How flexible automation is redefining electronics

Discover how flexible automation, from collaborative robots to AMRs, are helping electronics manufacturers overcome precision, high-mix, low-volume and fragile component challenges while boosting productivity.

The electronics industry is dyamic and demanding. For decades, manufacturers have pushed boundaries to meet global demand. They’ve adopted automation, optimized processes and scaled operations, tackling pressures like labor shortages, cost volatility, and requirements for high-mix production along the way.

Why it matters: These challenges, combined with outdated views of automation as “only for high-volume tasks,” keep many manufacturers from realizing the technology’s full potential – and electronics is no exception.

Enter UR and MiR for greater flexibility in electronics

Modern automation is rewriting the rules. Advances in collaborative robotics and autonomous mobile robots (AMRs) allow manufacturers to automate delicate, variable tasks once thought impossible.

Cobots in electronics manufacturing

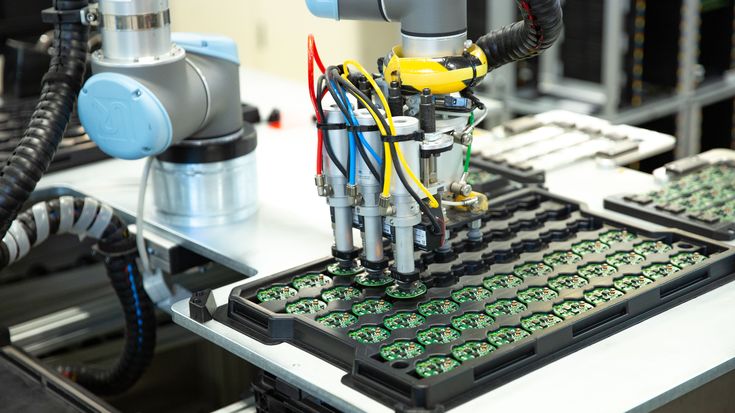

Cobots assist workers with assembly tasks such as screw driving, gluing, soldering, assembling, lift assist, and bin picking. Any situation involving repetitive or unergonomic tasks is worth investing in a cobot application. In offsite fabrication or pre-fab shops, cobots can orient parts for final screw torquing or bring wires together for human crimping. With vision systems and specialized tools, cobots can even handle delicate tasks like automated crimping and quality inspections.

The value of AMRs and mobile manipulators

AMRs safely resupply employees with pallets of raw materials or transport goods between areas of the floor or dock. Combining cobots with AMRs creates mobile manipulators capable of picking and delivering materials between workstations, ideal for flexible production environments.

Proven performance at a glance

25% productivity boost at Melecs

Melecs, a leading electronics contract manufacturer, faced the challenge of packaging two million automotive PCBs annually. By deploying cobots for tray loading, boxing, and lid closing, Melecs achieved:

- 25% productivity increase

- ROI in under 18 months

- Operators freed from repetitive tasks

Optimizing multi-floor logistics at Flexcon

By automating complex logistics, Flexcon has optimized its internal, multi-floor material flow while significantly reducing the physical burden on its workforce. Flexcon achieved:

- ~1,000 items processed per shift

- Elimination of manual walk time and touches

- Reduced physical strain and manual data entry

Keep exploring electronics automation

Ready to see how UR and MiR can transform your electronics operations? Book a demo today.

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI