Handling ESD-Sensitive Parts

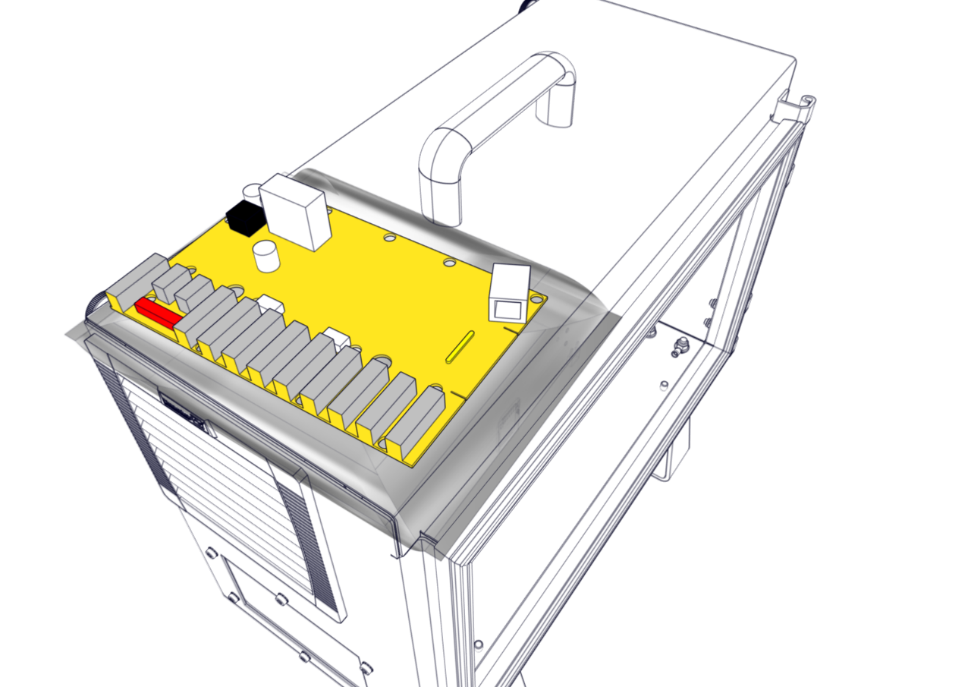

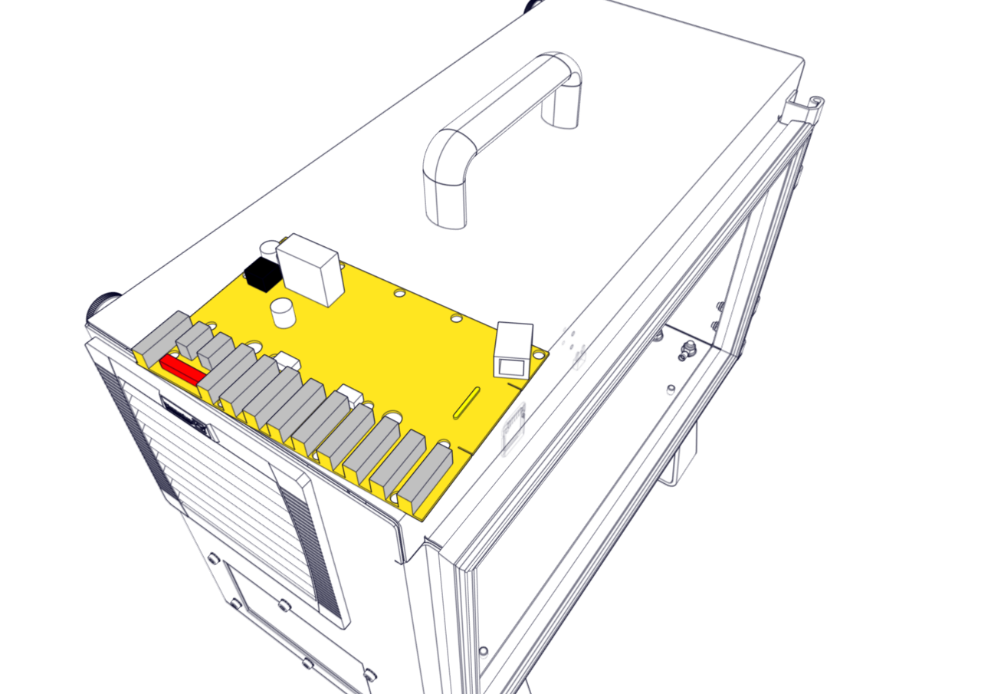

To prevent damage to ESD-sensitive parts i.e. Printed Circuit Board, follow the instructions below in addition to all the usual precautions, such as turning off the power before removing the circuit boards. See section Complete Rebooting Sequence

