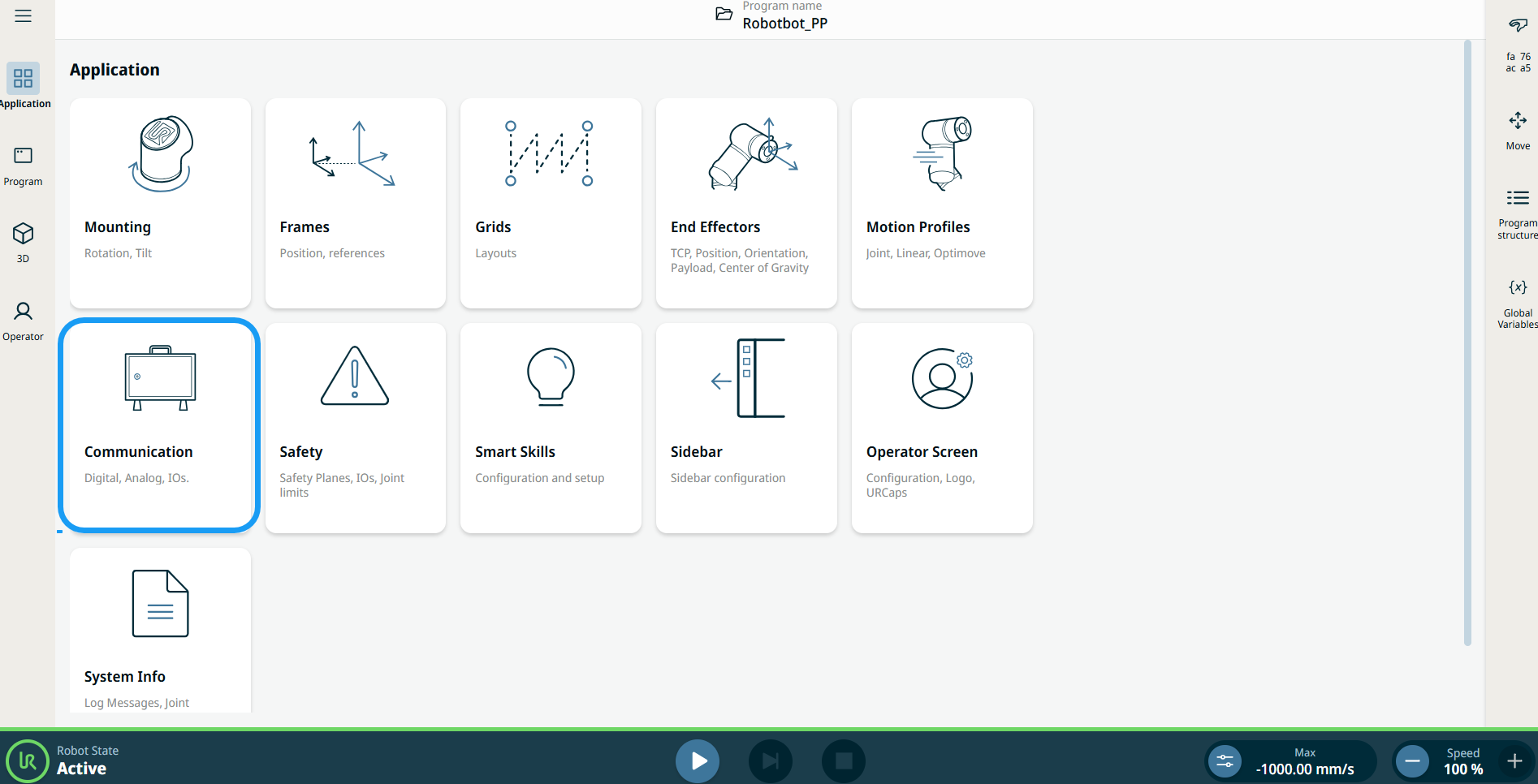

Communication

| Description |

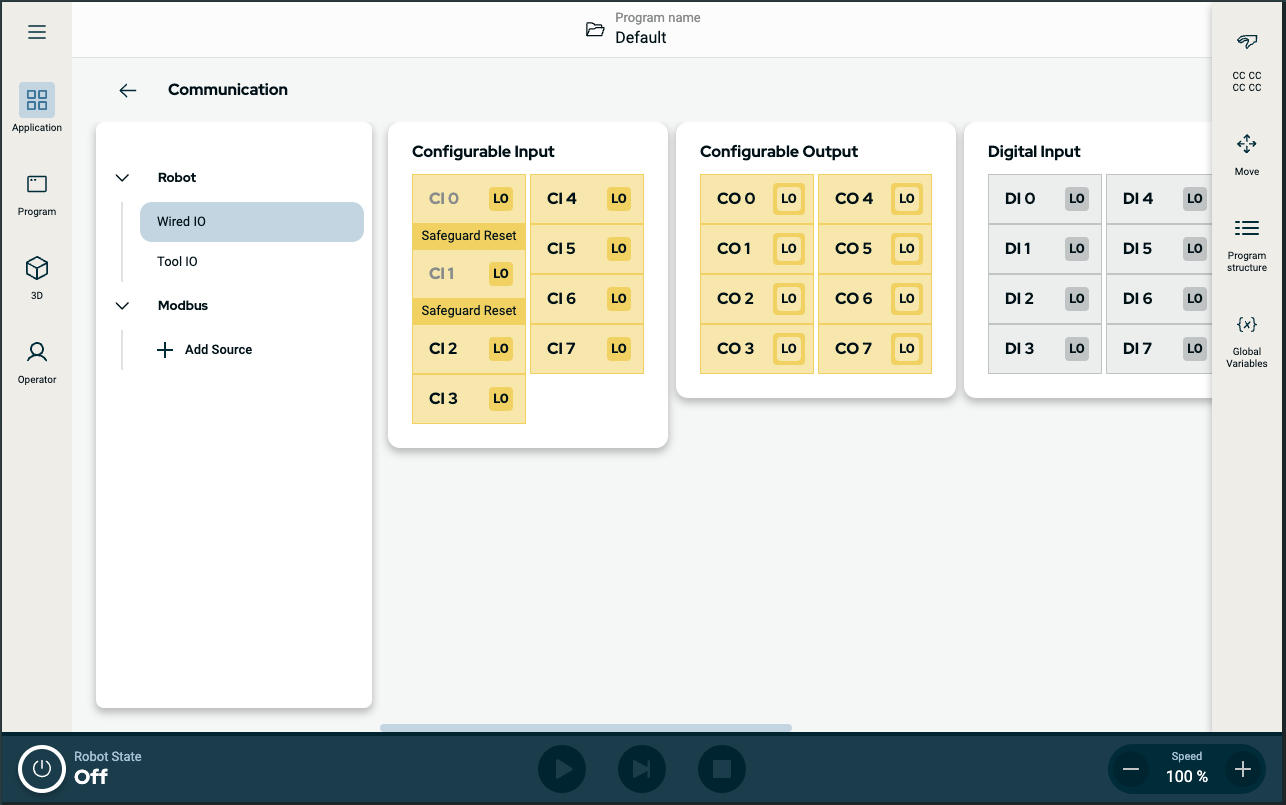

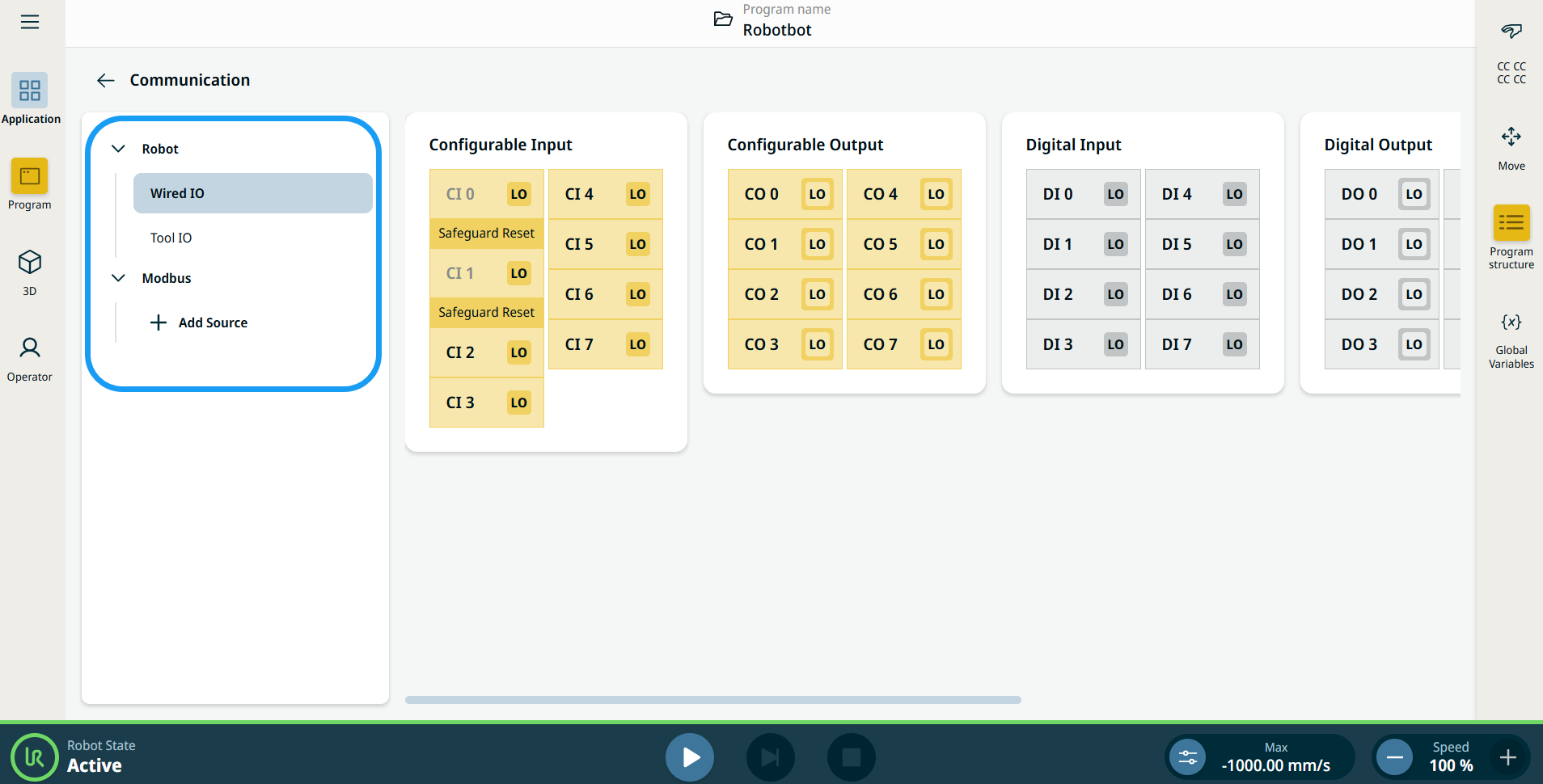

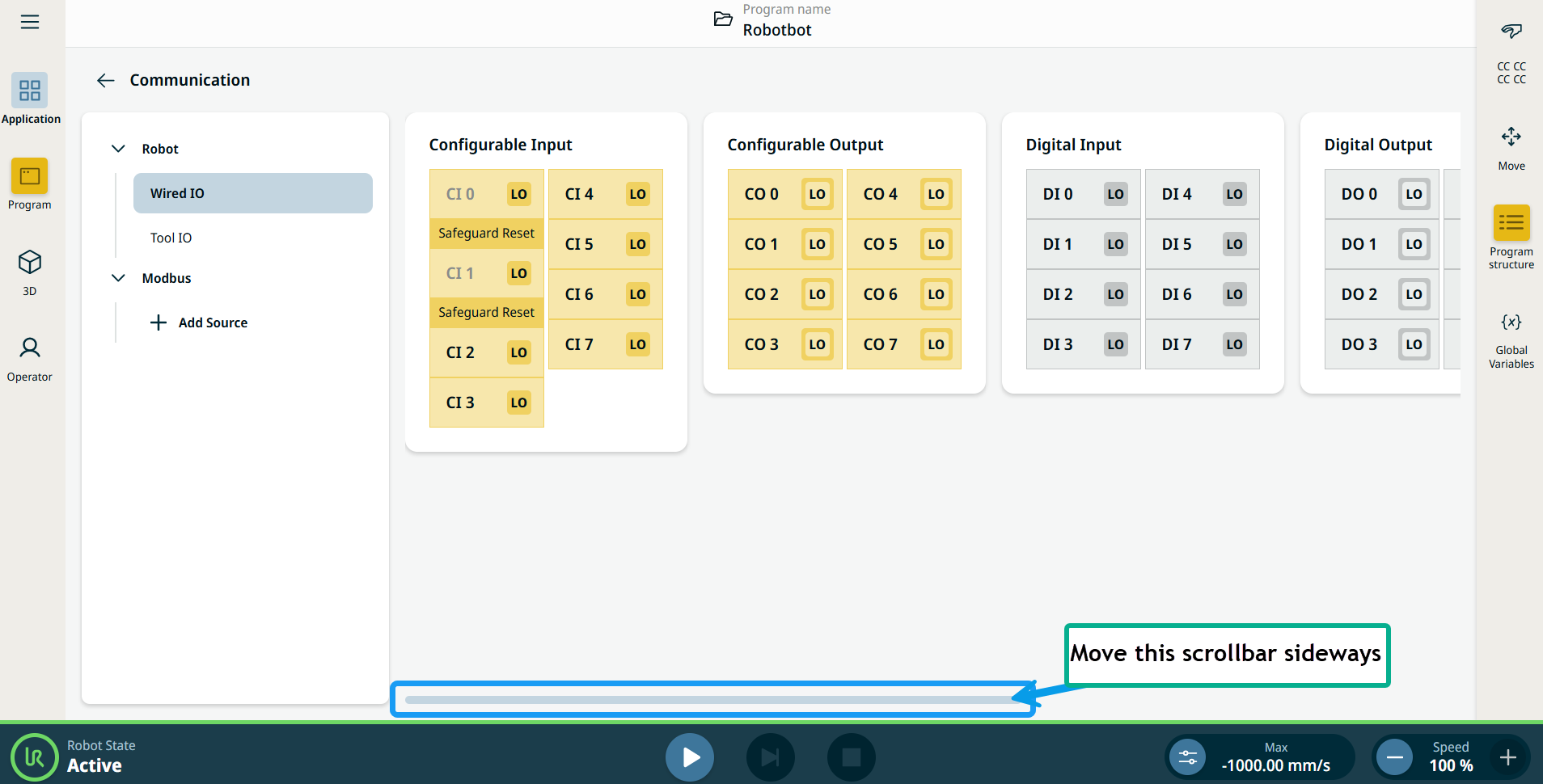

The Communication application allows you to monitor and set the live IO (input-output) signals from/to the robot control box.

|

|

Using the Communication application functionality |

|

|

To access Wired IO |

|

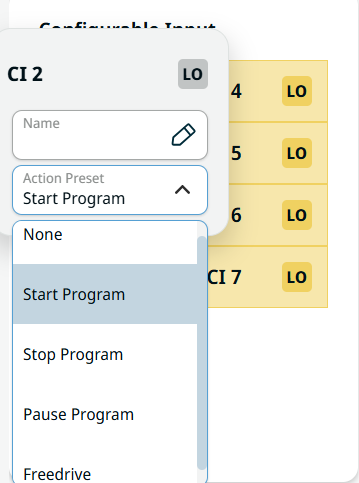

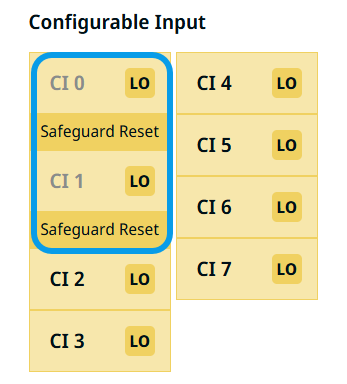

| Configurable Input |

Configurable input can be reserved for special safety settings defined in the IO Setup under Safety IO. Under those which are reserved for safety settings (CI 0 and CI 1), named Safeguard Reset, are in gray and cannot be edited. CI 2–CI 7 have editable fields.

