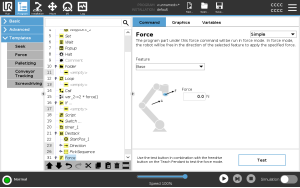

Force

| Description |

Force mode is suited to applications where the actual TCP position along a predefined axis is not important, but instead a desired force along that axis is required. For example, if the robot TCP rolls against a curved surface, pushes or pulls a workpiece.

Force mode also supports applying certain torques around predefined axes. The robot arm attempts to accelerate along that axis, if no obstacles are met in an axis where a non-zero force is set. Although an axis is selected to be compliant, the robot program still tries to move the robot along that axis. However, force control assures that the robot arm still approaches the specified force. Using this function at the same time as Conveyor Tracking and/or Path Offset can lead to program conflict.

If there is a Force node inside an

If, ElseIf or Loop, and the Check Expression Continuously option is selected, you can add an end_force_mode() script at the end of the expression to exit force control. |

|

| Speed limits |

Maximum Cartesian speed can be set for compliant axes. The robot moves at this speed in force control, as long as it does not come into contact with an object.

|