Safety I/O

| Table

|

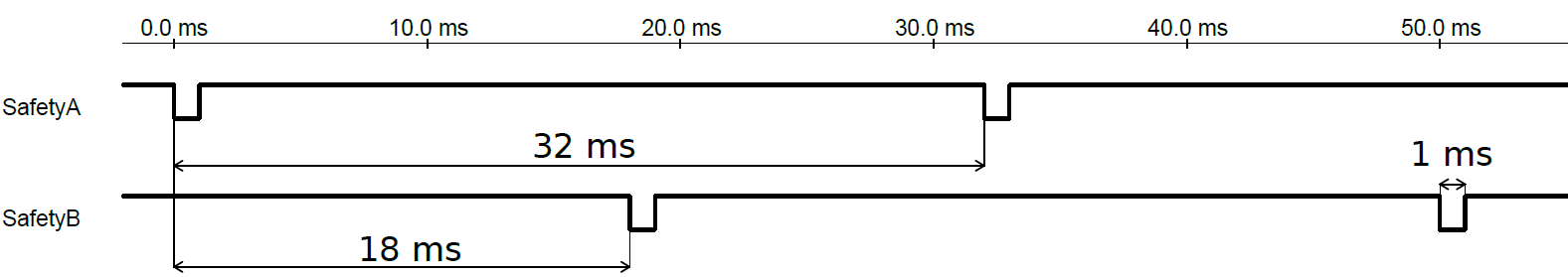

The functional difference is shown below.

|

| Safety caution

|

Use the configurable I/O to set up additional safety I/O functionality, e.g. Emergency Stop Output. Configuring a set of configurable I/O for safety functions are done through the GUI, (see part Part II PolyScope Manual). Failure to verify and test the safety functions regularly can lead to hazardous situations.

|

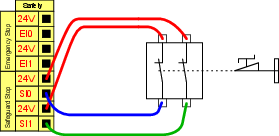

| Default safety configuration |

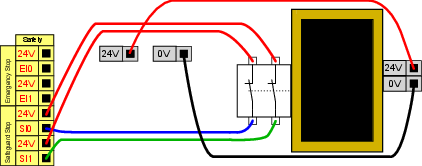

The robot is delivered with a default configuration, which enables operation without any additional safety equipment (see illustration below).

|

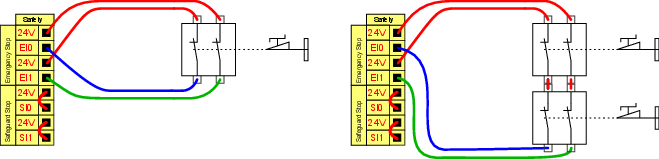

| Connecting emergency stop buttons |

Most applications require one or more extra emergency stop buttons. The illustration below shows how one or more emergency stop buttons can be connected.

|

| Safeguard stop with automatic resume |

This configuration is only intended for applications where the operator cannot go through the door and close it behind him. The configurable I/O is used to setup a reset button outside the door to reactivate robot motion. The robot resumes movement automatically when the signal is re-established. Do not use this configuration if signal can be re-established from the inside of the safety perimeter.

|

|

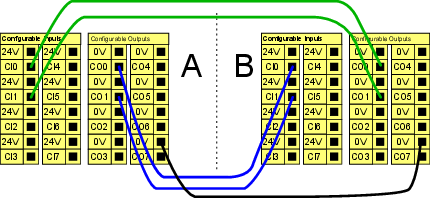

Safeguard Stop with reset button |

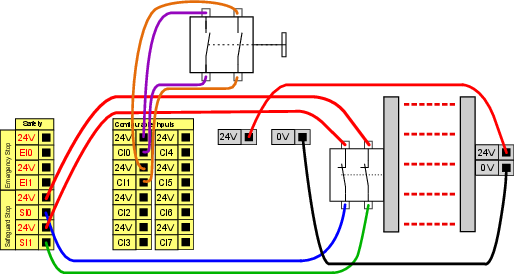

If the safeguard interface is used to interact with a light curtain, a reset outside the safety perimeter is required. The reset button must be a two channel type. In this example the I/O configured for reset is CI0-CI1 (see below).

|