|

|

|

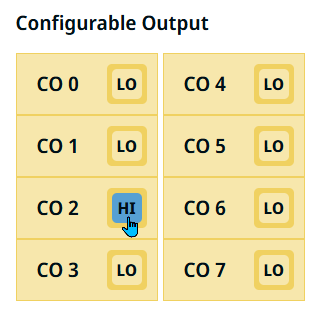

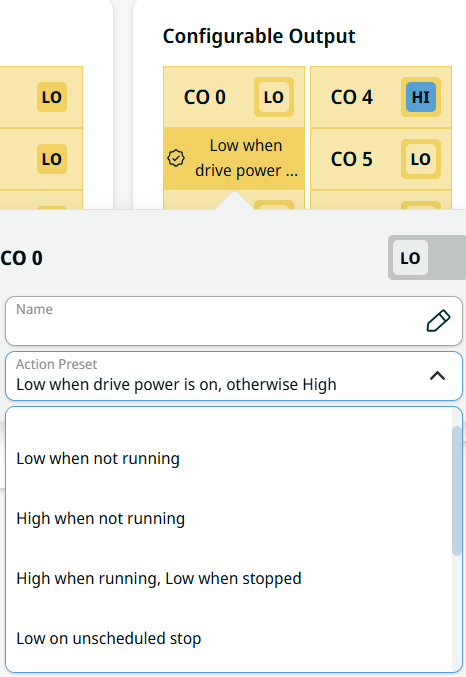

| Configurable Output |

The Configurable Output field ranges from CO 0 to CO 7.

|

|

|

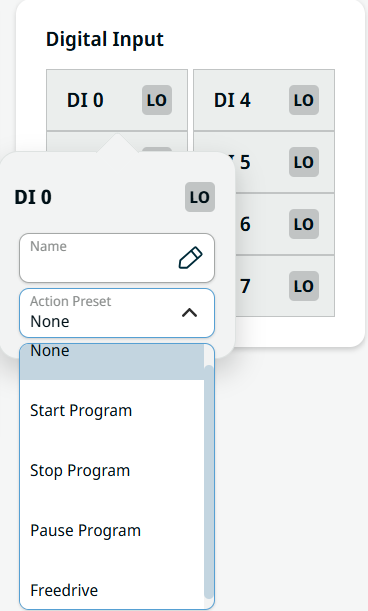

| Digital Input |

The Digital Input field ranges from DI 0 to DI 7.

|

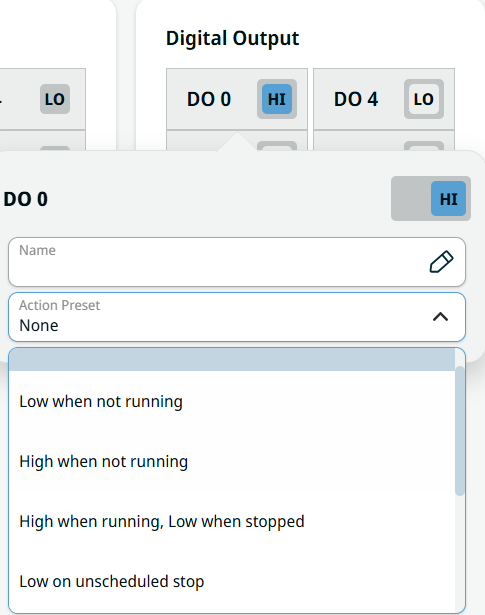

| Digital Output |

The Digital Output field ranges from DO 0 to DO 7 and are set independently to either high or low.

Follow all the steps as in Configurable Output. |

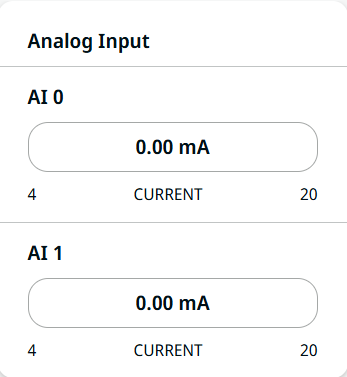

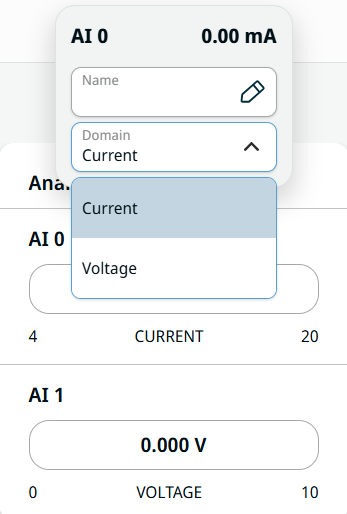

| Analog Input |

Analog input has two fields for AI 0 and AI 1. It can be set to 4–20 mA. These settings are persistent over restarts of the robot controller and saved in the installation.

