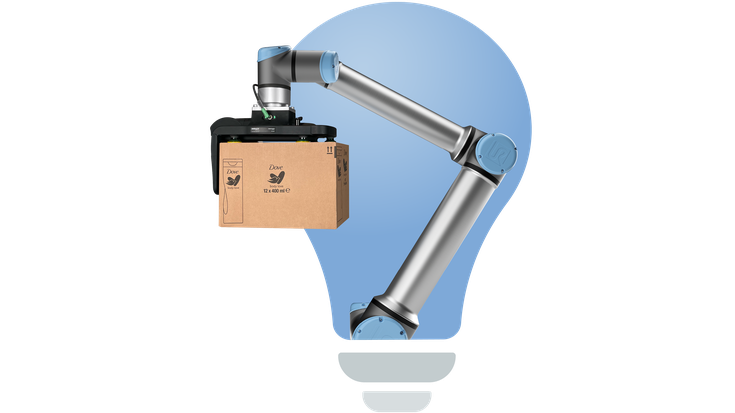

Automate packaging. At the speed of your business

Short on skilled labor? Under pressure to boost throughput and cut costs fast? You are not alone. Many manufacturers in Food & Beverage and FMCG are automating end-of-line tasks to stay competitive. The difference: with Universal Robots, deployment takes days, not months. And the ROI follows in as little as 12 months.

Read the free eBook to see where automation could save you the most end of your line!

End-of-Line anything. Optimize everything

Whether it’s palletizing, case packing, or labeling: Imagine automating your end-of-line processes in just a few days – without disrupting your operations – and delivering immediate efficiency gains.

With our flexible collaborative robots (cobots) this becomes reality. They handle even the most demanding tasks reliably. That means you can free up your team for higher-value tasks and keep your line running 24/7 – all within a remarkably small footprint.

Why to choose Universal Robots?

- Boosts productivity by up to 40%

- Trusted by 100,000+ deployments worldwide

- Integrated into your existing line with minimal disruption

- Backed by the world’s largest partner ecosystem and global support

Learn more about our solutions that not only solve your current challenges but also grow with your business – fast, flexible, and reliable.

Your smarter packaging starts here

From palletizing to case erecting, automate your packaging processes. Our flexible cobot solutions fit right into your existing production lines. They will help you eliminate bottlenecks and accelerate your shipping – so you can meet customer demands faster and more efficiently.

Fast-track deployment. Supercharge ROI

Time is money. That’s why our cobots pay off within 12-18 months and integrate smoothly – without interrupting your operations. With built-in compatibility for your existing ERP, MES or WHM systems and 500+ plug-and-play options, setup is fast, and scaling is straightforward.

Always-on efficiency. Built to accelerate success

By automating routine tasks with cobots, you will see a 20% boost in productivity and a 40% increase in your overall equipment efficiency (OEE). Cobots can run 85,000+ hours without failure. That’s how you can minimize downtime and achieve more with your current resources.

Intelligent automation. Future-ready innovation

Achieve up to 24% faster cycles with our advanced automation. Thanks to our software PolyScope X, you can easily adjust the solution, when your production changes and SKU swaps. Flexible layout options allow you to quickly adapt to new setups, keeping your operations agile.

Deploy now, recover your investment in 12 months!

Nick Chow, Engineering and Fabrication manager at Bob’s Red MillI was surprised! It's a hefty cobot that gave us confidence it would be robust enough to keep up. We appreciate the simplicity, the track record and the out-of-the-box features.

Optimize End-of-Line. Get your free eBook today

Discover how cobots can boost throughput and cut costs end-of-line. This eBook covers everything you need to know about implementing our solution.

Featuring examples from companies facing challenges like yours.