Clamp Connection: Disassembly

Unsupported joints can fall, or be dropped, resulting in injury.

-

Support joints while clamps are being removed.

Failure to support the joint/s while clamps are removed can result in damage to equipment.

-

Prevent the joint/s from falling while removing the clamp/s by doing any of the following:

-

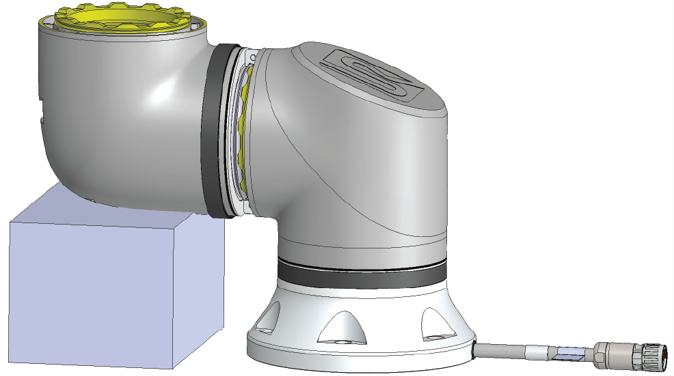

Use something to support underneath the part that is coming off.

-

Disassemble the joint while it is laying down.

-

Support with lifting equipment.

-

Failure to test the old joint before replacing it, can lead to damage to property and/or equipment.

-

Always perform a joint verification test before replacing a joint. See the Joint Verification section in the Service Manual for more information.

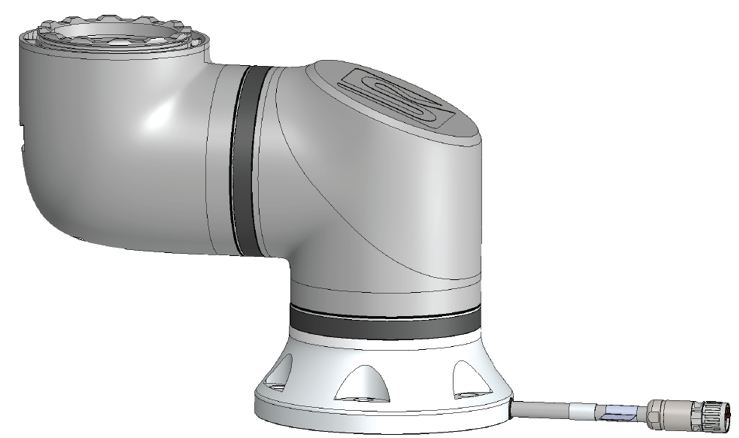

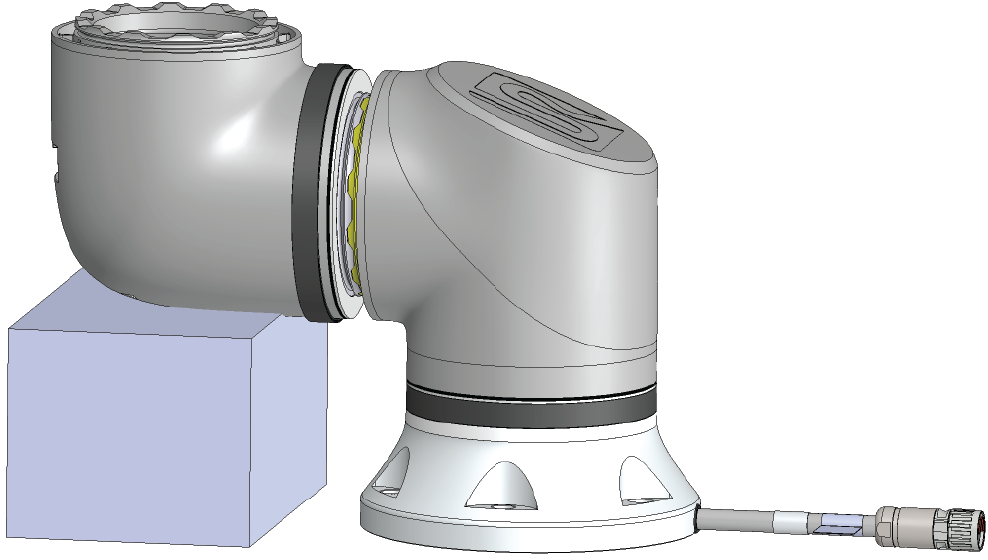

To disassemble:

- Attach the ESD wristband from the spare part package or tool kit to an electrical grounded surface.