|

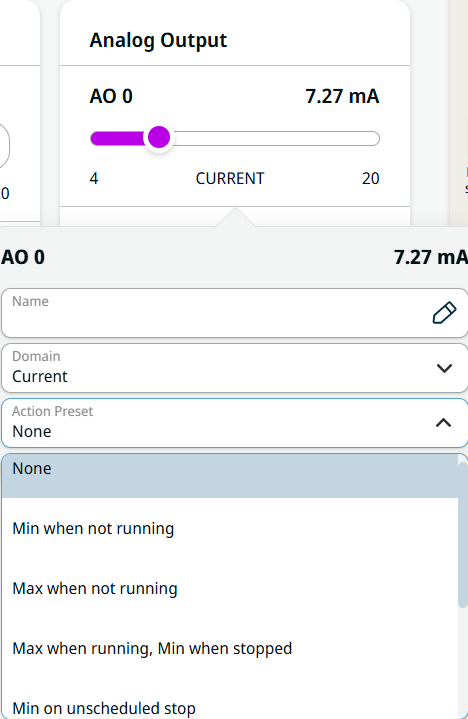

| Analog Output |

Analog output has two fields for AO 0 and AO 1. As with analog input, it can be set to 4–20 mA.

|

|

|

|

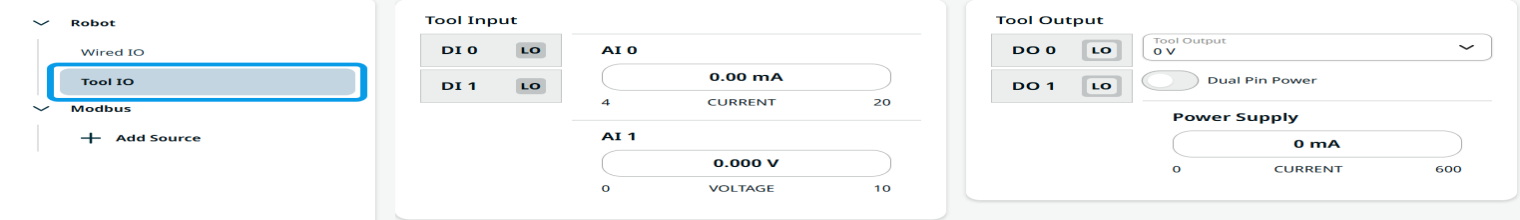

| To access Tool IO |

Tool IO monitors and sets the live IO signals from/to the control box.

Tap Tool IO on the left panel. You can see the editable fields of Tool Input and Tool Output on the right.

|

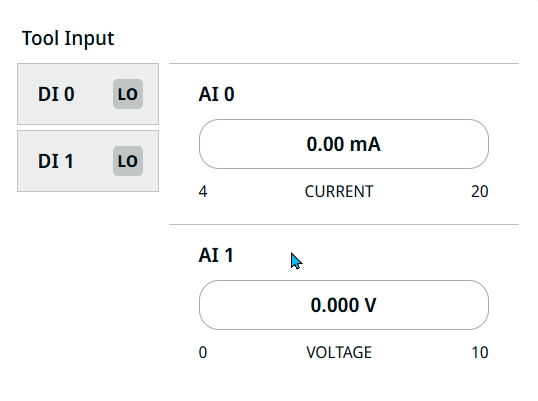

| Tool Input |

The Tool Input is composed of four fields:

