Our industry-leading PolyScope software enables templatization and customization of functions.Supercharge operators and simplify your entire automation journey.

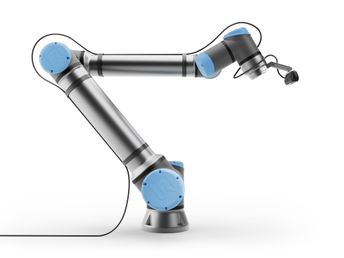

Discover your future-proof platform for robotic automation

Supercharge your workforce with intelligent automation

Automotive businesses today face critical challenges:

- Transforming to produce more complex vehicles

- Reimagining production to deliver on expectations

- Closing widening skills gaps in critical areas

- Balancing new needs with long-term planning

Universal Robots can supercharge your workforce with intelligent automation. So you can empower your people, accelerate performance and unlock ROI everywhere

Our future-proof platform for robotic automation lets you transform the way you operate with greater control, precision and speed. Data insights help you understand operations, smart, customizable cobots empower your workforce and open architecture supports continual innovation.

Unleash the power of your business with a platform designed for performance

Discover how our platform reimagines what is possible for your business across every area of production.

Industry-leading PolyScope software

AI Accelerator

Fast track AI deployment, streamline trouble shooting and enable development of AI-powered apps for UR cobots. Our AI Accelerator tool boosts innovation and productivity everywhere.

myUR

The myUR customer portal enables seamless management of your cobots at global scale, and includes quick access to 24/7 tech support.

UR Academy

UR Academy upskills, empowers and supports your most valuable asset - your people. Helping close the skills gap and elevate job satisfaction.

UR Connect

Unlock increased productivity, eliminate costly downtime, and support more efficient fleet management with UR Connect.

Global SI partnerships

Our 1,200 global partners, distributors, certified system integrators and OEMs help future-proof your innovation through focused collaboration.

UR+ ecosystem

The UR+ ecosystem extends capabilities with over 500 approved products from 310 partner companies, each application designed specifically for UR cobots.

Cobot use cases for automotive manufacturing excellence

Assembly and screwdriving

- Highly accurate screwdriving and assembly at pace and scale

- Outstanding repeatability accuracy down to +/- 0.03 mm (30 microns)

- Reliable precision across even the most complex assembly tasks

Dispensing

- Built-in force sensing for nuanced performance

- Cobots can automate sealants, adhesives, foam-in-place gasketing and lubricant tasks

- Elevate speed, accuracy and quality while reducing waste

Welding

- Deploy cobots MIG/MAG, TIG, Laser, Ultrasonic, Spot/brazing, and plasma and oxy fuel tasks

- Increase efficiency and accuracy across the factory floor to increase time to market

- Enhance overall productivity and throughput

Machine Tending

- Automate loading and unloading of complex tasks

- Deploy cobots for CNC machine tools, injection molders, assembly dial tables & press brakes

- Protect workers, increase operational efficiency and enhance safety

Quality Inspection

- Eliminate the risk of human error and costly recalls with rapid, precision quality testing

- UR-approved cameras for non-destructive 3D measurements speed up testing

- A precision deviation of just ±0.03 mm enables continual excellence & assured repeatability

Palletizing

- Deploy cobots for diverse palletizing tasks to speed performance and increasing flexibility

- Minimize downtime with always-on, rundark capability to increase production output

- Accelerate time to market while enhancing factory floor safety

Curious how cobots can help your business?

Why choose Universal Robots?

Empower your workforce

Unleash the potential of your workforce by empowering them with intelligent cobots Support and enhance critical manufacturing skills. Optimize productivity to help deliver on tighter margins

Get complete control and visibility

Unlock complete command, control and flexibility of performance Accelerate productivity across even the most intricate processes Get complete transparency across operational data plus global 24/7 tech support from our expert team

Unlock ROI everywhere

Drive continual innovation with our advanced tech and open architecture Accelerate time to market and realise ROI more quickly Future-proof your innovation to stay a step ahead

Automotive OEMs

See how we’re reimagining possibilities for automotive OEMs

Ford Motor Company

The challenge: Ford Motor company needed to accelerate production processes and elevate efficiency while empowering and protecting its workers.

How we helped: Our UR10 cobots were deployed to help automate highly complex tasks like greasing camshaft followers, filling engines with oil, and running engine checks for leakage.

Results:

- Decreased repetitive tasks for employees

- Collaborative robots seamlessly integrated into production process

- Significant increases in production speed and efficiency

- Flexible deployment solution is easily moved around shop floor

Toyota Motor Hokkaido

The challenge: Toyota Motor Hokkaido needed to transform to better leverage automation across its factory floor with the aim of significantly enhancing efficiency and streamlining operations.

How we helped: Our UR5e, UR10e & UR16e cobots were deployed at Toyota’s Tomakomai plant to improve its diff-pinion (round gear wheels) loading process.

Results:

- Built a cobot system without a vision camera by utilizing the built-in F/T sensor

- Improved operation rate from 92% to 98%

- Deployment done in-house without external experts

SEAT Componentes

The challenge: SEAT Componentes faced huge challenges in unloading 18,000 machined gears every day at its plant in Spain. This critical task helps ensure quality control and lets the business meet “just in time” delivery.

How we helped: Our UR10e cobots helped fully automate unloading processes to drive increased speed, efficiency and reduced errors. All while protecting and empowering workers

Results:

- Automated unloading of 18,000 gears a day

- Supported communication with AMR vehicles to transport parts

- Reduced errors and improved worker safety

- Enabled 3D print gripper fingers for increased precision

How to guide

Download the guide to learn how Universal Robots supports key automotive tasks, enables global fleet management and connects you to tools like UR Academy or the UR Virtual Factory

We’re different in a way that drives your performance

UR+ ecosystem extends capabilities with over 500 approved products Our AI Accelerator tool enables development of AI-powered applications We offer 2 on-site preventive maintenance visits per cobot/year UR Academy upskills, empowers and supports your engineers and people 310 partner companies deliver automation solutions built specifically for UR cobots We deliver 24/7 availability, remote fleet management, and on-site repairs Our Global SIs ecosystem means we can deploy cobots robots rapidly and strategically Our unmatched depth of expertise is backed by proven track-record of Teradyne

Ready to talk?

Want to know how UR can drive robotic automation for your business?

Fill out the form so one of our experts can get in touch.