Clamp Connection: Disassembly

| Description |

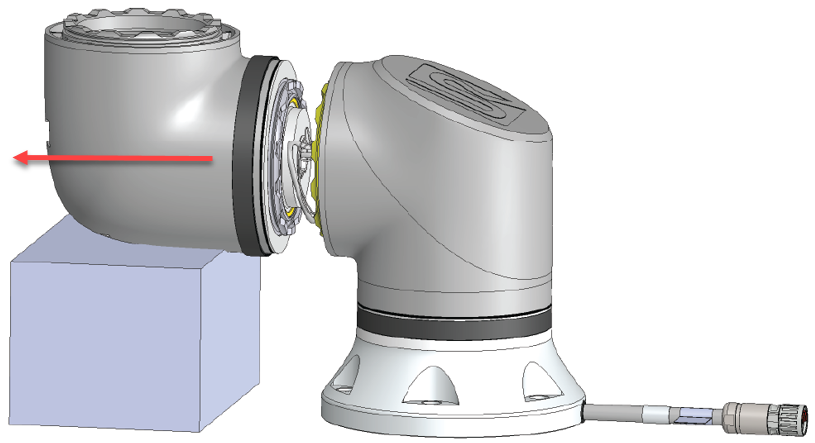

Unsupported joints can fall, or be dropped, resulting in injury.

Failure to support the joint/s while clamps are removed can result in damage to equipment.

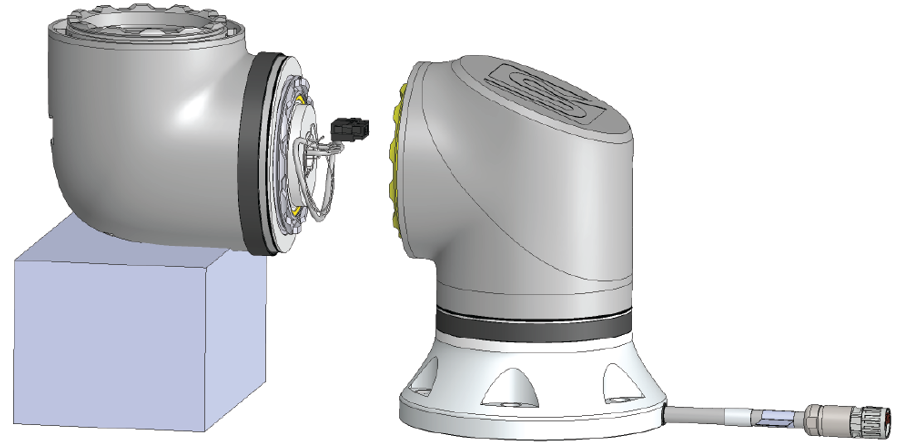

Failure to test the old joint before replacing it, can lead to damage to property and/or equipment.

