Centerline Brackets

A million welds and zero downtime

In short

The robust performance of the cobot welder at Centerline Brackets led the Florida-based manufacturer to an exceptionally rapid return on investment, achieved in less than three months. The cobot dramatically cut production time and addressed labor shortages while ensuring consistent weld quality for heavy-duty brackets, solidifying the company's commitment to guaranteed same-day shipping and ‘Made in America’ manufacturing.

A surprising discovery

“In an environment like ours, a piece of equipment doesn't usually last that long,” says Chris Smith, managing partner in Centerline Brackets. “Anytime you have actuating joints combined with repetitive motion, something is going to break sooner or later,” he states, pointing at ‘Teddy’ as the Vectis Cobot Welding Tool powered by a Universal Robot arm is affectionately called. But after two years and seven months of production, Teddy is still welding brackets non-stop with no failures or downtime. “We were surprised. It’s never failed or been on break for 45 minutes,” recalls Smith. “The thing just runs great, - it has done over one million welds now,” he concludes, adding that the company has become so reliant on the cobot welder that they even bought a second system from Vectis as a backup. That cobot has not been in use yet.

Centerline Brackets

Key value drivers:

Delivered ROI in less than 3 months Reduced weld time per bracket from 7-8 minutes to 1 minute or less Produced over 1 million welds in less than 3 years without failure Increased capacity, allowing 2 welders and 1 cobot to achieve the same output as 8 welders previously Enabled ‘same day shipping’ & ‘Made in America” pledges Fast setup and easy programming

Tasks solved by collaborative robots:

MIG welding of 2-inch flat bar steel brackets to produce heavy-duty supports for countertops, shelves and shower benches. Future tasks will involve welding of aluminum products

Automation challenges solved:

Solved labor shortages as employee turnover occurred and positions were hard to fill Addressed manual variability in consistency of welds Boosted morale by eliminating excessive overtime and repetitive welds, allowing staff to focus on higher value-add tasks while leaving at a decent time. Streamlined production, enabling competition with overseas companies

From 8 to 1 minute per weld

Centerline Brackets has built a reputation on crafting heavy-duty American-made steel supports. This commitment to quality is crucial, as their products must consistently support hundreds of pounds. Prior to adopting collaborative robots, Centerline Brackets relied on manual welding, a process that consumed about seven minutes to eight minutes per bracket. “And you could tell who had built it based on the quality of the weld,” says CEO of Centerline Brackets, Tracy Smith. “We needed consistency.”

With the cobot welder, each bracket now takes a minute or less. “It’s a huge time saver,” says Chris Smith. “We’re now doing the same amount of production with two welders and a cobot as we were doing with eight welders before.” The arrival of the cobot, however, did not cause layoffs. “During COVID we struggled with high turnover, the cobot just gradually took over those positions,” says Tracy Smith.

“Easiest money I’ve ever made”

Initially, the Smiths had anticipated an ROI on the cobot within a year. “It paid itself back within less than three months – it’s the easiest money I've ever made,” says Chris Smith, who is quick to point out that the cost savings were not the primary driver. “Our intent was to make the process smoother and not be at the mercy of the employment pool available around here,” he explains, adding that the financial results delivered by the cobot also gave Centerline the ability to pay employees “a good chunk more than they were making before.”

A transformative discovery at FABTECH

For years, Centerline Brackets had explored robotic automation but had yet to find a product that could be safely integrated into their environment. That changed when Chris Smith, having already researched Universal Robots and Vectis software, attended the FABTECH show in Chicago. “We went to Vectis’ booth, and I was just amazed by what I saw,” he says. “I was particularly impressed by the cobot's very accurate and super safe design, and the ease of setup.” The Centerline team made an immediate decision, purchasing a show model directly off the FABTECH show floor.

Setup in half a day with no robotics experience

The implementation was swift. “From the time that we got the cobot in the door, assembled, and programmed running our parts, was about a half a day,” recounts Chris Smith, who tasked his assistant shop manager Cody Cox with programming and being in charge of the cobot. Cox was uneasy at first: “I weld by hand. I’ve never seen a robot, I’ve never used a robot. And I’m not great with computers,” he says.

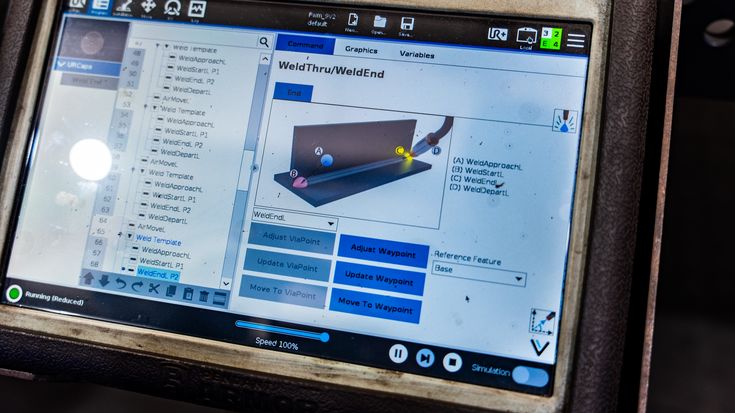

But the shop manager had the cobots welding parts in less than two hours. “You have your fixtures on the table, start your program, set your waypoint, start your ends, your air moves, run your simulation, and that's pretty much it,” he summarizes, adding that product changeovers happen in less than a second. “The four products we weld are all pre-saved on the cobot’s teach pendant, you simply just start that program,” Cox explains.

Boosting employee well-being and morale

Due to its location in St. Augustine, Florida, the weld shop at Centerline Brackets quickly gets hot and humid. “When the cobot arrived, we eliminated overtime right away,” says Tracy Smith. “In the summer, our staff gets overworked and slows down. The cobot doesn’t do that.” Chris Smith recalls how his team used to be at the shop every night of the week until 7 or 8pm. “Now we’re out of the shop by 3 or 4pm, it makes it a lot more livable instead of having your head down in a welding mask for 12 hours a day,” he says. “It’s super important to have a good culture inside of your business and also being a place where people feel comfortable and they want to work. The cobot helped us accomplish that.”

Enabling same-day shipping and “Made in America” commitments

Centerline Brackets prides itself on guaranteed shipping if an order is placed by noon, adopting a ‘just-in-time manufacturing’ model. “That’s what we’ve built our reputation on,” says Tracy Smith. “Now we don’t worry about being able to fulfill orders or meet our obligations, because the cobot actually keeps us running ahead of the game most of the time.”

The cobot has also been crucial in upholding Centerline's commitment to ‘100% American-made in-house’ products. Chris Smith explains that the speed of the cobot and the fact that it takes labor cost disparities out of the equation, enables Centerline to compete with overseas manufacturers. “It makes it easy to make things in America," he states.

Next up: Aluminum welding

Centerline Brackets is now exploring deploying their second cobot for a different product line involving heavy-duty aluminum products. “It makes no sense to have a human standing there doing a zillion small welds, it’s a great job for the cobot,” says Chris Smith, who doesn’t hesitate in recommending any weld shop owners to go into cobot welding: “If you’re still wondering whether it’s a good idea, just go do it. Or come down to my shop and watch it in action. And you’ll be a believer that fast.”

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI