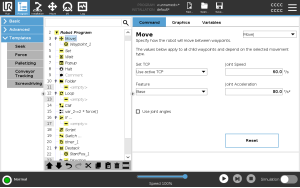

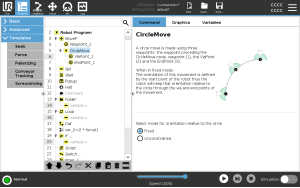

Move

| MoveP |

The MoveP command creates a movement with a constant speed between the waypoints. Blend between waypoints is enabled to ensure constant speed. (See Blending). |

| Add a MoveP command |

|

| Detail |

MoveP moves the tool linearly with constant speed with circular blends, and is intended for some process operations, like gluing or dispensing. The size of the blend radius is by default a shared value between all the waypoints. A smaller value will make the path turn sharper whereas a higher value will make the path smoother. While the robot arm is moving through the waypoints with constant speed, the robot control box cannot wait for either an I/O operation or an operator action. Doing so might stop the robot arm’s motion, or cause a robot stop.

|