|

|

|

|

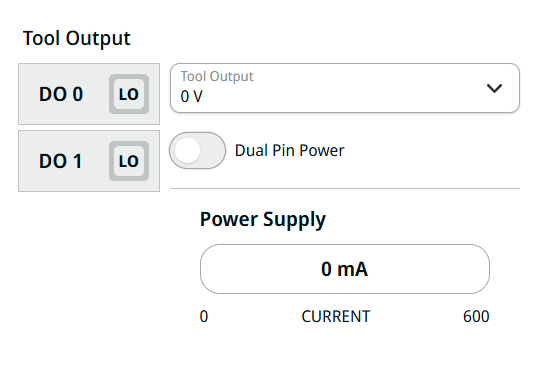

| Tool Output |

The Tool Output is composed of five fields:

|

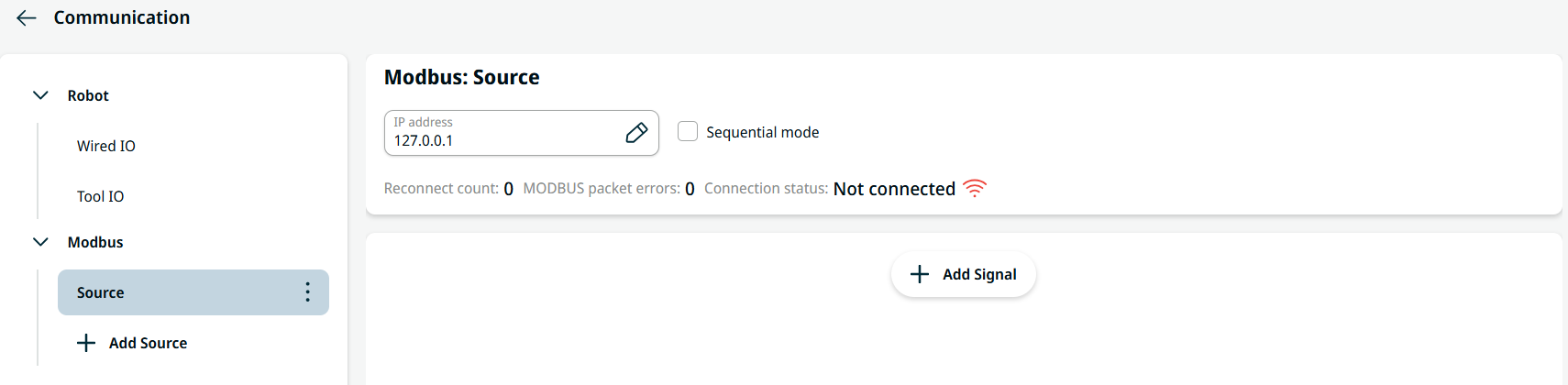

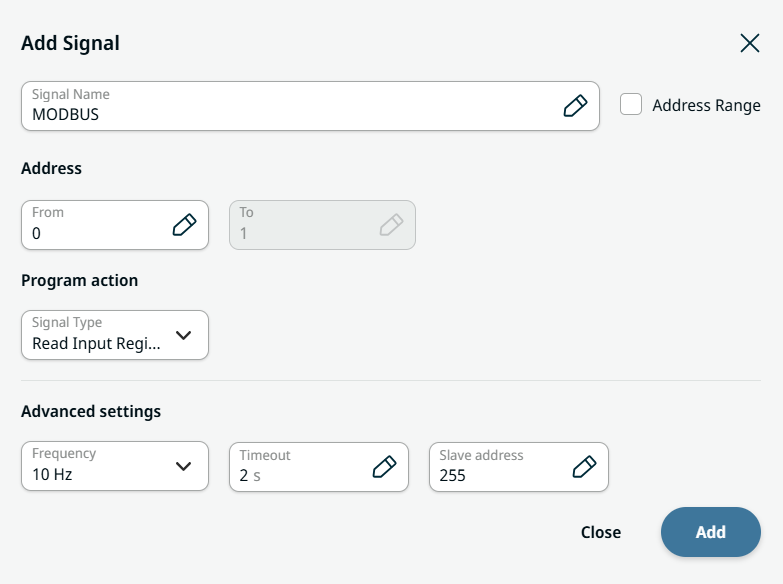

| Modbus |

Modbus is a serial communication protocol tied to a known IP address. It holds several input/output registers.

|

|