Ultima Forma

Kształtowanie przyszłości produkcji lotniczej

In short

Emanor , an integrator positioned on the industrial process automation market since 2019, has carried out the integration of the cobotic gluing project within the company SIMP Production. The machine has been installed since January 2022 and meets a dual objective: to enable a robot to collaborate safely with employees and to achieve considerable time savings, particularly for the cleaning phase. Developed to measure, this project has made it possible to optimize production and reduce material losses, while replacing the fitter in a position with higher added value.

Improving ergonomics and precision in aluminum joinery assembly

The project was initiated by SIMP Production with the goal of enhancing the ergonomics and efficiency of its gluing and assembly station for aluminum joinery profiles. At the time, fitters were required to perform repetitive, physically demanding, and messy tasks that demanded a high level of precision.

These manual operations not only posed ergonomic risks but also impacted productivity and consistency. The challenge was to develop a solution that would relieve workers from strenuous tasks, maintain high assembly accuracy, and streamline the overall process without compromising safety or quality.

EMANOR

Main value drivers:

Capacity to develop applications around the cobot Simplicity and intuitiveness of programming Safe operation alongside the operator who keeps control

Tasks solved by collaborative robots:

Quality inspection Depalletization Assemblage

Automation challenges solved:

Increasing the cobot's load capacity with a balancer Management of acceleration and deceleration of balancer movements Shape recognition via sensor Reduction of MSDs among operators Traceability of each part by scanning a QR code

How they did it

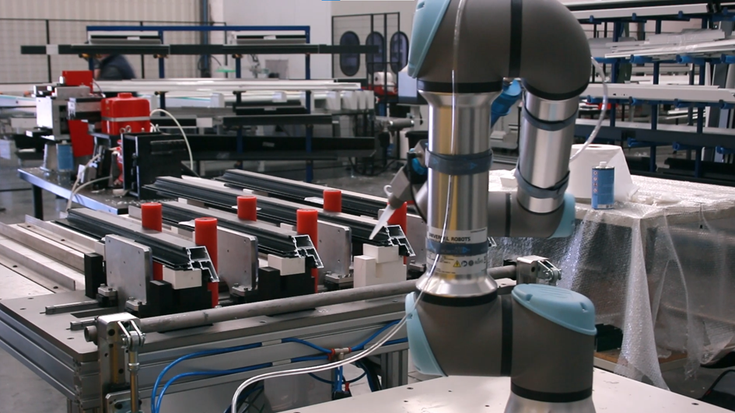

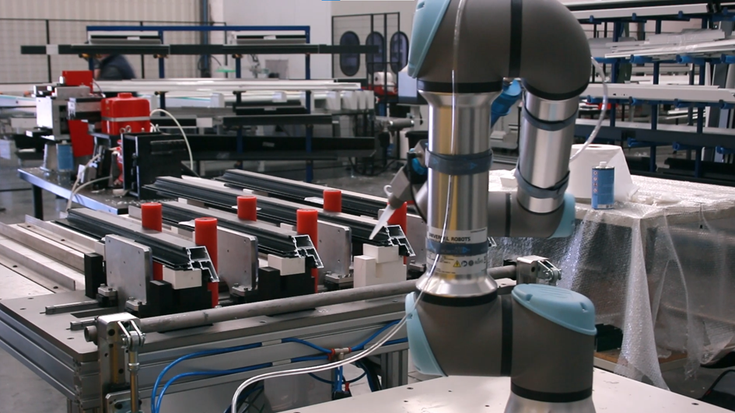

Compact and collaborative gluing automation with UR5e

To meet the growing production demands at SIMP Production, Emanor engineered a compact, secure, and high-performance cobotic gluing solution powered by the Universal Robots UR5e. The system was designed to seamlessly integrate into the existing workflow while enhancing both productivity and safety.

Emanor provided end-to-end support throughout the project lifecycle—from design and customization to installation and operator training. Prior to automation, the gluing process was entirely manual: installers held an aluminum profile in one hand and a glue gun in the other, carefully applying adhesive in precise patterns and quantities. This repetitive task required high concentration and physical effort, often leading to fatigue and inconsistencies.

The UR5e cobot now automates this delicate operation with consistent accuracy, ensuring optimal glue placement while freeing operators from strenuous manual labor. The result is a streamlined, ergonomic, and efficient gluing process that supports higher output without compromising quality.