|

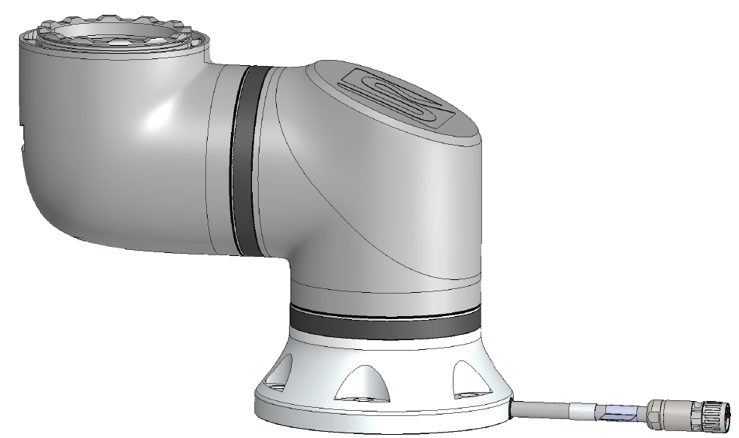

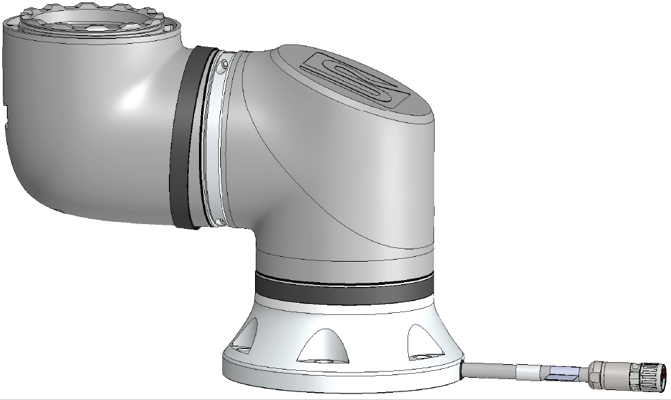

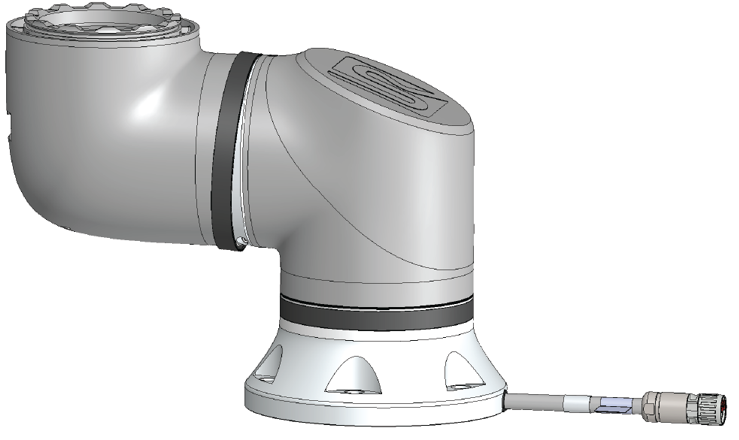

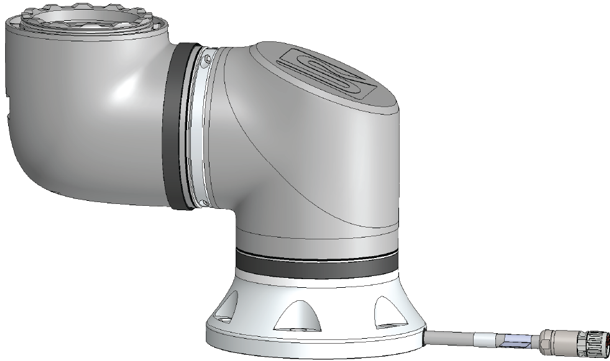

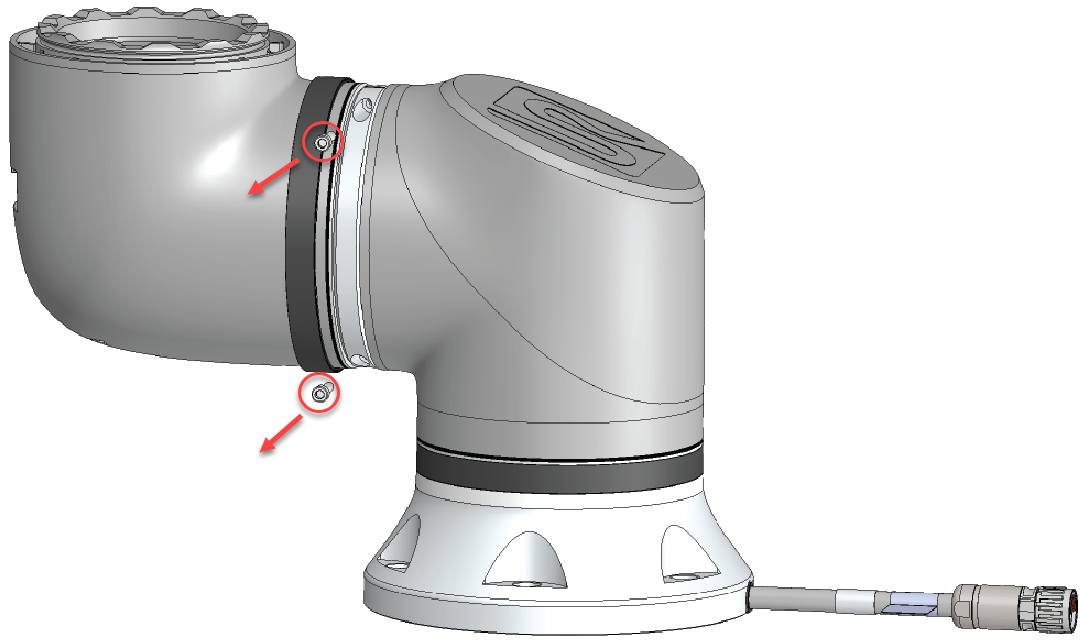

