Securing the Robot Arm

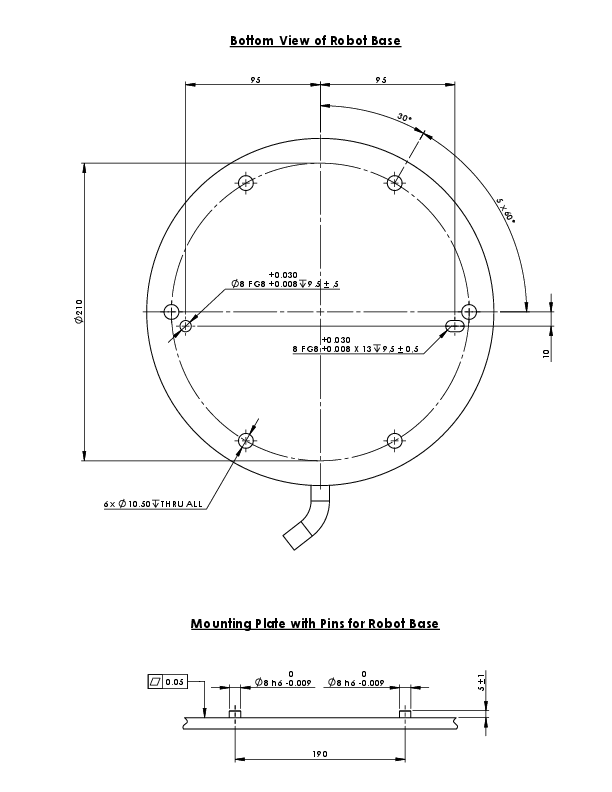

| Description |

Dimensions and hole pattern for mounting the robot. |

| To power down the robot arm |

Unexpected start-up and/or movement can lead to injury

|

| To secure the robot arm |

|

| Dimensioning the Stand |

The structure (stand) on which the robot arm is mounted is a crucial part of the robot installation. The stand must be sturdy and free of any vibrations from external sources.

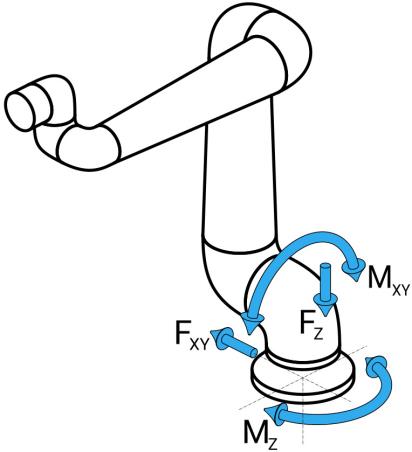

Each robot joint produces a torque that moves and stops the robot arm. During normal uninterrupted operation and during stopping motion, the joint torques are transferred to the robot stand as:

Definition of force and moment at the base flange. |

|

Dimensioning the Stand |

The magnitude of the loads depends on robot model, program and multiple other factors. Dimensioning of the stand shall account for the loads that the robot arm generates during normal uninterrupted operation and during category 0, 1 and 2 stopping motion. During stopping motion, the joints are allowed to exceed the maximum nominal operating torque. The load during stopping motion is independent of the stop category type. The values stated in the following tables are maximum nominal loads in worst-case movements multiplied with a safety factor of 2.5. The actual loads will not exceed these values.

Maximum joint torques during category 0, 1 and 2 stops.

Maximum joint torques during normal operation. The normal operating loads can generally be reduced by lowering the acceleration limits of the joints. Actual operating loads are dependent on the application and robot program. You can use URSim to evaluate the expected loads in your specific application. |

|

Dimensioning the Stand |

Users have the option to incorporate added safety margins, factoring in the following design considerations:

|