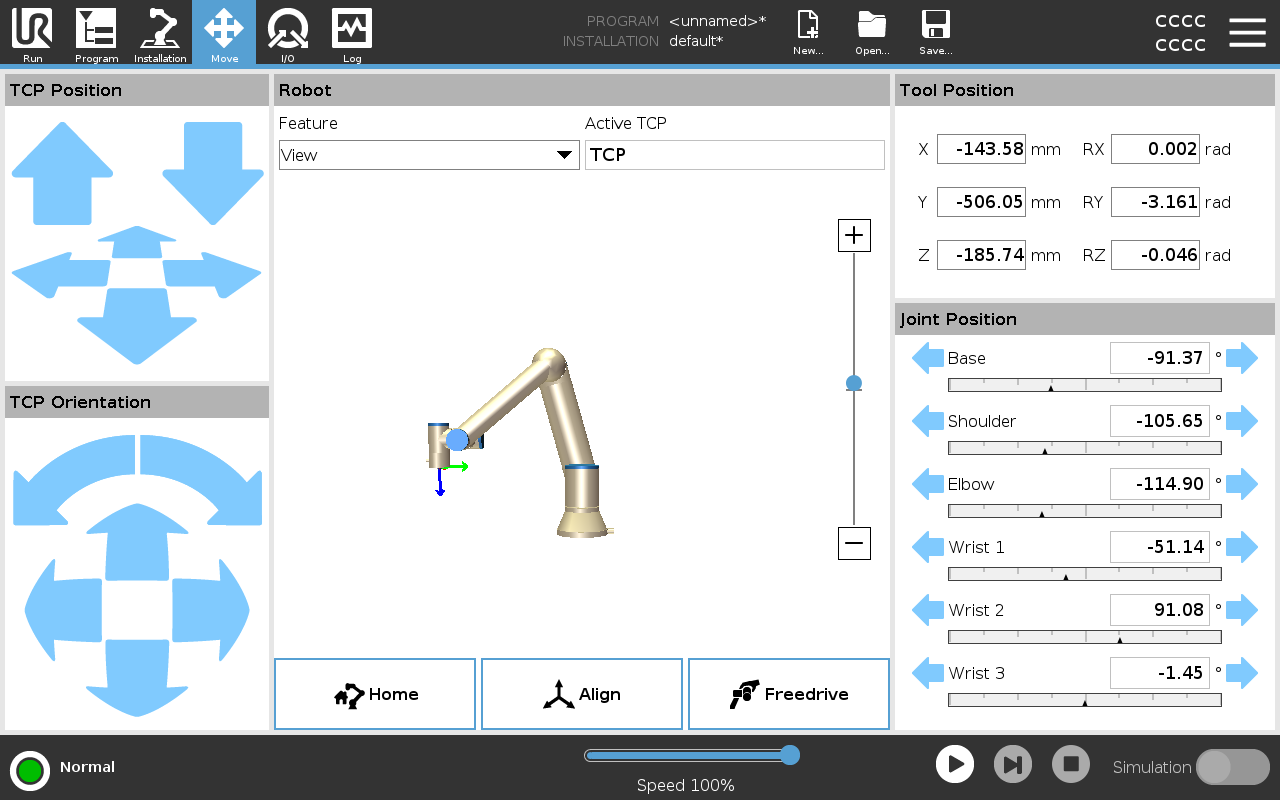

Move Tab

| Description |

Use the Move Tab screen to move (jog) the robot arm directly, either by translating/rotating the robot tool, or by moving robot joints individually.

|

| Active TCP |

In the Robot field, under Active TCP, the name of the current active Tool Center Point (TCP) is displayed.

|

| Freedrive |

The on-screen Freedrive button allows the Robot Arm to be pulled into desired positions/poses.

|

| Align |

The Align button allows the Z axis of the active TCP to align to a selected feature.

|

| Using Freedrive in the Move tab |

The Freedrive button shall only be used in applications if allowed by the risk assessment. Failure to correctly configure the mounting setting can result in unwanted robot arm movement when you use the Freedrive button.

Failure to correctly configure the installation settings, can increase the risk of the robot arm falling during Freedrive, due to payload errors.

|