Securing the Tool

| Description |

The tool or workpiece is mounted to the tool output flange (ISO 9409-1-80-6-M8) at the tip of the robot.

Dimensions and hole pattern of the tool. All measurements are in millimeters. |

| Tool flange |

The tool output flange (ISO 9409-1) is where the tool is mounted at the tip of the robot. It is recommended to use a radially slotted hole for the positioning pin to avoid over-constraining, while keeping precise position. |

|

|

Very long M8 bolts can press against the bottom of the tool flange and short circuit the robot.

|

|

|

Failure to tighten bolts properly cause injury due to loss of the adapter flange and/or end effector.

|

| Tool Flange Accessories |

The tool flange can require an accessory element to facilitate connection with tools. Depending on the tool, you can use the following tool flange accessories: Tool Cable Adapter (see Tool Flange Adapter).

|

|

The tool flange adapter is a mechanical accessory for the tool flange that reduces the tool flange screw pattern from EN ISO-9409-1-80-6-M8 to EN ISO 9409-1-50-4-M6. (see Maximum Payload) |

|

|

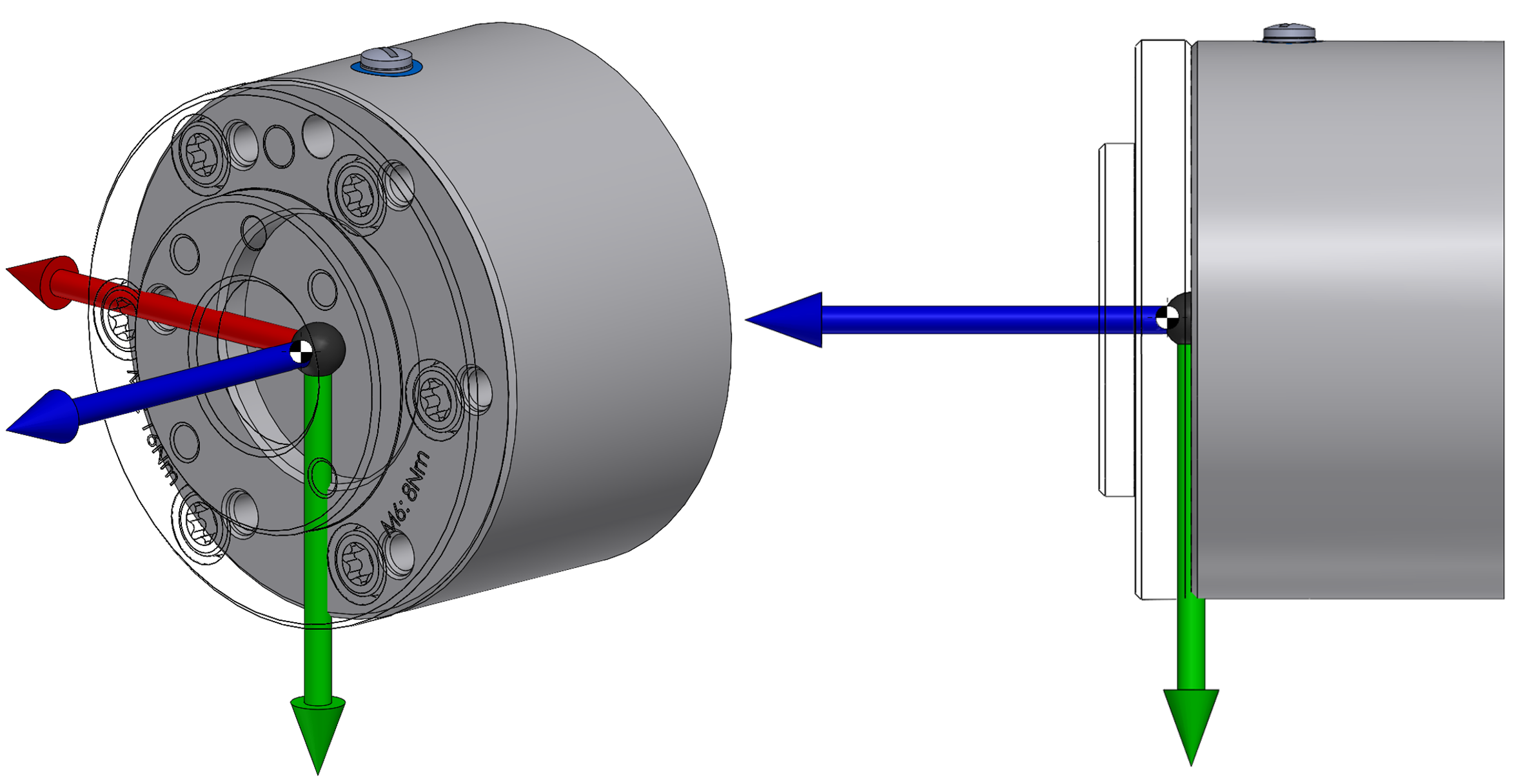

Coordinate system and center of mass.