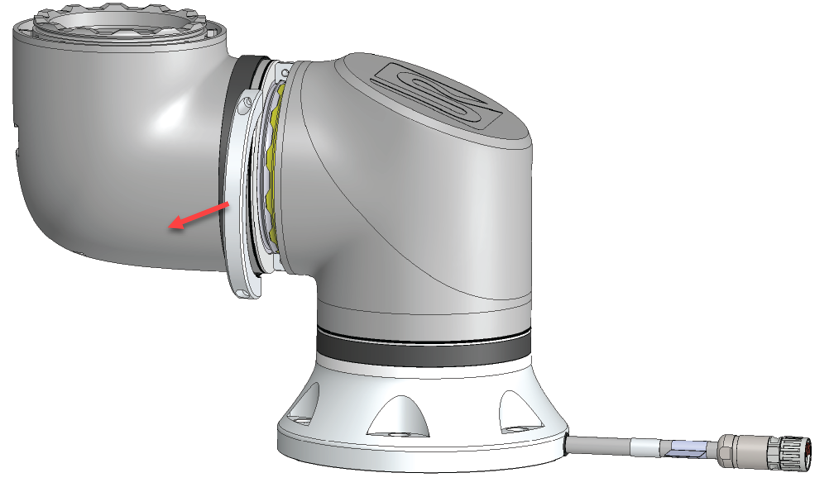

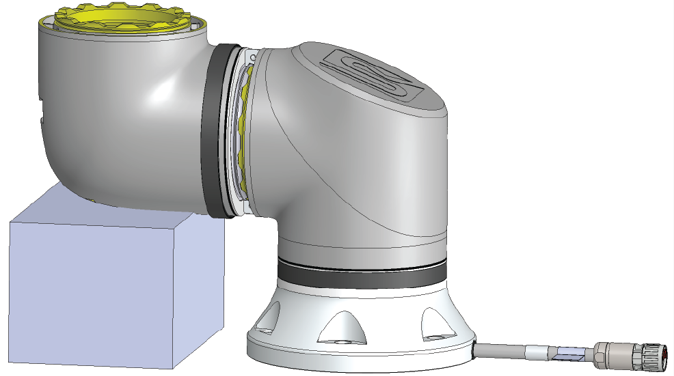

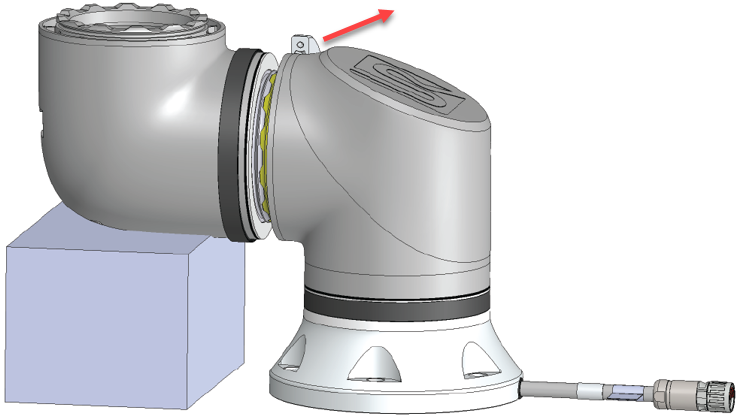

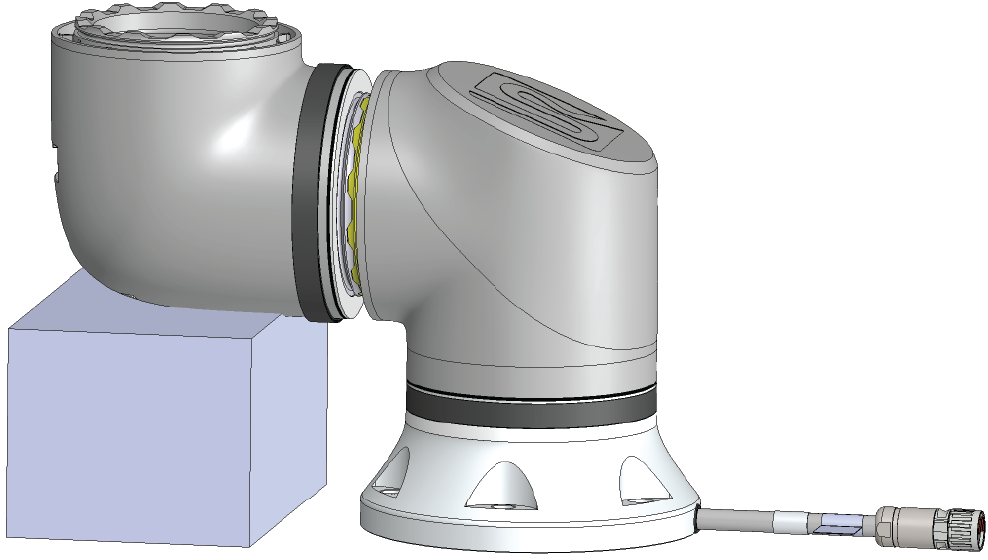

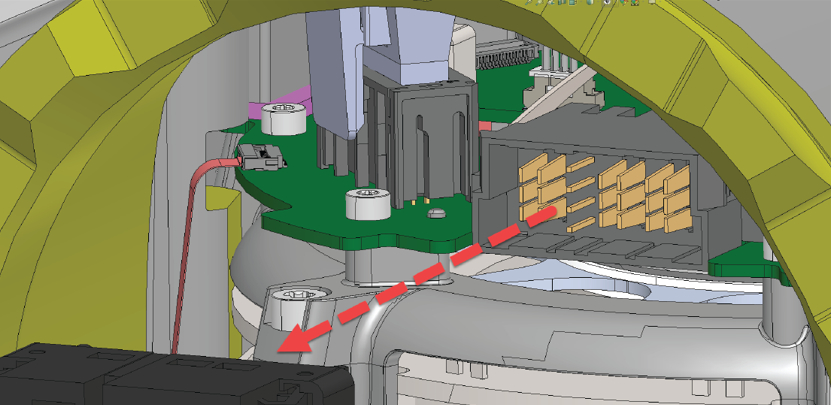

| To Disassemble |

|

|

|

|