- Remove the black flat-ring.

You can use a pair of pointy tweezers or a small flathead screwdriver.

|

1

3

|

2

4

|

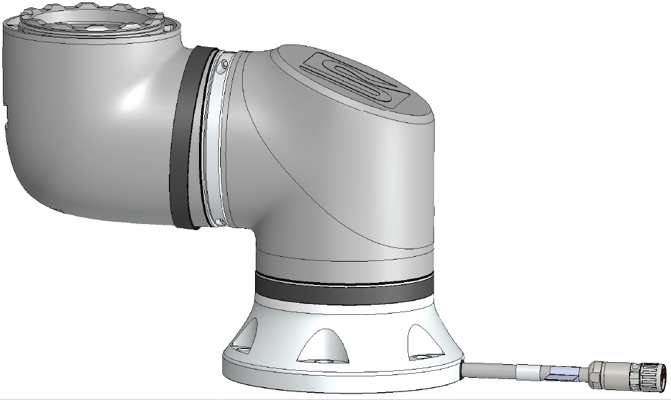

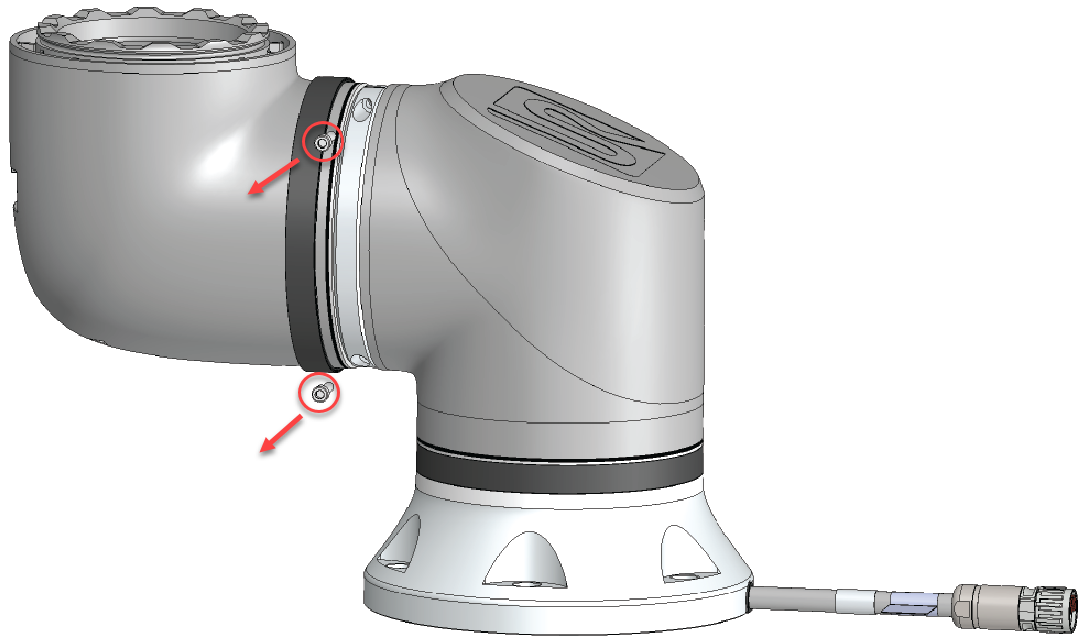

