PROFIsafe

| Description |

The PROFIsafe network protocol (implemented as version 2.6.1) allows the robot to communicate with a safety PLC according to ISO 13849, Cat 3 PLd requirements. The robot transmits safety state information to a safety PLC, then receives information to trigger safety related functions, such as: emergency stop or enter reduced mode. The PROFIsafe interface provides a safe, network-based alternative to connecting wires to the safety IO pins of the robot control box. PROFIsafe is only available on robots that have an enabling license, which you can obtain by contacting your local sales representative, once obtained, the license can be downloaded on myUR. Please refer to Robot Registration and License File for information regarding robot registration and license activation.

|

| Advanced Options |

A status message sent to the safety PLC contains the information in the table below.

|

||||||||||||||||||

| Advanced Options |

|

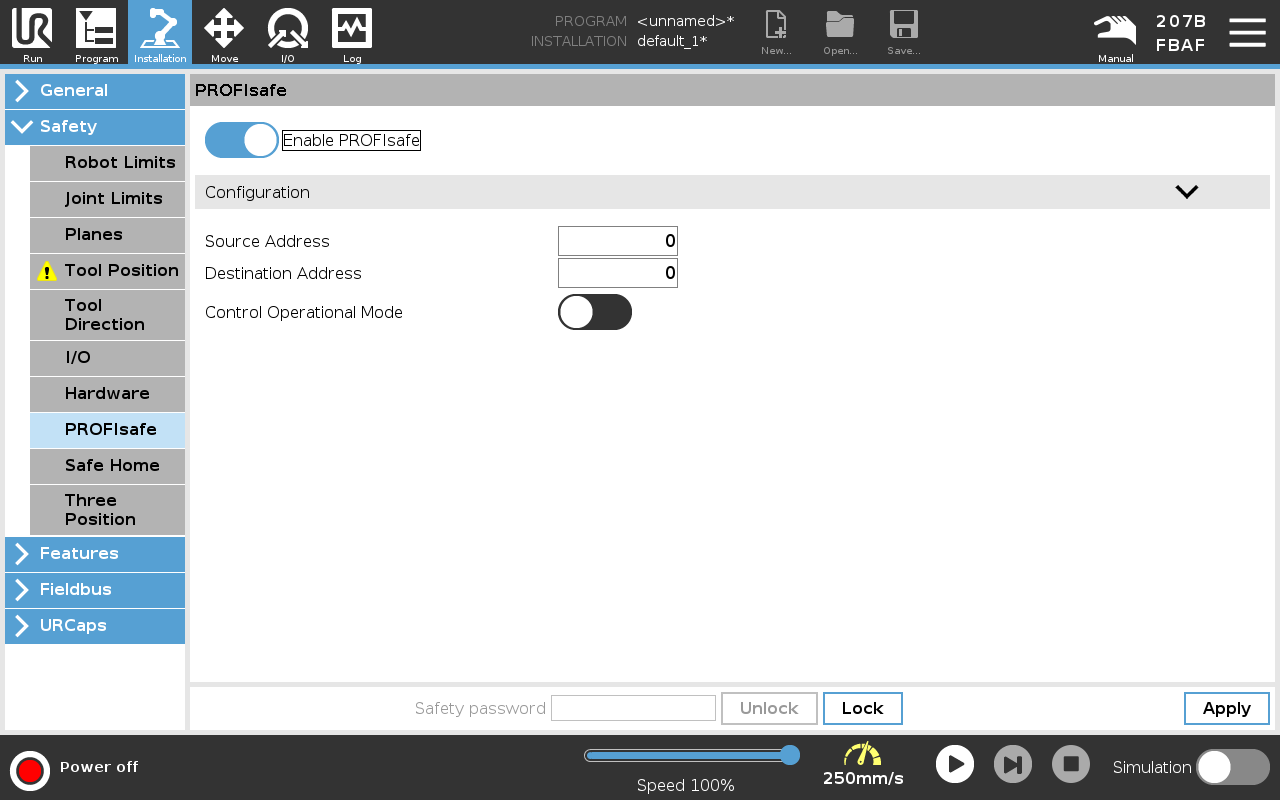

| Configuring PROFIsafe |

Configuring PROFIsafe relates to programming the safety PLC, but requires minimal robot setup.

|

| Enabling PROFIsafe |

The robot is now setup to communicate with a safety PLC. You cannot release the robot's brakes if the PLC is not responding or if it is misconfigured.

|