An automated and optimized workstation

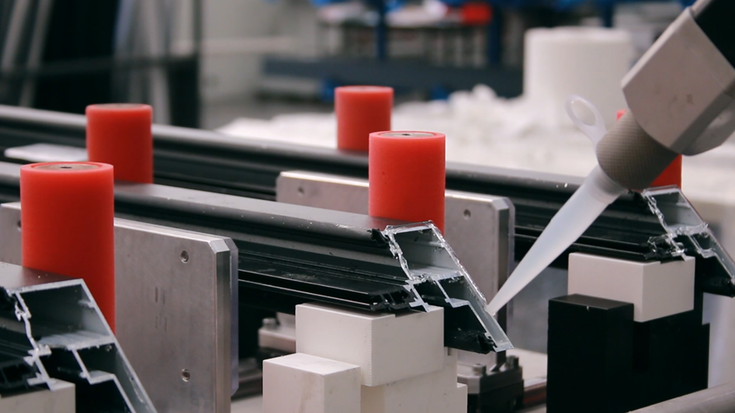

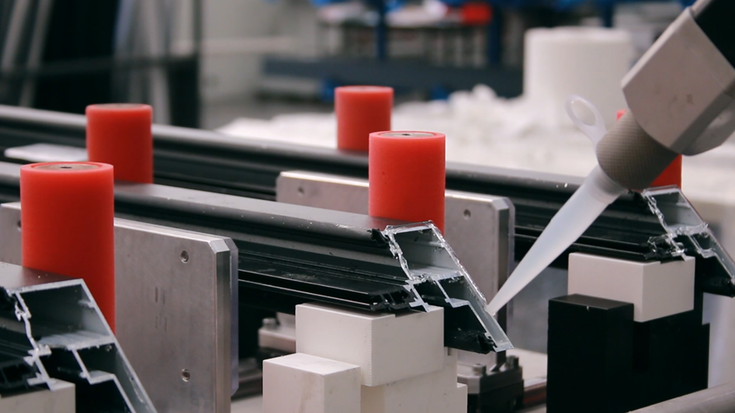

The automated workstation consists of a wedge, at the end of which a UR5e is installed on a table. The collaborative robot integrates easily into its environment and does not require any major adjustments in the workshop. The assembler places four profiles at a time on the wedge. Each of these profiles corresponds to an angle allowing the assembly of a frame. When the assembler starts the cycle with a simple push of a button, a cylinder is activated to lock the profiles in position and the cobot applies the glue according to a precise, pre-programmed pattern.

A cycle produced in hidden time (i.e. during production time)

The glue takes between 15 and 20 minutes to dry, allowing the installer to assemble the previous frames. This operation, including cleaning, takes 4 to 5 minutes. The automated glue application therefore saves significant time throughout the entire assembly process.

Successful human-robot cooperation

The cobot handles the gluing operation alone, with minimal human intervention. This is limited to placing the profiles to be glued on the shims, starting the cycle, and supervising the cobot's work. When the fitter presses the button, the cobot, equipped with a cartridge, will apply the glue to the ends of the profiles according to a requested pattern, a precise diagram that can be pre-programmed using the remote display. The solution is controlled solely through this screen. The fitter generally masters this application in just half a day.

Unparalleled adaptability

Emanor has integrated a solution with a considerable advantage: SIMP Production does not need to replace their usual glue cartridge. The cobot adapts perfectly to it. Emanor has also developed an option that allows the cobot to be equipped with a sensor that will alert the fitters when the cartridge needs to be changed. Another option, soon to be available, will be the ability to equip the cobot to alternate the glue color (white, black, or brown).

Increased efficiency, safety, and operator empowerment with cobotic integration

The cobotic gluing solution developed by Emanor has fully achieved the project's core objectives: reducing cycle times, minimizing material usage, and eliminating ergonomic risks for fitters.

Operators are now freed from repetitive and physically demanding tasks, allowing them to focus on higher-value activities such as precise part positioning during assembly. This shift has resulted in a 20% gain in productive time for each operator.

Key outcomes include:

- Enhanced Workplace Safety: The UR5e cobot operates in harmony with human workers, ensuring a secure and collaborative environment.

- Boosted Productivity: The system can glue up to 110 frames per day across multiple parts, representing a 20% increase over manual operations.

- Significant Time Savings: Cleaning time post-assembly has been reduced by 50%, streamlining the overall workflow.

- Operator Ownership: Assemblers have embraced the cobot, actively supervising its operation and ensuring process continuity with minimal interruptions.

- Low Maintenance: The cobot requires virtually no maintenance aside from glue refills, contributing to uninterrupted production.

This successful integration highlights the transformative impact of collaborative robotics in industrial settings—delivering measurable gains in efficiency, safety, and employee satisfaction.

Guillaume Langrené, Leader of EmanorNajbardziej uderzyła mnie łatwość konfiguracji UR10. Doszedłem do tego z bardzo podstawowym doświadczeniem w kodowaniu i nigdy nie doświadczyłem robotyki ani cobots. Ale mieliśmy ramię rozpakowane i uruchomione do poziomu podstawowego w ciągu zaledwie kilku godzin

Skontaktuj się z Universal Robots

Tysiące firm polega na robotach współpracujących, aby...

- Zwiększ produktywność

- Dostosuj się do zmieniającego się popytu na produkty

- Poprawa samopoczucia i retencji pracowników

- Pracownicy z powodu niedoborów siły roboczej

- Universal Robots A/S

- Kateřinská 466/40

- 12000 Praha