Replacing Robot Arm Joints

| Description |

The replacement procedure applies to all joints, tool mounting brackets, and tool mounting brackets with force/torque sensor. For detailed information on how to safely perform service-related operations and troubleshooting, refer to the Universal Robots service manuals at universal-robots.com/download. For direct support, create a support ticket on our customer portal, MyUR @ https://myur.universal-robots.com/. |

| Warnings |

Unsupported joints can fall, or be dropped, resulting in injury

Failure to support the joint/s while screws are removed can result in damage to equipment.

Failure to test the new joint after replacement can lead to damage to property and/or equipment.

|

|

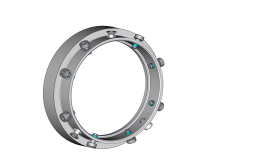

Connections |

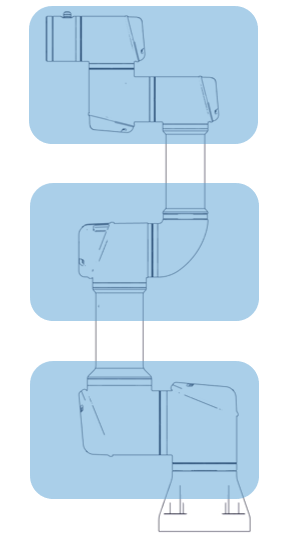

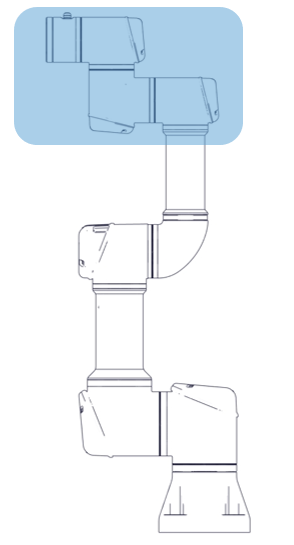

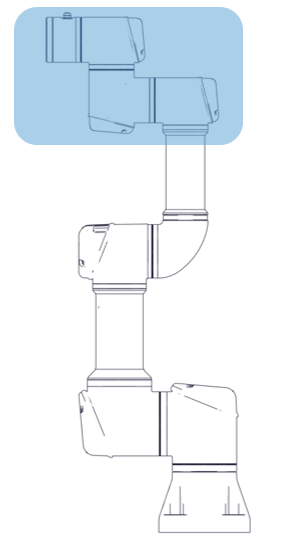

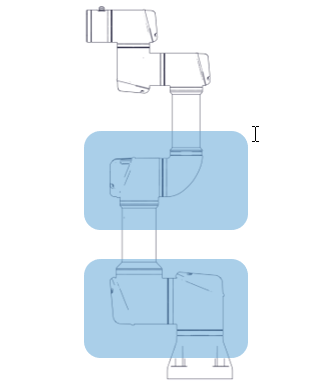

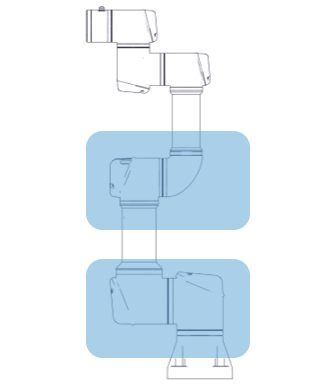

There are two different ways the joints are assembled.

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Robot Joints |

|

|||||||||||||||