|

|

|

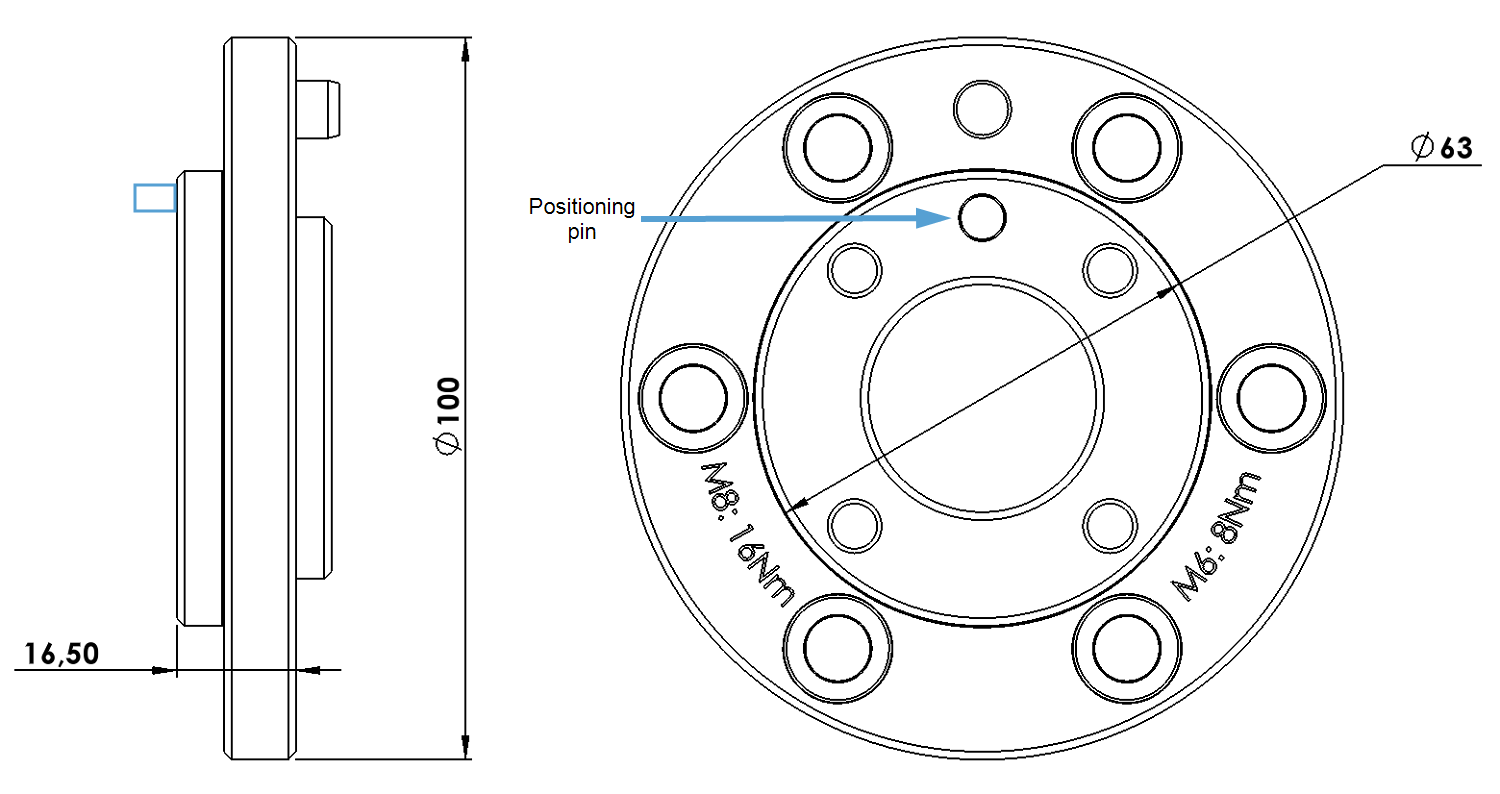

Dimensions and screw-tightening moments of the tool flange adapter. |

|

|

The tool flange adapter, including six M8 screws and a positioning pin, has the listed mechanical properties:

Observe particular caution when using the tool adapter. Failure to attach the end effector properly can cause injury due to losing the end effector.

|