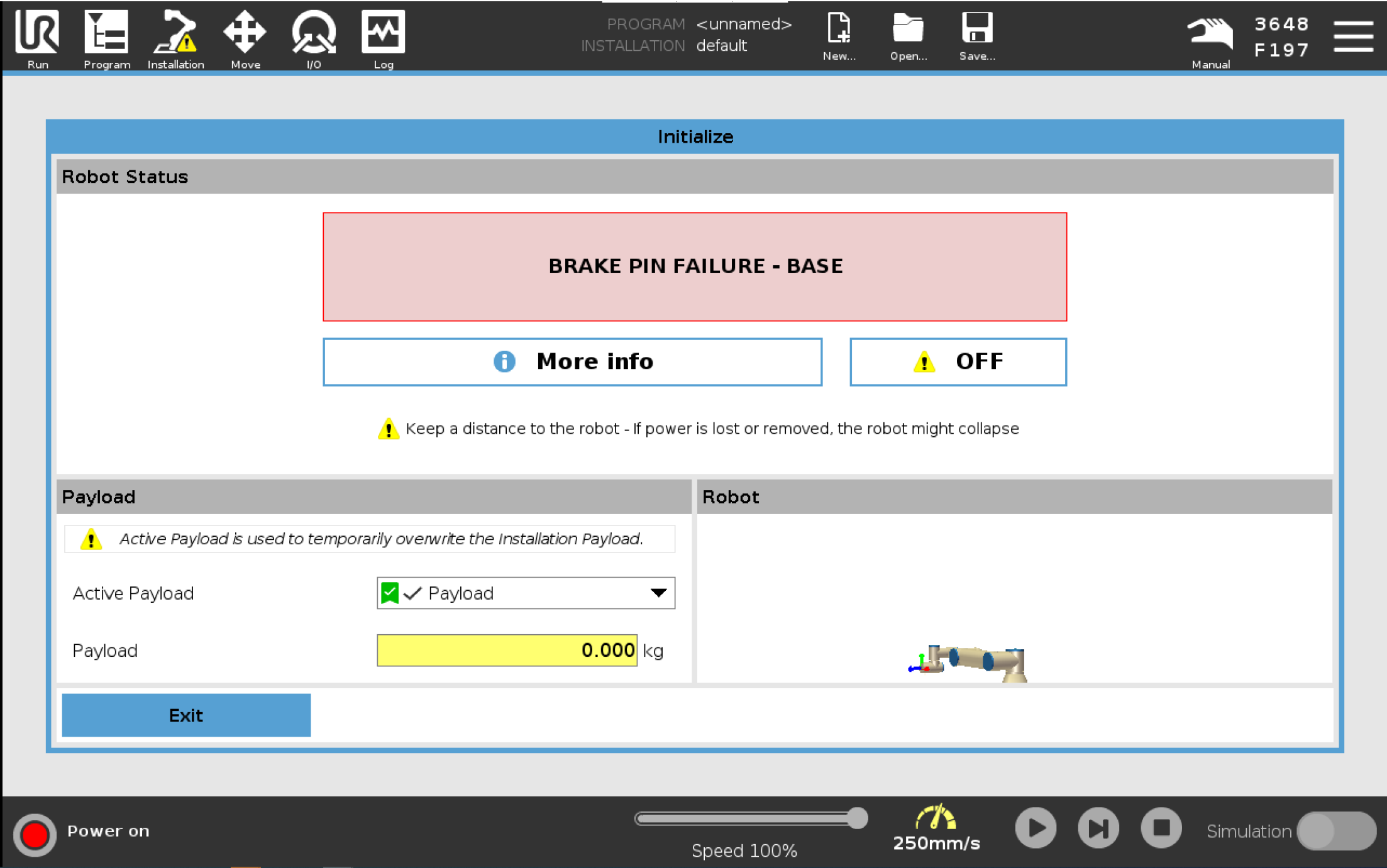

Finding the Faulty Joint

Here the operator can see which joint detected a faulty brake.

An entry will also be added to the log where it can be seen which joint detected a faulty brake.

When the robot is in this state, the dashboard server will not respond normally when queried. It will respond to all requests with information about that the robot encountered a brake system error and a link where further information can be found.

Before powering the robot off in this scenario, the operator needs to ensure that it will not cause any harm to personnel or damage to equipment beneath the robot, as it is likely that the brake will not be engaged, and thus the affected joint will not be able to keep the arm from sliding downwards once the power is removed.

Further operation of the robot will be prevented as the robot will be unable to brake release until the robot has been inspected to ensure the brake is operating properly.

The operator or a service technician need to validate that the brake of the previously reported joint is able to engage before proceeding with the steps in the section Clearing a brake system error.

If the brake is faulty, the brake failure should only be cleared in the case that it is necessary for getting the robot in a position where it can be shipped to a service facility.

To repair the faulty brake system, a service technician should first attempt to replace the brake solenoid in the joint. If that does not resolve the issue, it is likely to be a problem with the friction brake.