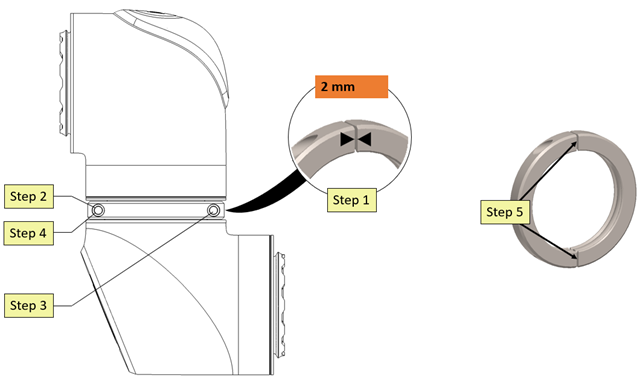

Clamp Connection: Assembly

| Description |

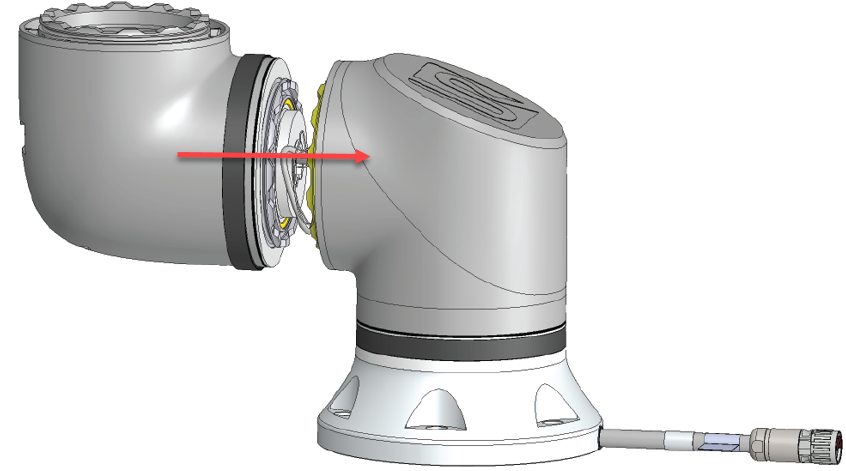

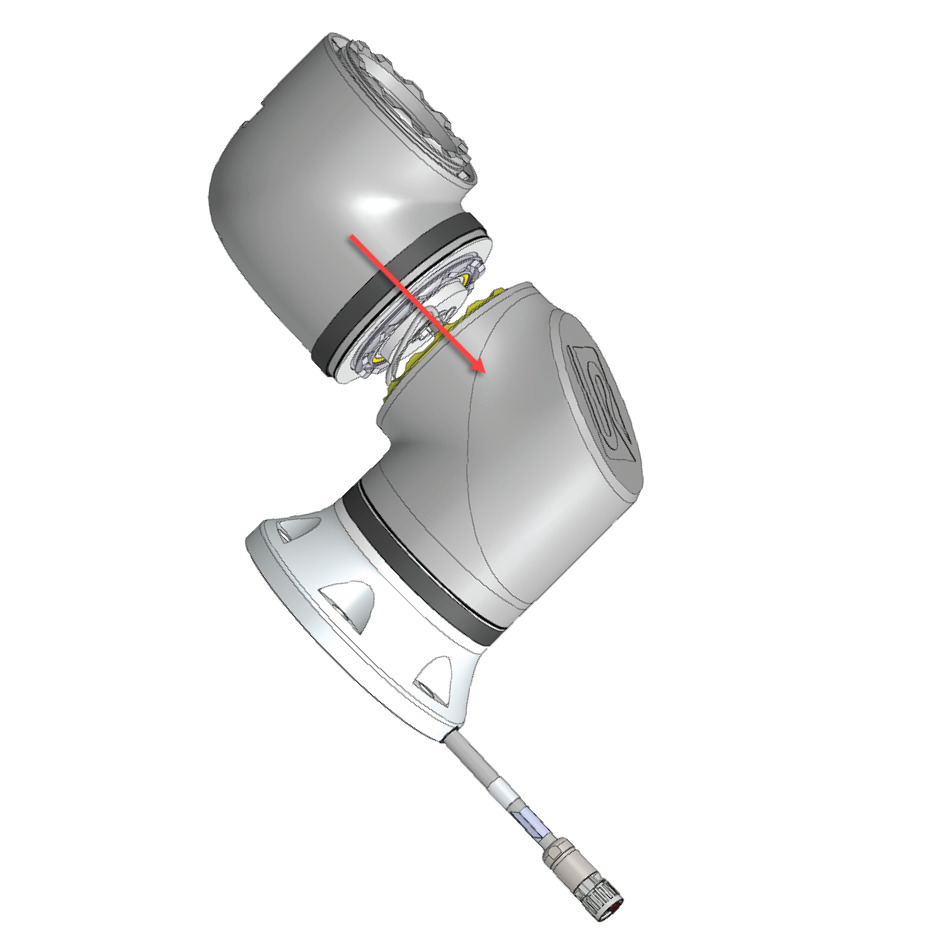

You can now reassemble the clamp connection with the new joint in reverse of the disassembly. However, be aware of the following before you start reassembling the clamp connection. Failure to replace the black flat ring can lower the IP classification and cause damage to property and/or equipment.

Failure to test the new joint after replacement can lead to damage to property and/or equipment.

|

|

|

Improper connection between the joints can lead to damage to property and/or equipment

|

|

|

|

|

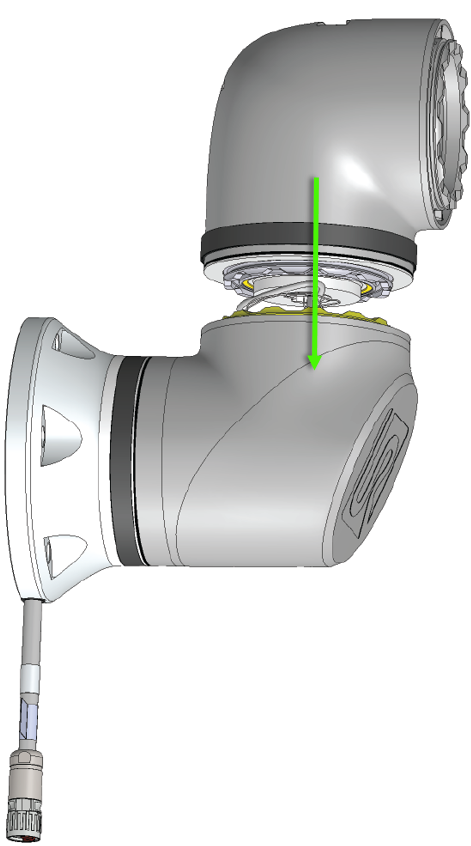

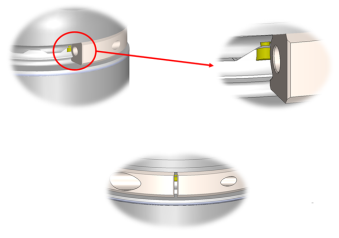

Ensure the screws are inserted in the correct clamp.

When tightening the clamp must be done in steps. Do not exceed recommended torque. To assemble:

|