Assemble Screw Connection Joint

The assembly is done in reverse of the disassembly. However, a few things must be noted before assembly is begun.

Remove old Loctite residue in the screw holes with a roll tap or forming tap (Size 2 M4 the rest M3) for threads before assembling the joint to get the correct torque on the new screws.

Always use new pre-coated screws when possible. If you must assemble with old screws, carefully clean the screws and add Loctite 243 to the screws before assembly.

Always replace the black flexible flat ring with a new one to maintain the IP classification.

Replace the wear rings if extensive wear or damage is shown

Always use new pre-coated screws when possible. If you must assemble with old screws, carefully clean the screws and add Loctite 243 to the screws before assembly.

Always replace the black flexible flat ring with a new one to maintain the IP classification.

Replace the wear rings if extensive wear or damage is shown

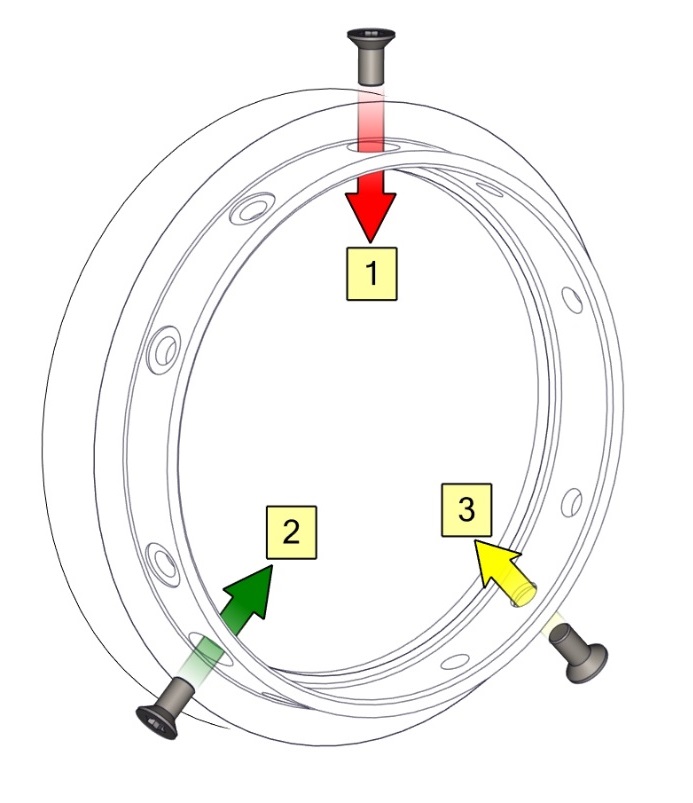

- Orient the joints according to the marks (indicated by red arrows in the image below) and gently push the two joints together.

- Insert and tighten the hex countersunk screws according to the image below. Do not exceed recommended torque.

Example: 1, 2, 3

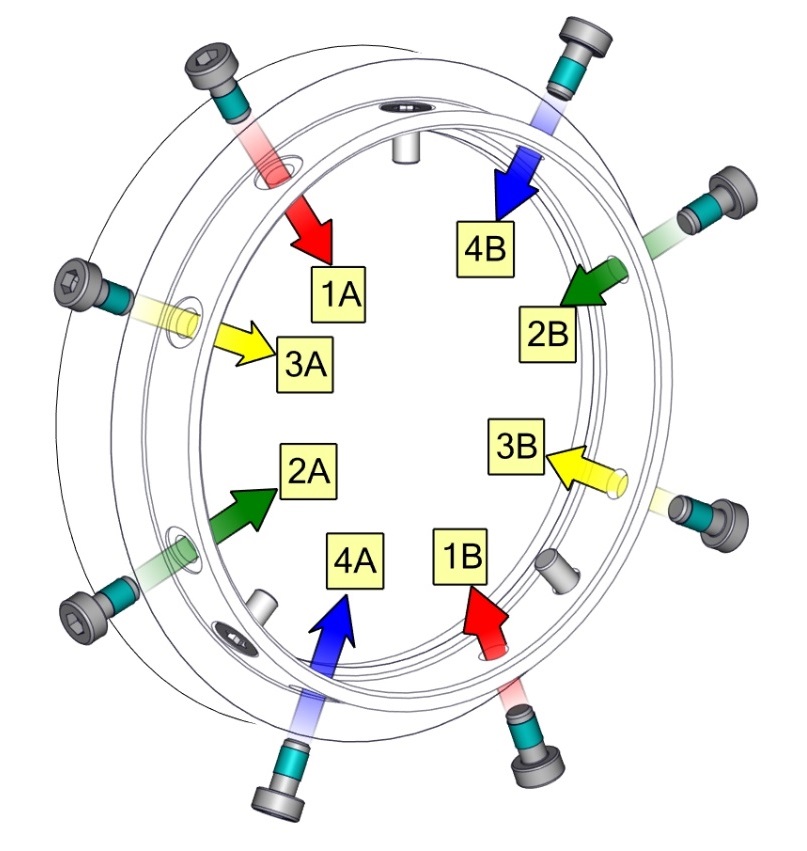

- Insert and tighten the hex screws according to the image below. Do not exceed recommended torque.

Example: 1A, 1B, 2A, 2B etc.