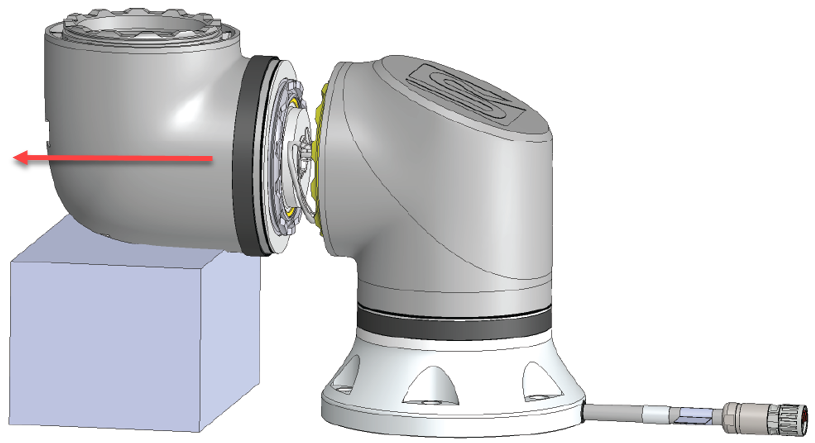

- Remove the screws and the clamp on one side.

|

|

|

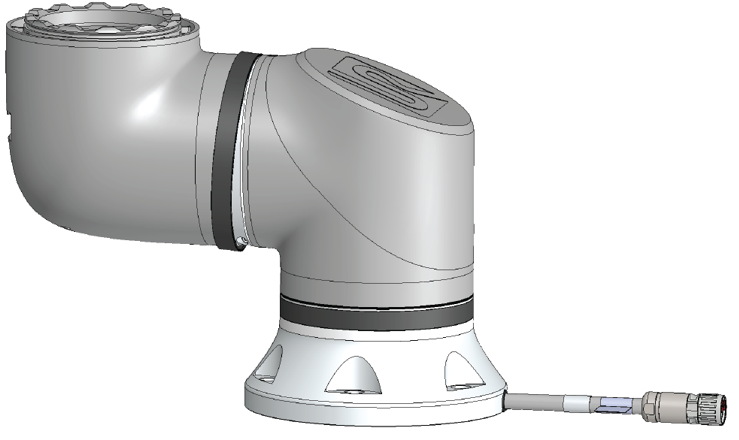

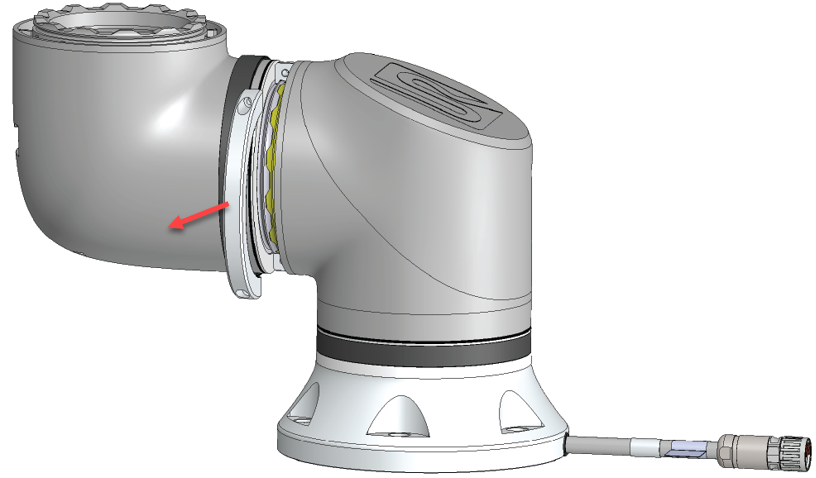

- Support the joint as you remove the second side of the clamp.

