Firac

FiRAC simulates real-life automotive assembly line conditions to advance screwdriving applications

In short

FiRAC , a SNEF Group company, helps businesses integrate more lean, flexible, scalable, and intelligent industrial processes. Specializing in the design and deployment of robotic solutions, the group has been operating in the automotive and aeronautics sectors for over 40 years.

An integration partner of Universal Robots since 2015, FiRAC recently successfully integrated two cobots onto an assembly line at a Stellantis (PSA and FCA group) plant in Sochaux. The integration was completed in record time and the benefits are already being felt by the customer.

Enhancing ergonomics and quality in wheel component assembly

As part of its Factory of the Future project, the PSA group has automated part of its wheel component assembly line.

Alongside the constantly moving main assembly line is the secondary flow. This section is where parts are prepared and activities such as screwing and quality control are carried out on the product being manufactured. Here, handling is carried out by 13 AGVs. They follow a predefined circuit and load equipment and tools. They stop while operators perform the screwing operations, which are precise, repetitive, and tiring.

The objective of the application was to improve the ergonomics of workstations as well as the quality of operations.

Firac

Main value drivers:

Operating safely alongside operators Fast ROI, minimal maintenance Productivity gain Quality improvement

Tasks solved by collaborative robots:

Screwing into hard-to-reach corners Repetition and precision of the gesture Carrying very heavy screwing tools

Automation challenges solved:

Reduction of MSDs of operators by performing a physically demanding task Evolution of operators on tasks with higher added value Easy integration into the existing production line

How they did it

Automating repetitive screwdriving tasks with collaborative robotics

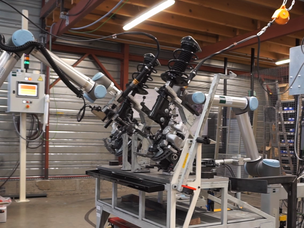

The choice fell on two UR10 robots from Universal Robots capable of carrying out a wide range of operations thanks to their long range and an on-board payload of 10Kg.

In this case, the operator was screwing brake disc protectors onto half-axles of a vehicle.

This is a position with no added value, where the operator holds heavy tools all day long to repeatedly screw parts into sometimes difficult-to-access corners. This arduous task requires a rotation of operators. In addition, the difficulty of the task meant that errors were inevitable and rework was frequent.

An application requiring ingenuity

The project presented several challenges. First, the architecture of the line, as the supply flow is managed by a fleet of AGVs. This implies significant variability in the stopping position of the parts at the robot station. The system therefore had to be able to locate itself in space and measure the position of the product to be worked on. To do this, FiRAC opted for a two-step recalibration: First, a telemeter system measures the stopping position of the AGV. Then, one of the two robots in the system takes an image of each product using an onboard camera, thus freezing the final position of the products in space. The position data is then sent to the second robot, and operations can begin. Once the work reference (i.e., the cobots' ability to dynamically adapt to their environment) was set, the FiRAC team was able to focus on the task itself: screwdriving.

FiRAC was able to manage the difficulty of the AGV supply flow: a UR10 with an on-board camera freezes the final position of the products in space before launching the screwing cycle carried out by the second UR10.

A new challenge arose: the impact of the interaction between robots, parts to be screwed, trolleys, and AGVs. To address this, the integrator replicated real-life conditions in its lab. " The best way to ensure efficiency is to avoid spending too much time on theory ," says Stéphane Marnat, Agency Director. FiRAC therefore carried out a dry run, in addition to virtual simulations, to test and adjust the equipment in real-life conditions. All that remained was to set the cycle time. On this project, it was relatively short, and it took some clever thinking to screw the 10 components repeatably and at the required speed.

A cobot supervised by humans

For this application, the entire PSA team - line driver, production manager, maintenance personnel and all those working near the cobot - received training at different levels to be able to intervene on the cobot in the event of a problem.

It's the local operators in particular who have seen their roles evolve. They are now responsible for supervising the cobot's work and intervening in the event of a breakdown. They then check to see if they can restart the robot themselves. If they can't, they call the line manager and, as a last resort, the maintenance department.

All were trained to ensure the maintenance of the installation in record time. To do this, FiRAC offered several modules based on UR Academy 's online training .

Faster integration, safer workstations, and higher productivity

The application developed by FiRAC with the integration of UR cobots limits repetitive movements imposed on operators and reduces the risk of MSDs . It increases productivity and production quality.

The factory operated 3 shifts during the week and 12 hours on Saturdays and Sundays. The cobot was installed at the end of October 2019; the first training sessions took place at the end of November 2019, and everything was completed by December/January. The schedule was met thanks to the strong commitment of production and maintenance staff.

In total, the project took between 2 and 3 months, taking into account the various constraints of the client's schedule. This was a quick turnaround time, as this was not the first time the PSA Group had integrated robotics. The other reason was that Universal Robots cobots are specifically designed to be easy to integrate into an existing production line. All of this, combined with FiRAC's experience, made it possible to integrate the cobots much more quickly than with traditional industrial robots.

Stéphane Marnat, Automation, robotics and cobotics manager FiRAC, SNEF groupIt was an extremely rapid deployment that took us between 2 and 3 months. The schedule was met thanks to the strong commitment of production and maintenance staff.

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI