Visual Inspection: Robot arm

Using compressed air to clean the robot arm can damage the robot arm components.

- Never use compressed air to clean the robot arm.

- Move the Robot Arm to ZERO position, if possible.

- Turn off and disconnect the power cable from Control Box.

- Inspect the cable between Control Box and Robot Arm for any damage.

- Check the base mounting bolts are properly tightened.

- Check the tool flange bolts are properly tightened.

- Inspect the flat rings for wear and damage.

- Replace the flat rings if they are worn out or damaged.

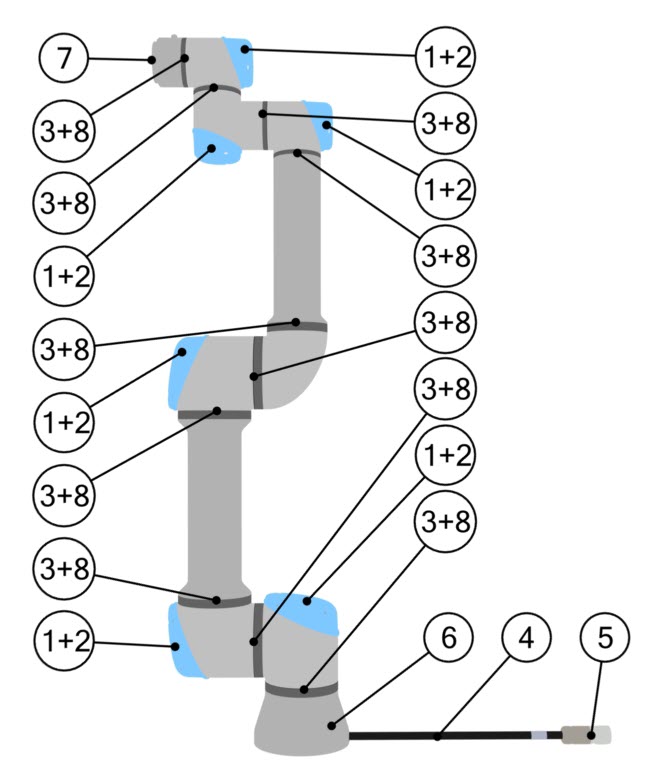

- Inspect the blue lids on all the joints for any cracks or damage.

- Replace the blue lids if they cracked or damaged.

- Inspect the screws used for the blue lids are in place and properly tightened.

- Replace or tighten screws, if necessary.

- Correct the torque value for screws on the blue lids to 0.4 Nm

If any damage is observed on a robot within the warranty period, contact the distributor where the robot was purchased.