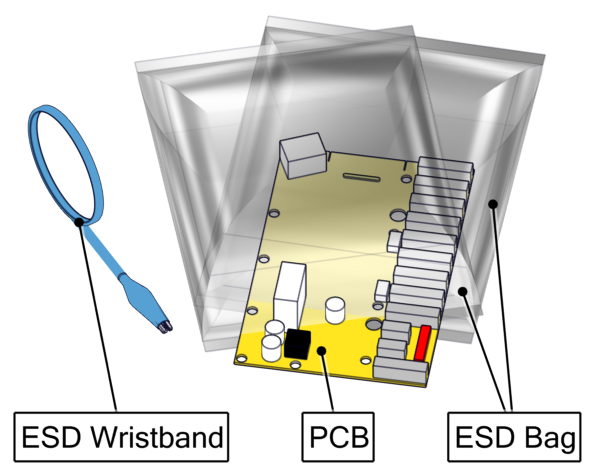

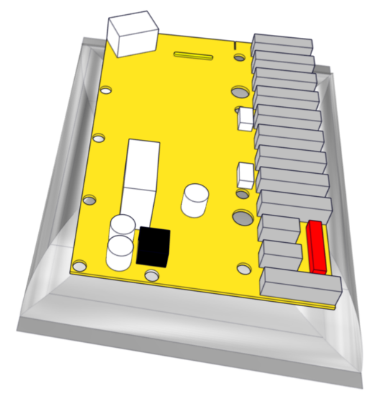

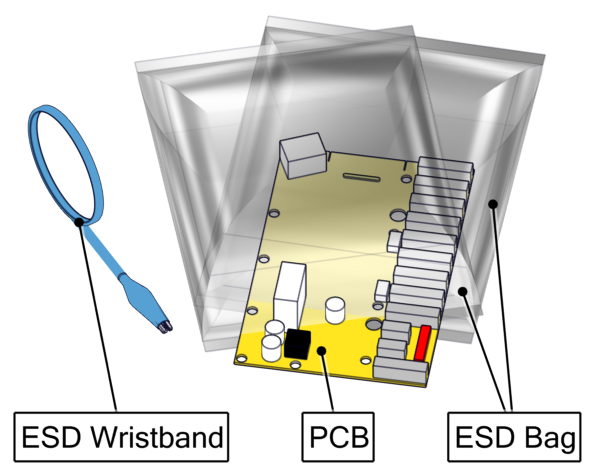

Be sure you have intact ESD Wristband and a spare ESD bag before replacing any ESD-sensitive parts.

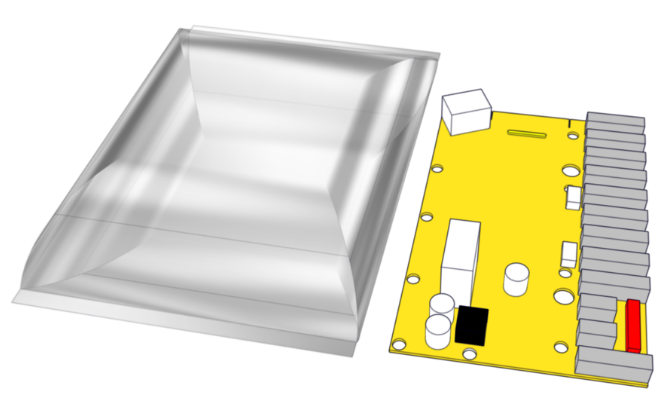

Keep the ESD-sensitive part in its original shipping container (a special "ESD bag") until the part is ready to be installed.

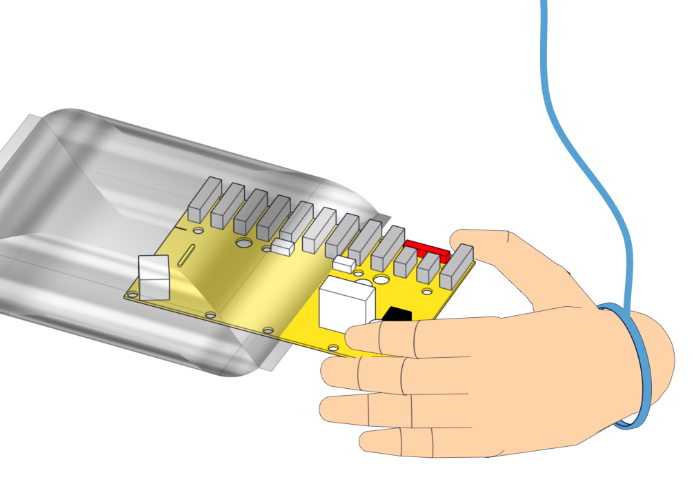

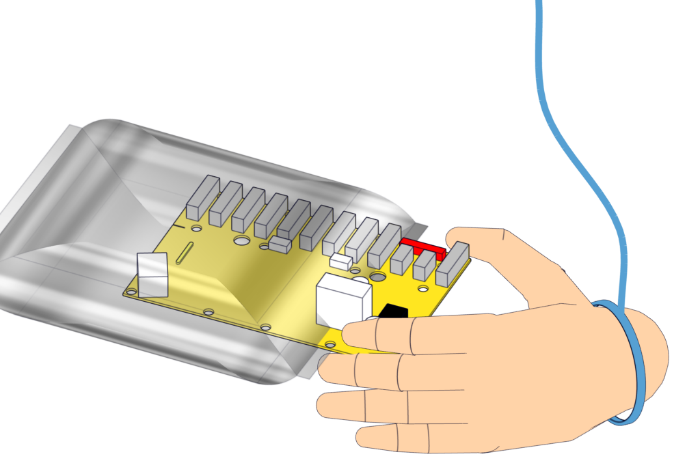

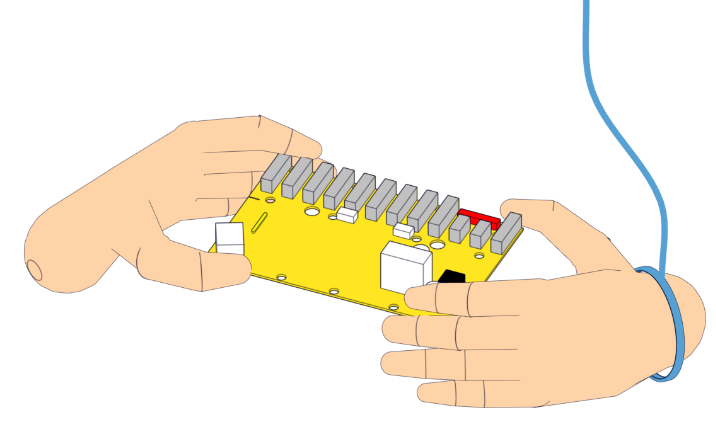

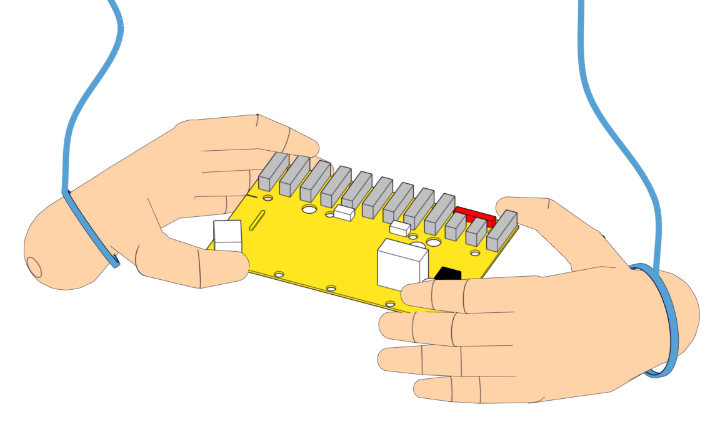

Put the ESD wristband on your wrist. Connect the wristband to the system ground point.

It discharges any static electricity in your body to ground.

Replacing an ESD-sensitive part in a safe way is important to avoid damage to the part. It is important to take precautions when handling an ESD-sensitive part.

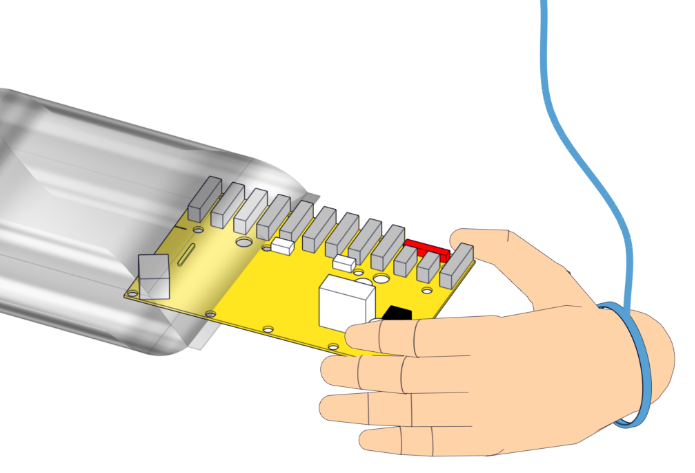

Hold the ESD-sensitive part by its edges. Do not touch its pins or hold directly on any exposed prints.

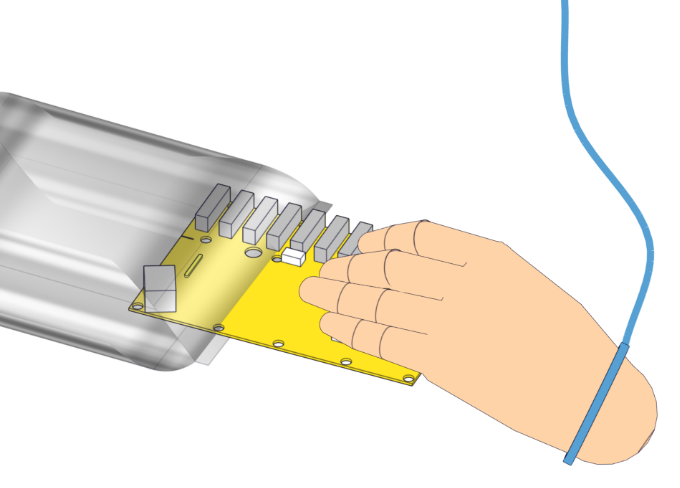

First place the OLD part in the spare ESD bag, then take out the NEW part of the ESD bag.

Do not place the ESD-sensitive part on nonconductive material or on metal tables/surfaces. If you must put down the ESD-sensitive part for any reason, then first place it into the ESD bag.

Machine covers and metal tables/surfaces are electrical grounds. They increase the risk of damage because they make a discharge path from your body through the ESD-sensitive part. (Large metal objects can be discharge paths without being grounded.)

If passing an ESD-sensitive part to another person, ensure both are wearing ESD wristband and the ESD wristband is attached to the system grounding point.

Be extra careful in working with ESD-sensitive parts when cold-weather and heating is used, because low humidity increases static electricity.