First Boot

| Description |

The first boot is the initial sequence of actions you can take with the robot after assembly.

While the robot arm is powered on you can use Freedrive to move the robot. The robot arm requires ample space to operate freely. |

|

Failure to verify the payload and installation before starting up the robot arm can lead to injury to personnel and/or property damage.

Incorrect payload and installation settings prevent the robot arm and Control Box functioning correctly.

Starting up the robot in lower temperatures can result in lower performance, or stops, due to temperature dependent oil and grease viscosity.

|

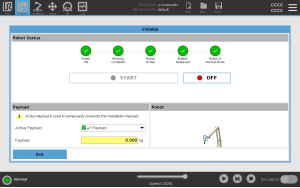

Starting your robot

| To start the robot |

Start up disengages the braking system in the robot arm, allowing you to use freedrive.

Robot arm start up is accompanied by sound and slight movements as joint brakes are released.

|

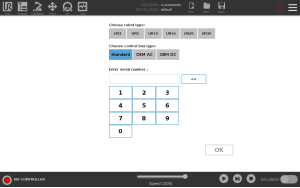

Inserting the Serial Number

| To insert the serial number |

When you install your robot for the first time, you need to configure serial number on the control box to match the robot arm. This procedure is also required when you re-install the software on the control box, such as when receiving a software update. |

|

|

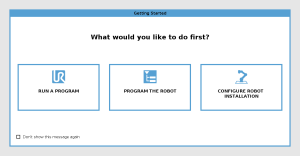

When you boot the robot for the first time, please follow these steps:

|

Initializing the Robot Arm

Turning the Control Box On/Off

Powering Down the Robot

| To power down the robot arm |

Unexpected start-up and/or movement can lead to injury

|