Pioneer of collaborative robots introduces SnapWeld Collaborative Robotic Welding, featuring seamless hardware and software integration through the Universal Robots+ product platform.

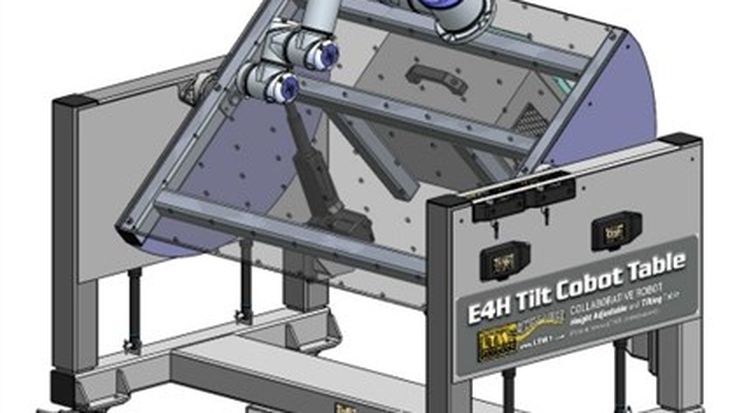

Small job shops struggling with the budget, programming and space requirements of traditional welding robots now have an alternative solution: The newSnapWeld Collaborative Robot Welding packagedeveloped byARC SpecialtiesInc. and Universal Robots is a cobot-assisted, interactive welding system that can be deployed easily and flexibly in existing, manual welding booths, eliminating the need for costly new robotic cells.

“We are getting a lot of requests for integrating Universal Robots in welding booths, so we saw this as a unique opportunity to develop an integrated low-cost system for gas metal arc welding (GMAW) applications that no one else in the market is currently offering,” says John Martin, Vice President of ARC Specialties, a Certified Systems Integrator of UR robots.

The SnapWeld will be shown for the first time at FABTECH in Chicago, November 6-9, 2017, at Universal Robots’ boothB-25094and in interactive demos at ARC Specialties own boothB-35047where attendees can simply grab theUR10 robot armand perform stitch welding by “teaching” the robot the start and stop points, as well as the number and length of the stitch weld. The SnapWeld will move along the start and stop path and weld only during specified stitch areas, reducing robotic programming from hours to minutes.

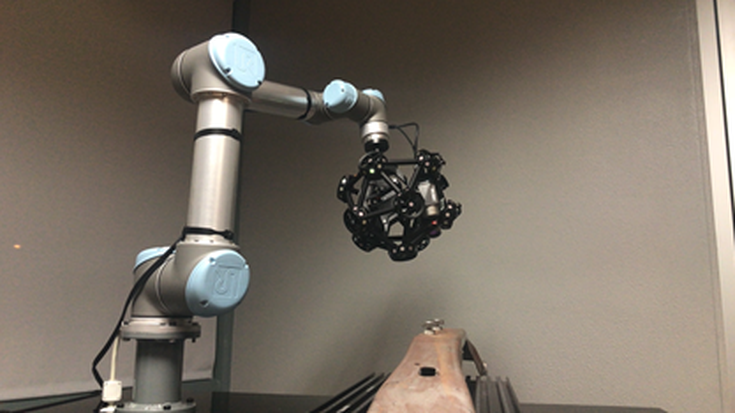

The welding system integrated with the UR robot is comprised of a Profax wire feeder and water cooled torch enabling welds up to 600 amps, with torch bracket, all cables and hose packages included. The simplified programming is enabled by direct software integration into Universal Robots’ own programming environment through theUniversal Robots+ platformthat will allow users to program advanced settings directly on the teach pendant that comes with the UR robot. Settings include features such as wire feed speed and burn back time, gas flow time, and crater fill time with instant feedback on welding volts and amps.

Area Sales Manager of Universal Robots, Manuel Sordo, is excited to include ARC Specialties’ welding package on the UR+ platform which is an online showroom featuring the rapidly expanding ecosystem of plug & play products for UR robots: “This UR+ welding package is the perfect solution for low volume/high mix fabrication shops, allowing operators to manage robot programs and welding parameters on the fly. I look forward to sharing this experience with FABTECH attendees.”