Changing/repair or modifying the robot cable

Changing/repair or modifying the robot cable on a CB3 robot arm.

THIS IS FOR CB-SERIES ONLY

A UR robot comes with a 6m cable only. There are no other options at the moment. If you have enquiries please contact your UR Distributor.

NOTE: Universal Robots cannot offer support on modifying the cable. Modifying the cable (making it shorter/longer, using different types of cable etc.) is the users own responsibility.

Changing the cable requires disassembling the robot.

Disassembling the robot makes the calibration invalid.

Cable on a standard UR robot

UR5 (Drawing 922050)

The cable on an UR5 has the following data:

Type: 2 x 2 x 1.0mm2 Twisted pair, PVC tin plated copper

Length: Approx. 6m

Diameter: 10.3 (+/-0.4)

Minimum fixed installation bending radius: 6x cable diameter (62mm)

Minimum flexing radius: 15x cable diameter (155mm)

Operating temperature: -30 to 70 Celsius

UR3 & UR10

The cable on an UR3/UR10 has the following data:

Type: 3 x 2 x 1.0mm2 Twisted pair, PVC tin plated copper

Length: Approx. 6m

Diameter: 10.4 (+/-0.4)

Minimum fixed installation bending radius: 6x cable diameter (62mm)

Minimum flexing radius: 15x cable diameter (155mm)

Operating temperature: -30 to 70 Celsius

The cable for an UR3, UR5 and UR10 is similar

The UR 3 and UR10 has 6 connections. 2x +48V, 2x 0V/GND and 2 connections for RS485 + shield.

The UR3 however has 2 of the 48V wires swapped to detect incorrect mounting, on a UR10 for example.

UR5 has 1 x 48V, 1 x 0V/GND and 2 connections for RS485 + shield

Important cable requirements

- The two communication (RS485) wires shall be twisted pair

- If the cable length is extended then the resistance of the power wires shall be no more than the original cable. (<100mOhm / wire)

- The cable shall have a shield which is connected to the housing in both robot and control box

Nice to know

- It is acceptable if the power wires are not twisted pairs.

- It is acceptable to split the cable into two cables. By doing so you can use a small cable for the communication and a very thick cable for the 48V power. Remember to connect both shields in both ends and keep the two cables along each other.

- If you make a wrong connection in the cable, you will not damage the robot when turning it on. If the communication is reversed the robot powers off immediately after pushing the ON button. And if the power lines are reversed you get a C50A101 or C50A103 "ROBOT POWERUP FAILURE" error.

Pitfalls and errors

- If you use a cable with to high resistance in the 48V wires the robot probably seem to work. But, if you use a high acceleration and/or a high speed you might get errors like C48AXX "Voltage drop detected". The error may also appear when the robot unlocks its breaks and some joints may end up in shutdown mode.

- If you do not use twisted pairs for the communication the robot probably seem to work. However, then you might not meet the requirements of the EMC standards (e.g. the EN 61000 series) and regulations. In noisy environments you might get some errors on the log screen, e.g. C4AXX "Broken communication error" or C11AXX "Bad CRC error". The robot tolerates few communication errors without stopping the robot program. If too many errors appear you get a "Too many errors in a row" error and the robot stops.

Connectors on a standard UR robot

Universal Robots does not supply individual parts in/on the cable between the controller and the robot.

However, the attached 3 pdf documents below will help you find the information you may need in order to source the parts locally.

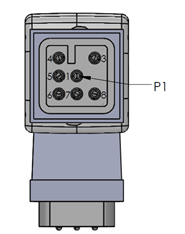

UR3 Pin out

The UR3 cable is connected to the robot with a square 7 pole connector for the control box.

| Color | function | connection b |

|

Yellow, Pink |

+48V |

P5, P6 |

|

Green, Gray |

0V |

P4, P7 |

|

White |

RS485+ |

P1 |

|

Brown |

RS485- |

P3 |

|

-- |

Shield |

P8 |

The smaller contacts are used for the six wires, and the larger contact is used for the shield connection.

In the other end, the six wires go into the screw terminal of the BaseFilterBoard. Yellow and Pink goes into the 48V terminals, Green and Gray go into the GND terminals, White goes into the M terminal, and Brown goes into the P terminal. The shield should be terminated to the base of the robot.

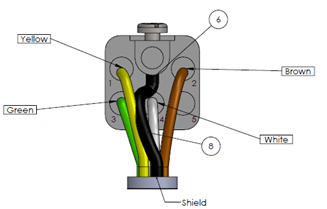

UR5 Pin out

The UR5 robot cable is attached to the robot, with a square 5-pole connector for the control box.

|

Color |

Function |

Connection B |

|

Brown |

0V |

P2 |

|

White |

+48V |

P4 |

|

Yellow |

RS485+ |

P1 |

|

Green |

RS485- |

P3 |

|

Black |

Shield |

-- |

The four Lapp contacts are for the four wires, the smaller ferrule is for the shield.

The other end connects directly into the base. It may be difficult to get a thicker cable in.

The white wire connects to the red wire from the base joint. The brown wire connects to the black wire of the base joint through a terminal on the base. The green and yellow wires are crimped and inserted into the house. The green wire goes into port 0, which has a small arrow. The Vogt ring terminal is for connecting the Shield to the base of the robot.

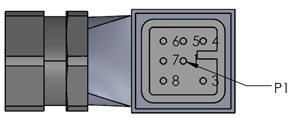

UR10 Pin out

The UR10 cable is separate from the robot and the controller with a square 7 pole connector at each end.

|

Color |

Function |

Connection B |

|

Yellow, Pink |

+48V |

P5, P7 |

|

Green, Gray |

0V |

P4, P6 |

|

White |

RS485+ |

P1 |

|

Brown |

RS485- |

P3 |

|

-- |

Shield |

P8 |

The smaller contacts are used for the six wires, and the larger contact is used for the shield connection.

Since the connectors have the same pin configuration, it is possible to use straight or angled connectors at either end.