General Guidance to Separate Joint from Counterpart

Before replacing ANY components inside the Control Box, it is important to completely shut it down first. Follow the first 3 steps in Complete Rebooting Sequence

Exercise caution when handling ESD sensitive parts. See Section 2: Handling ESD-Sensitive Parts

Disassemble:

- Before repairing the robot, make sure the necessary tools are available.

- Service tools with torque tools, ESD Wristband, etc.

- If you must disassemble the Robot Arm you will need:

new flat rings, wear rings, M3 and M4 tap tool("roll tap" or "forming tap") for threads, pre-coated screws, or Loctite.

Before continuing, read the complete guide in this manual.

- Move the robot to an appropriate position for disassembly.

- Shut down the Control Box and remove the main power.

- If necessary, dismount the entire Robot Arm from the work cell and place on a solid surface.

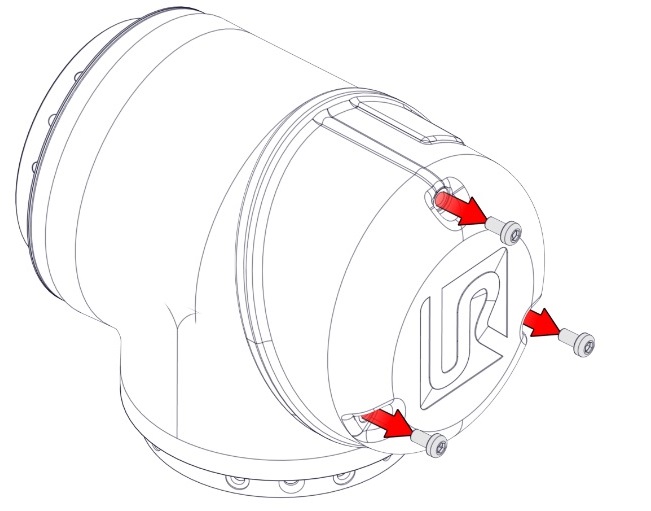

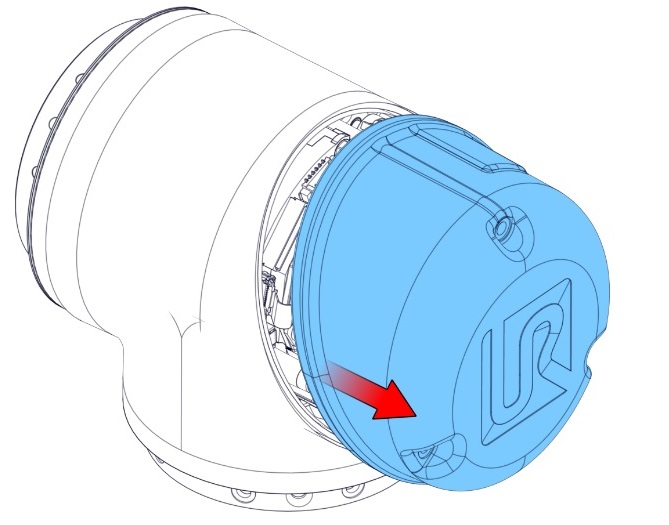

- Remove screws and the blue lid.

|

|

|

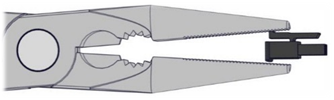

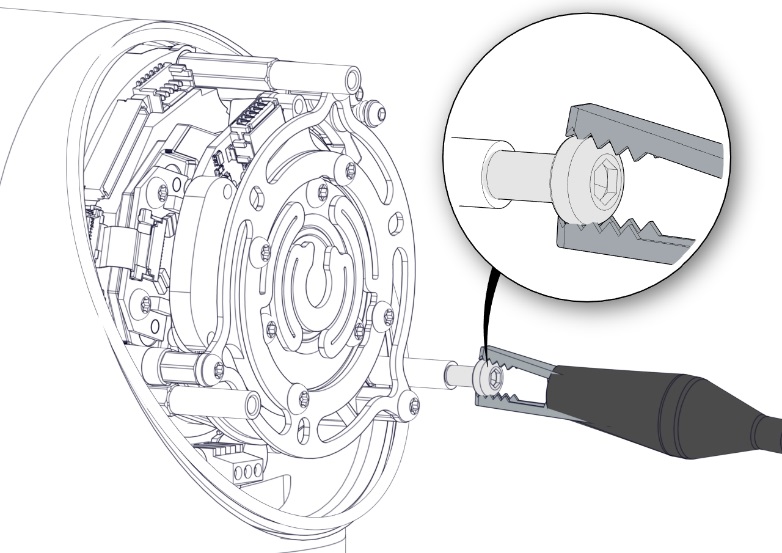

- Now reattach one of the screws, on one of the standoffs and mount the alligator clip on your ESD wristband, as shown below.

|

|

|

Some connectors have a lock that must be engaged before it is pulled out of the printed circuit board.

- Gently unplug the cable connectors without bending the printed circuit board.