bases in Southeast Asian countries such as Indonesia, where it develops business that meets local consumer needs.

Key value drivers:

Easy programming enabled in-house robot system development Proven global deployment and support track record

Tasks solved by collaborative robots:

Bottle liner insertion Cap tightening Transfer to printing and inspection Palletizing

Automation challenges solved:

Successfully internalized a production line previously outsourced Improved internal technical capabilities

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI