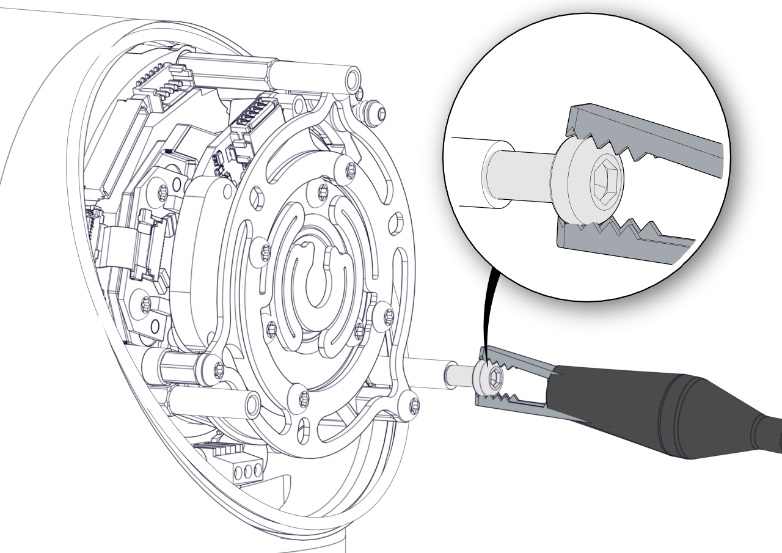

General Guidance to Separate Joint from Counterpart

| Separating joint from counterpart |

Before replacing any components inside the control box, it is important to completely shut it down first. Follow the first three steps in Complete Rebooting Sequence

Exercise caution when handling ESD-sensitive parts. See section 2:

|

|

Disassemble |

If you must disassemble the robot arm, you will need:

Before continuing, read the complete guide in this manual.

|

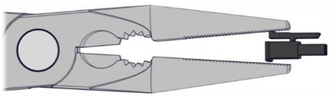

Some connectors have a lock that must be engaged before it is pulled out of the PCB.

|