|

|

|

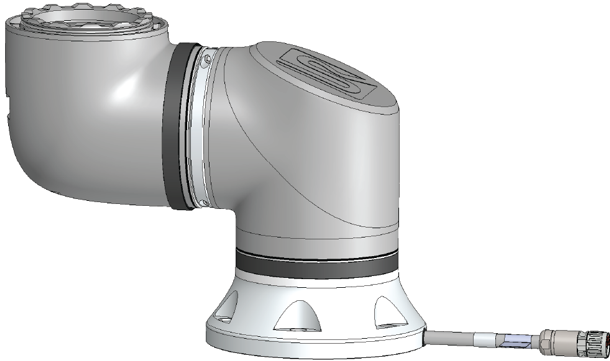

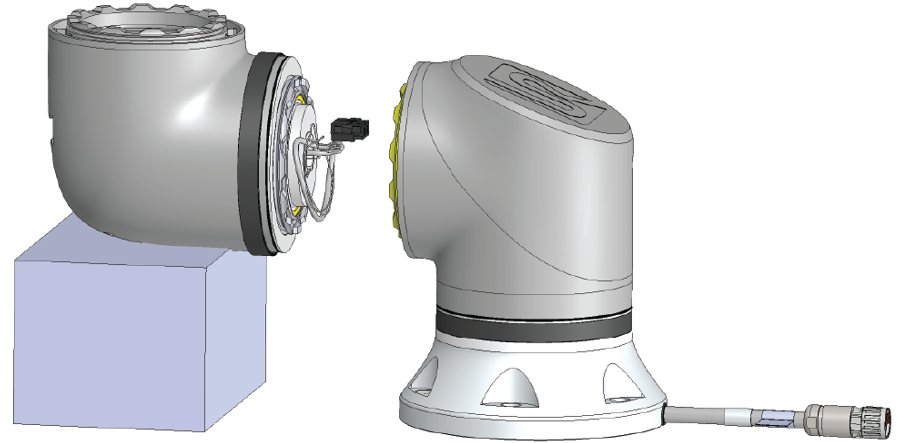

- The joint is now loose and can be removed.

|

|

|

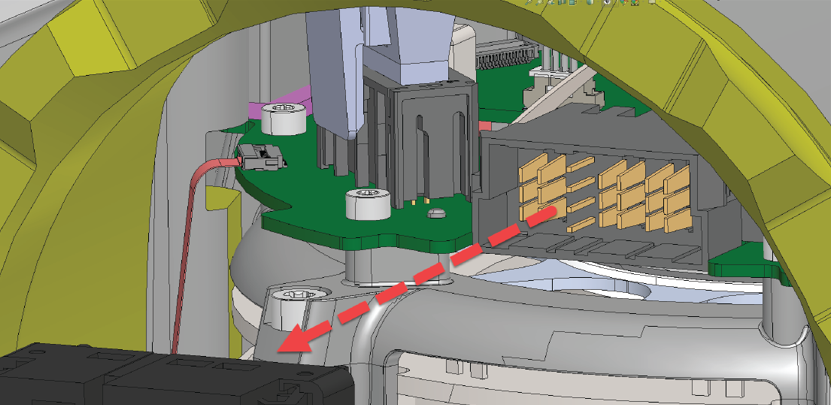

-

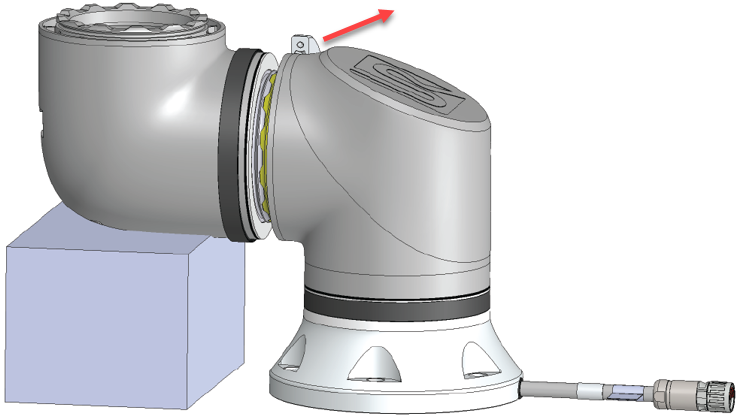

Gently unplug the connector from the PCB on joint.

|

|

|

-

The joint has now been dismounted.