GAPE

GAPE drives welding innovation at Tramétal with cost-effective cobotic integration

In short

GAPE , integrator of Universal Robots in the Nouvelle-Aquitaine region, has developed an automated welding solution on behalf of Tramétal , a company specializing in subcontracting in precision thin sheet metal.

The welding cobot, installed at the Isle-Jourdain site, serves a dual purpose: simplifying programming and saving time for small and medium-sized production runs. Developed specifically for this purpose, this project has helped optimize production, improve working conditions for welders, and contribute to the attractiveness of Tramétal.

GAPE tackles workforce and efficiency challenges at Tramétal

To meet Tramétal’s need for a more agile welding solution, GAPE leveraged its deep understanding of welding processes to develop a cobotized system tailored for small and medium production runs. While Tramétal already operated five traditional welding robots, the company sought a more flexible and user-friendly alternative to ease the workload on welders and improve accessibility.

The key challenge was to simplify programming—Universal Robots’ cobots offered a faster, more intuitive setup compared to conventional robots. To further enhance usability, GAPE eliminated the need for the standard teach pendant, replacing it with a single-button waypoint recording system. This innovation made the solution accessible to operators without welding expertise or industrial backgrounds, directly addressing the shortage of qualified welders in the job market.

By focusing on ease of use, adaptability, and workforce inclusivity, GAPE delivered a solution that not only met Tramétal’s technical requirements but also supported its long-term talent strategy.

GAPE

Main value drivers:

Simplicity and intuitiveness of programming Safe operation thanks to casings Increase in production rate Fast ROI

Tasks solved by collaborative robots:

Welding point identification and simulation Welding activation using a button Preparing a new cycle on a second table

Automation challenges solved:

Ease of use Reassignment of the welder to higher value-added tasks Improved security

How they did it

Precision welding reimagined: GAPE deploys advanced cobotic MIG welding cell for safer, smarter operations

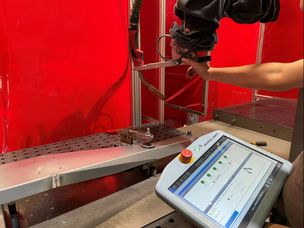

The MIG arc welding application developed by GAPE consists of a UR10e cobot on which a Fronius torch and a button specifically developed for manual validation of weld points are positioned. The cobot - mounted upside down on a jib crane - works simultaneously on two metal tables for increased workstation efficiency. The cell is enclosed to protect operators from arc flashes or other incandescent particle projections and eliminate the need for them to systematically wear a helmet.

A preparatory mode with simulation

To perform the desired welds, the operator must first manually record a first waypoint and then all the intermediate points (if any) up to the end point of the trajectory. To do this, the user directly takes the cobot - free of any movement - in hand to teach it all the positions using the validation button.

The cobot has a range of movements - previously recorded by the Tramétal reference welder - on 6 axes (linear, circular or arc) that it can chain together to create complex movements and perform the appropriate welding for various types of parts.

The user can also adjust the speed and choose the welding mode suitable for different types of material. These operations are carried out very intuitively via a system of pop-ups integrated into the teach pendant.

The recorded movements are then carried out by the cobot without activating the weld for verification. If necessary, the operator can then insert new points or modify the speed.

Precise and repeatable work, accessible to all

Once the checks are complete, the operator can start the welding cycle by pressing a start button on the station. The cobot then performs welds with precision equal to or greater than that of welders, maintaining a consistent rate. This results in quality finished products and reduced downtime due to the reduction in rework required.

The cobot can repeat the exact same weld as many times as needed, ensuring consistent and reliable production. This is particularly suitable for small and medium-sized production runs.

At Tramétal, the choice was made not to assign their qualified welders to this position, but rather to employ people with little or no welding skills. This choice was made possible by the extreme simplicity of programming the solution developed by GAPE.

A secure position on two separate tables

The entire welding station consists of two tables, each enclosed, and a cobot positioned between the tables. To ensure operator safety, sensors ensure that welding only begins when the cover is closed. If the cover is opened during welding, the robot and the process stop immediately. This protects against UV rays emitted by the torch, as well as spatter and smoke, eliminating the need for a safety helmet.

The operator can work simultaneously and safely on the second table, remove the welded part and install a new one while the cobot works on the first table. GAPE's solution thus meets Tramétal's requirements and working habits by combining the cobot's autonomy with safety measures for productivity gains thanks to working in masked time.

Elevating industrial welding: GAPE’s cobotic MIG cell combines safety, precision, and efficiency

The custom cobotic welding solution developed by GAPE has delivered strong operational and human-centered outcomes for Tramétal:

- Simplified Programming: A custom button system allows easy waypoint validation, enabling non-specialist personnel to operate the station—streamlining recruitment and training.

- Productivity Gains: The cobot matches the output of Tramétal’s top welder, reaching 220 parts/day, with a minimum 10% increase in productivity.

- Workforce Optimization: Skilled welders are now freed up for higher value-added tasks, improving overall resource allocation.

- Rapid ROI: The investment paid off within just a few months, proving the solution’s economic viability.

- Improved Safety & Ergonomics: Enclosed cells and reduced physical strain have led to better working conditions and lower MSD risks.

- Future Scalability: Tramétal plans to expand cobotic applications to machine loading/unloading, reinforcing cobotics as a strategic asset—especially attractive to younger talent.

Didier Crenn, GAPE DirectorWe wanted to offer the easiest solution for welders to use. We brought our automation expertise to bear with a system for recording waypoints using a single button. This means that even a non-specialist operator will have no trouble getting to grips with the application.

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI